Charger for Li-Ion (Li-Po) batteries from an “electronic cigarette”

Currently, “electronic cigarettes” are quite popular. But they often fail or are simply thrown away due to a dead battery or a broken power button. However, from this device you can make a good small-sized “charger” for Li-Ion (and not only!) batteries with a voltage of 3.6 (or 3.7) volts. In this case, the battery will be charged in an optimal mode, with control of the charging current and automatic shutdown of the charging process when the voltage reaches 4.2 volts (this is the maximum permissible voltage on a fully charged battery, without the risk of overheating and physical destruction).

To make such a charger, you will need any charging adapter for a cell phone with an output voltage of 5 volts, which will serve as a power source and housing. After disassembling the body of the “electronic cigarette”, a small electronic board will be revealed, approximately the same as shown in the figure.

This board has a micro-USB connector, and also has two wires coming out of it to the battery - “plus” (red) and “minus” (white or black). These wires should be carefully unsoldered and instead soldered a two-wire cable of the required length to connect subsequently charged batteries.

The case of the telephone “charger” should be opened and the electronic board removed from it, as shown in the figure.

Boards from other “chargers” may have a different appearance and size, but this does not matter, since they are functionally and in their parameters the same. We unsolder the cable with the connector from this board and instead of it with short wires we solder the micro-USB connector to connect to the board that we removed from the “electronic cigarette”. Such a connector can be taken, for example, from the same “charging” for cell phones. This way we will connect the output of the telephone “charging” to the charger board from the “electronic cigarette” without the need to solder small parts, which is quite difficult to do at home. And instead of the two wires that previously went to the “electronic cigarette” battery, we need to solder a cable of the length we need, as mentioned above. To the end of the cable you can solder any suitable connector for connecting chargeable batteries (you can solder several different connectors in parallel for connecting batteries with different contacts).

In the cases of telephone “chargers” there is usually enough space for a small board from an “electronic cigarette” to fit there during assembly (if you do not take too compact “chargers”), so we place this board where there is free space for it.There is no need to fasten it in any way, it is only important to prevent the parts of both boards from touching each other, for which you can use electrical tape, sealant, pieces of cardboard or any other insulating materials. It is important to note that the electronic cigarette board has an LED indicator that visually displays the status of the entire charger - plugged in (three blue flashes), the charging process (lit in red) and the end of charging (Light-emitting diode goes out). In order to control the glow of this LED, a small “window” should be made in the case - a hole that can be closed with a piece of transparent plastic (or simply left open, which will provide some ventilation for the boards). This hole must be made opposite the place where it will be located Light-emitting diode after assembling the entire device.

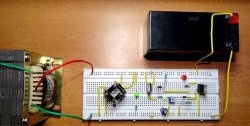

This way we will get a good charger for any batteries with a voltage of 3.6 (or 3.7) volts with small dimensions and the function of full control of the charging process. The appearance of the finished charger is shown in the figure.

To make such a charger, you will need any charging adapter for a cell phone with an output voltage of 5 volts, which will serve as a power source and housing. After disassembling the body of the “electronic cigarette”, a small electronic board will be revealed, approximately the same as shown in the figure.

This board has a micro-USB connector, and also has two wires coming out of it to the battery - “plus” (red) and “minus” (white or black). These wires should be carefully unsoldered and instead soldered a two-wire cable of the required length to connect subsequently charged batteries.

The case of the telephone “charger” should be opened and the electronic board removed from it, as shown in the figure.

Boards from other “chargers” may have a different appearance and size, but this does not matter, since they are functionally and in their parameters the same. We unsolder the cable with the connector from this board and instead of it with short wires we solder the micro-USB connector to connect to the board that we removed from the “electronic cigarette”. Such a connector can be taken, for example, from the same “charging” for cell phones. This way we will connect the output of the telephone “charging” to the charger board from the “electronic cigarette” without the need to solder small parts, which is quite difficult to do at home. And instead of the two wires that previously went to the “electronic cigarette” battery, we need to solder a cable of the length we need, as mentioned above. To the end of the cable you can solder any suitable connector for connecting chargeable batteries (you can solder several different connectors in parallel for connecting batteries with different contacts).

In the cases of telephone “chargers” there is usually enough space for a small board from an “electronic cigarette” to fit there during assembly (if you do not take too compact “chargers”), so we place this board where there is free space for it.There is no need to fasten it in any way, it is only important to prevent the parts of both boards from touching each other, for which you can use electrical tape, sealant, pieces of cardboard or any other insulating materials. It is important to note that the electronic cigarette board has an LED indicator that visually displays the status of the entire charger - plugged in (three blue flashes), the charging process (lit in red) and the end of charging (Light-emitting diode goes out). In order to control the glow of this LED, a small “window” should be made in the case - a hole that can be closed with a piece of transparent plastic (or simply left open, which will provide some ventilation for the boards). This hole must be made opposite the place where it will be located Light-emitting diode after assembling the entire device.

This way we will get a good charger for any batteries with a voltage of 3.6 (or 3.7) volts with small dimensions and the function of full control of the charging process. The appearance of the finished charger is shown in the figure.

Similar master classes

Particularly interesting

Comments (4)