Balancing charger for Li-ion

There are a lot of chargers on the market now. Automatic machines or not, with or without capacitance measurement. Most chargers are universal and can charge elements of any chemistry. Lithium ion and lithium polymer are increasingly used in various devices.

Not long ago I converted the screwdriver battery to lithium-ion 18650 cells. I charge it with a Turnigy smart charger. But not everyone has this charger.

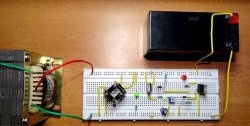

I decided to assemble a simple charger with a balancer for lithium-ion. The charger has 3 identical independent channels. They can charge from one element to three. If necessary, you can add any number of channels. I have three of them, that is, 3S or 11.1 volts.

The case for the balancing charger is the case from a burned-out D-link router. If possible, take a larger case; it becomes very cramped to work in it.

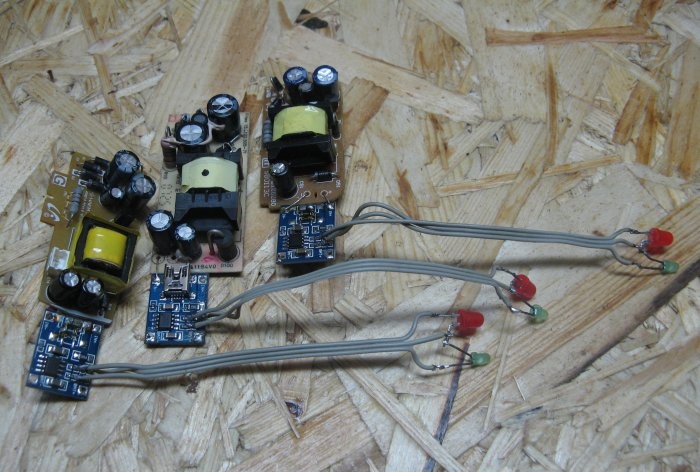

One of the main components is the power supply for each channel.Their role is played by tablet charger boards, with an output of 5 Volts and a current of 1 Ampere (or can be bought on Ali Express - switching power supply 5 V 1 A).

The charge controllers are boards from China - charge controller for 18650 battery. Each channel has its own controller. I have boards without protection, but in this case it is not needed. You can use controller boards together with connectors; I don’t have them on two of them; they were removed for other projects. The price for these modules is cheap. If you are modifying devices based on lithium-ion and lithium-polymer, then these controllers are indispensable.

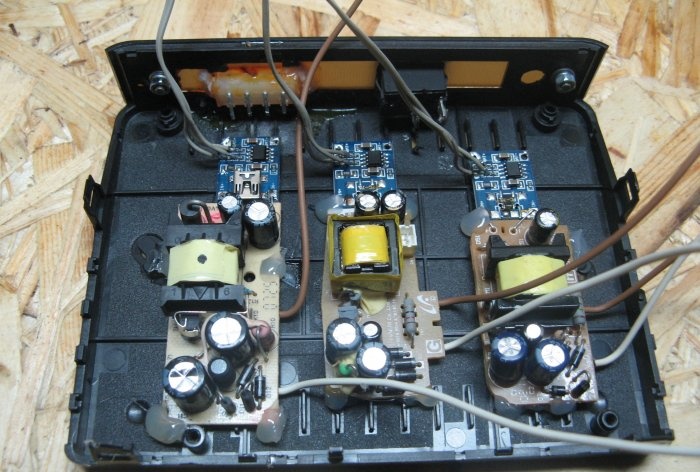

The charge controller boards need to be soldered to the outputs of the charging boards. It can be done separately. I soldered it on thick wires from the power cable, so the structure is more rigid.

Charge controller boards have LEDs, which indicate the charge and the end of the charge. They need to be desoldered. There will be regular ones instead LEDs, different color. They will be attached to the windows where they used to blink LEDs router.

I soldered wires from an old computer hard drive cable to the LEDs. If there LEDs with a common anode (plus), it is better to use them. I didn’t have any of these, so I used what I had.

In place of the old ones LEDs, solder the cables with LEDs. In the photo I have a 3mm green LED. I had to replace them, they turned out to be scorched, I didn’t check them before unsoldering.

For the back panel you need to cut out the trim. We make cuts in it for the power switch and the 4-pin output connector. The connector was removed from an old hard drive. You can use any one for the required number of pins, with a current of 1-2 Amperes.

The switch was removed from the old computer power supply. We fasten the cover with two screws for rigidity.

We glue the output connector with epoxy glue or soda with super glue. For speed, I glued both one and the other.

Charging board with controllers, glued with thermal glue. But before fixing, I soldered the network wires.

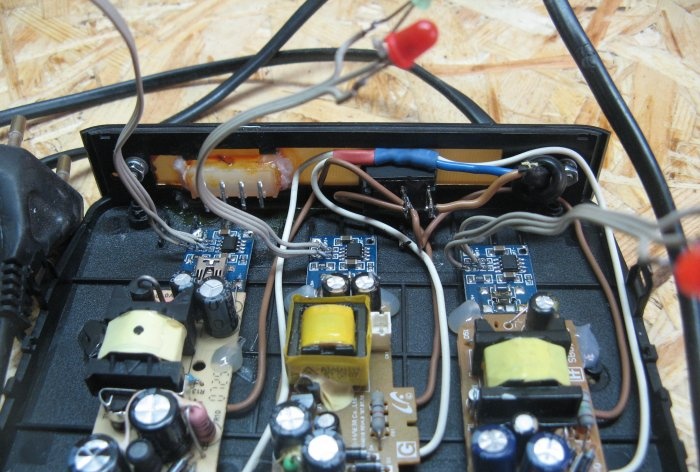

We solder one of the network wires to the switch. The second, directly to the second wire of the power cord.

Now we glue the LEDs. I glued it with hot glue, or you can use baking soda and super glue.

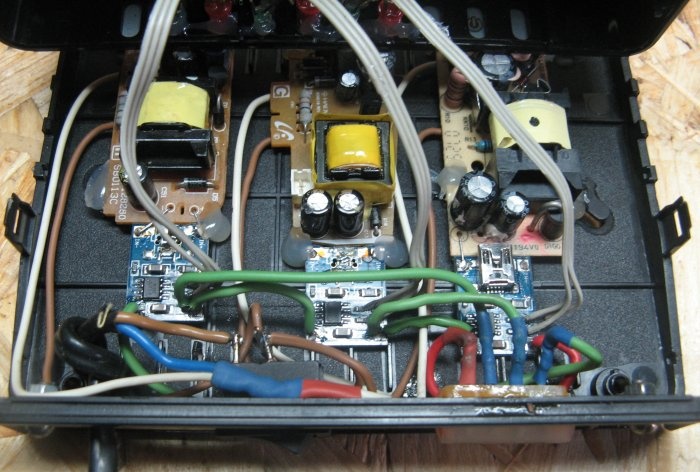

Solder the output jumpers.

Plus the first controller on the first leg of the output connector. Minus it on the second leg and connect it to the plus of the second controller. And so on.

We twist the body and put it aside.

Let's make a wire for this charger.

I used two pieces of wire from the computer power supply. I soldered it in order from the first contact of one connector to the contact of the second.

Connect the charger to the screwdriver battery (Converting a screwdriver battery to lithium). The red LED indicates the charging process is in progress. When charging is complete, the green LED lights up. Accordingly, the icons on the case light up: Wi-Fi, second and fourth computers.

This is the charger we got. The costs are minimal, but the benefits are great.

This device can charge lithium polymer assemblies, those that modelers use in their vehicles. The main thing is to make the correct charging wire.

Not long ago I converted the screwdriver battery to lithium-ion 18650 cells. I charge it with a Turnigy smart charger. But not everyone has this charger.

Needed for assembly

I decided to assemble a simple charger with a balancer for lithium-ion. The charger has 3 identical independent channels. They can charge from one element to three. If necessary, you can add any number of channels. I have three of them, that is, 3S or 11.1 volts.

The case for the balancing charger is the case from a burned-out D-link router. If possible, take a larger case; it becomes very cramped to work in it.

One of the main components is the power supply for each channel.Their role is played by tablet charger boards, with an output of 5 Volts and a current of 1 Ampere (or can be bought on Ali Express - switching power supply 5 V 1 A).

The charge controllers are boards from China - charge controller for 18650 battery. Each channel has its own controller. I have boards without protection, but in this case it is not needed. You can use controller boards together with connectors; I don’t have them on two of them; they were removed for other projects. The price for these modules is cheap. If you are modifying devices based on lithium-ion and lithium-polymer, then these controllers are indispensable.

Making a balancing charger

The charge controller boards need to be soldered to the outputs of the charging boards. It can be done separately. I soldered it on thick wires from the power cable, so the structure is more rigid.

Charge controller boards have LEDs, which indicate the charge and the end of the charge. They need to be desoldered. There will be regular ones instead LEDs, different color. They will be attached to the windows where they used to blink LEDs router.

I soldered wires from an old computer hard drive cable to the LEDs. If there LEDs with a common anode (plus), it is better to use them. I didn’t have any of these, so I used what I had.

In place of the old ones LEDs, solder the cables with LEDs. In the photo I have a 3mm green LED. I had to replace them, they turned out to be scorched, I didn’t check them before unsoldering.

For the back panel you need to cut out the trim. We make cuts in it for the power switch and the 4-pin output connector. The connector was removed from an old hard drive. You can use any one for the required number of pins, with a current of 1-2 Amperes.

The switch was removed from the old computer power supply. We fasten the cover with two screws for rigidity.

We glue the output connector with epoxy glue or soda with super glue. For speed, I glued both one and the other.

Charging board with controllers, glued with thermal glue. But before fixing, I soldered the network wires.

We solder one of the network wires to the switch. The second, directly to the second wire of the power cord.

Now we glue the LEDs. I glued it with hot glue, or you can use baking soda and super glue.

Solder the output jumpers.

Plus the first controller on the first leg of the output connector. Minus it on the second leg and connect it to the plus of the second controller. And so on.

We twist the body and put it aside.

Let's make a wire for this charger.

I used two pieces of wire from the computer power supply. I soldered it in order from the first contact of one connector to the contact of the second.

Connect the charger to the screwdriver battery (Converting a screwdriver battery to lithium). The red LED indicates the charging process is in progress. When charging is complete, the green LED lights up. Accordingly, the icons on the case light up: Wi-Fi, second and fourth computers.

This is the charger we got. The costs are minimal, but the benefits are great.

This device can charge lithium polymer assemblies, those that modelers use in their vehicles. The main thing is to make the correct charging wire.

Watch the video

Similar master classes

Particularly interesting

Comments (0)