How to make a hacksaw machine for metal

Sometimes there is a need to urgently cut off a piece of metal, but you only have a piece of cloth at hand. It is very inconvenient to work without a machine; the blade not only cuts your hand, but will definitely break, unless, of course, it is a product of Chinese defectors. Their metal bends in an arc, does not break, but does not saw. Real alloy tool steel undergoes additional heat treatment and does not bend; it is not designed for such conditions. There is a way out - you can make a basic machine yourself.

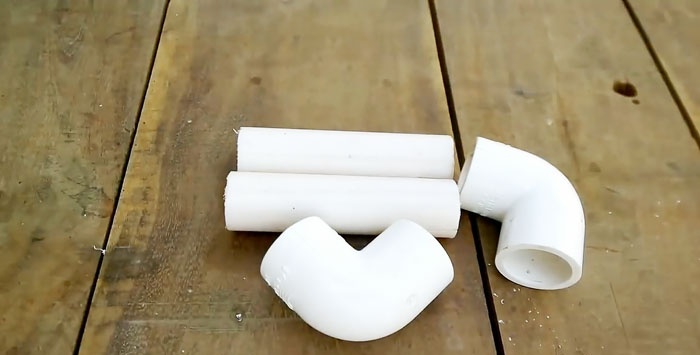

To make the machine you will need a piece of plastic pipe, two angles and measuring tools. The diameter of the pipe is at least 3/4 inch, thinner ones are bendable. The length must exceed the dimensions of the canvas by at least 20 cm.

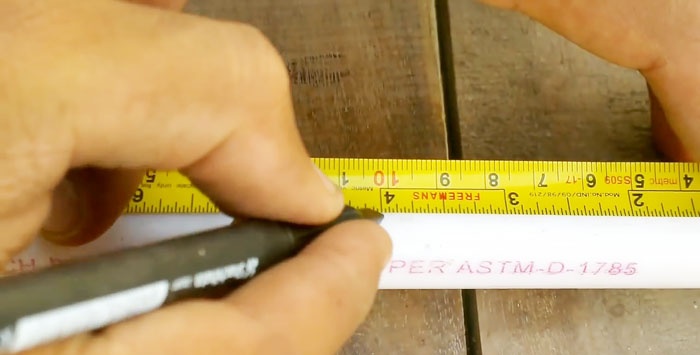

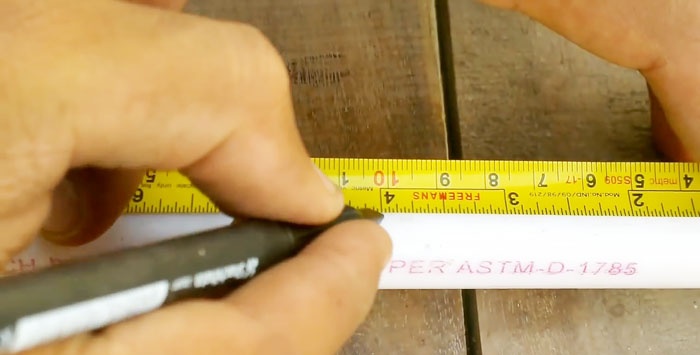

Cut two pieces of 10 cm from the pipe, the pieces should be the same.

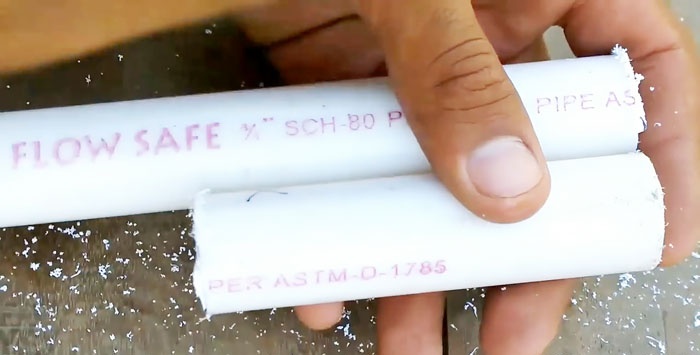

In order to maintain an approximate angle, draw marks along the entire circumference. Anyone with experience will make an almost perfect stripe. A plastic pipe can be cut with one blade, you just need to constantly keep it in a vertical position and follow the marks.

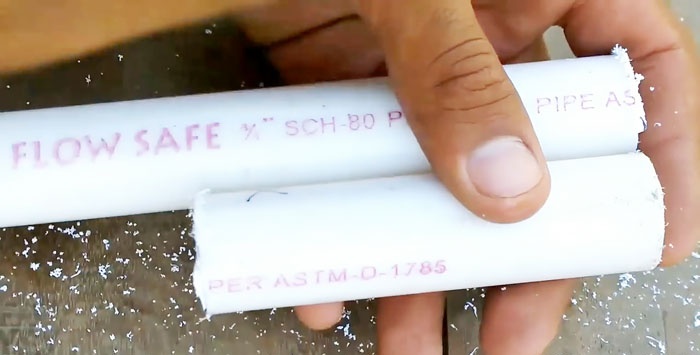

On short tubes, you need to cut slits approximately 1.5 cm long; they are located along the diameter and on the line of symmetry.There is no need to measure accurately; do everything by eye.

Clamp the tubes in a vice, align the marks and cut the slots. There are no vices - you can do it without them, but you will have to put in a little more effort.

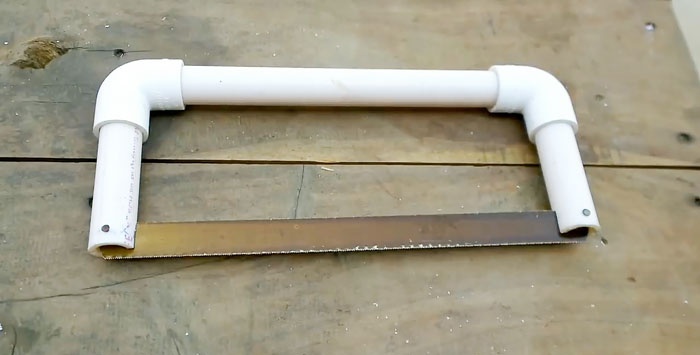

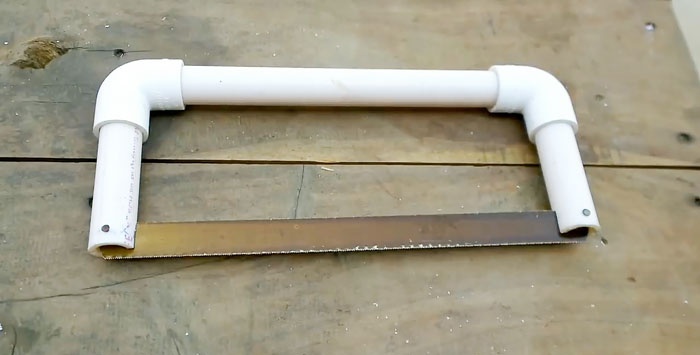

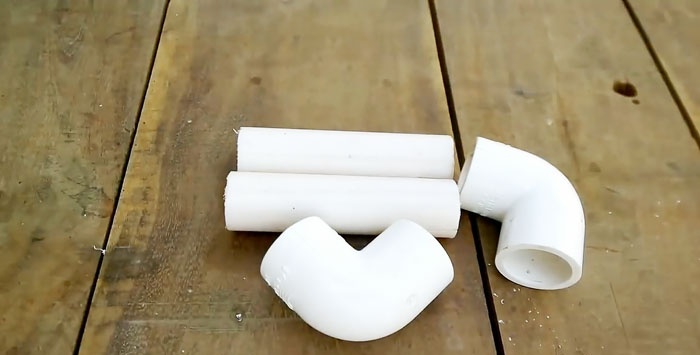

Place the corners on the ends of the long tube, insert short ones from the other end.

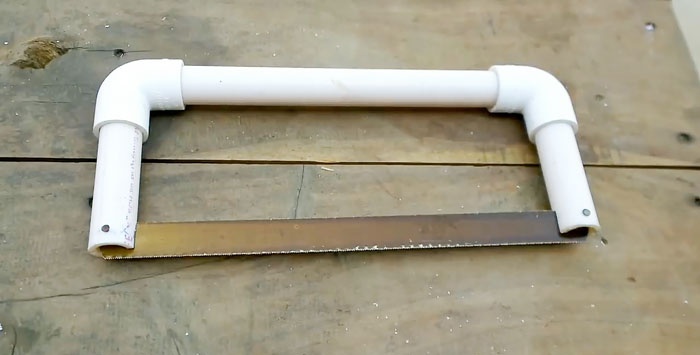

Lay the structure on a flat surface and mark the locations of the holes. Carefully check the dimensions again, place the canvas, its technological fixation points should be located opposite the holes.

Using a drill with a diameter of approximately 1 mm, drill a hole in one wall of each short section. Insert a hacksaw blade into the slots and secure it with small nails. The tool is ready to use, you can cut metal.

If the angles in the tube do not sit firmly, then you need to glue them; today there are many very high-quality compounds. One more tip. The length of the nails should be such that the sharp end rests against the opposite wall of the tube; hammer them in until they are securely fixed. You can not hammer them, but heat them and insert them hot. The metal will make holes in the plastic and will be firmly fixed, the canvas will not jump out.

[media=https://www.youtube.com/watch?v=QBK197XBTo4]

What you need to have

To make the machine you will need a piece of plastic pipe, two angles and measuring tools. The diameter of the pipe is at least 3/4 inch, thinner ones are bendable. The length must exceed the dimensions of the canvas by at least 20 cm.

Manufacturing technology

Cut two pieces of 10 cm from the pipe, the pieces should be the same.

In order to maintain an approximate angle, draw marks along the entire circumference. Anyone with experience will make an almost perfect stripe. A plastic pipe can be cut with one blade, you just need to constantly keep it in a vertical position and follow the marks.

On short tubes, you need to cut slits approximately 1.5 cm long; they are located along the diameter and on the line of symmetry.There is no need to measure accurately; do everything by eye.

Clamp the tubes in a vice, align the marks and cut the slots. There are no vices - you can do it without them, but you will have to put in a little more effort.

Place the corners on the ends of the long tube, insert short ones from the other end.

Lay the structure on a flat surface and mark the locations of the holes. Carefully check the dimensions again, place the canvas, its technological fixation points should be located opposite the holes.

Using a drill with a diameter of approximately 1 mm, drill a hole in one wall of each short section. Insert a hacksaw blade into the slots and secure it with small nails. The tool is ready to use, you can cut metal.

Conclusion

If the angles in the tube do not sit firmly, then you need to glue them; today there are many very high-quality compounds. One more tip. The length of the nails should be such that the sharp end rests against the opposite wall of the tube; hammer them in until they are securely fixed. You can not hammer them, but heat them and insert them hot. The metal will make holes in the plastic and will be firmly fixed, the canvas will not jump out.

Watch the video

[media=https://www.youtube.com/watch?v=QBK197XBTo4]

Similar master classes

Machine for cutting metal from an electric meat grinder

Plastic pipe drilling machine

Method for shortening a hacksaw blade for metal

How to make a mini metal bending machine

A simple device for picking fruit from a height from a PVC pipe

How to make a shaped vegetable knife from a piece of PVC pipe

Particularly interesting

Comments (1)