How to turn a timing gear into a full-fledged wood cutter

Everything contributes to such a metamorphosis: metal, size ratio, the presence of straight or oblique teeth, etc. In a word, a timing gear from a passenger car can serve as an ideal blank for making an end mill for wood.

In addition to the mentioned gear, we will need a small piece of steel pipe and a bolted connection commensurate with the transverse size of the timing gear mounting hole.

In our work we will have to use the following tools and equipment:

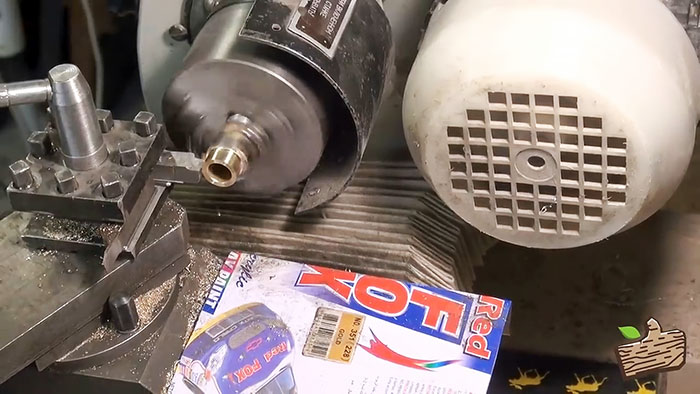

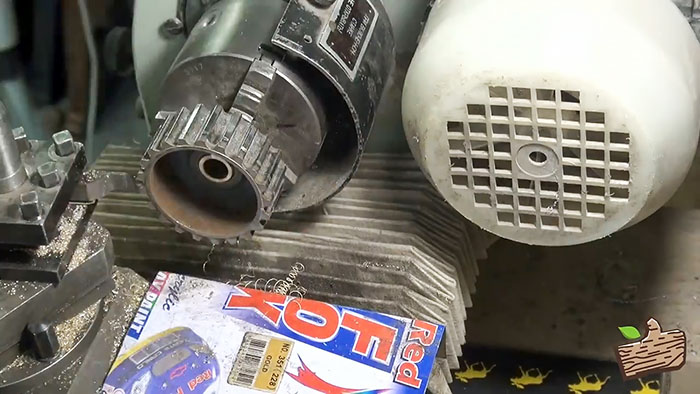

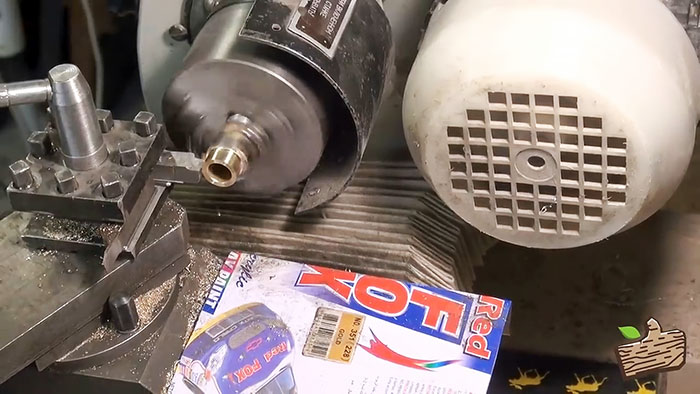

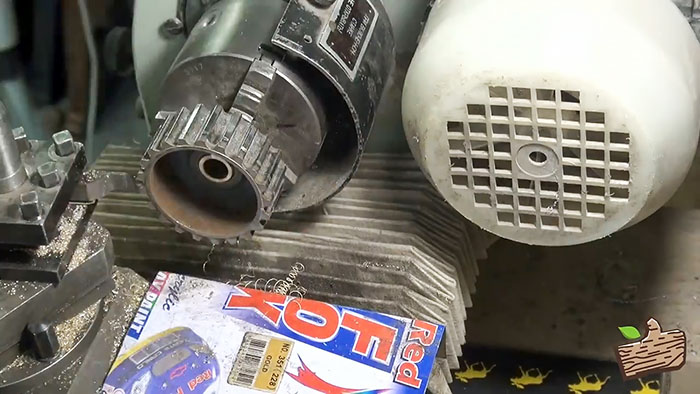

In order to eliminate runout of the gear when processing on a lathe, we clamp a metal tube in the chuck and grind its end to the diameter of the gear mounting hole.

We install it on the turned end of the tube, press it with the tailstock and process the end of the workpiece.

Let's proceed to the most important operation - cutting teeth on the gear. To do this, it must be securely secured in a vice, which is not easy to do without a special holder.

It's not difficult to make. We insert a bolt of suitable diameter and length into the mounting hole of the gear, on the other side of the workpiece we put a washer on the bolt, then a bushing, and tighten the resulting assembly with a nut using an adjustable wrench.

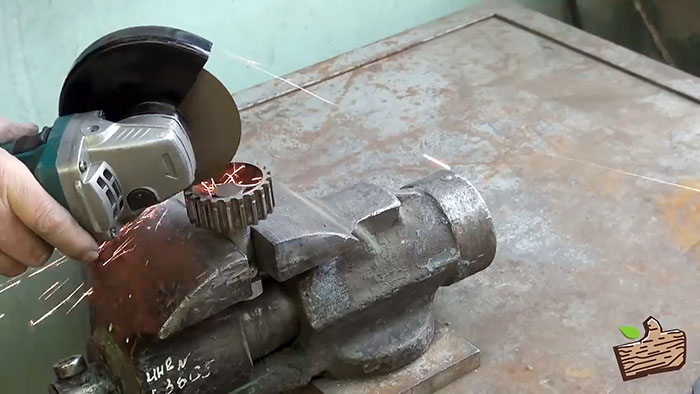

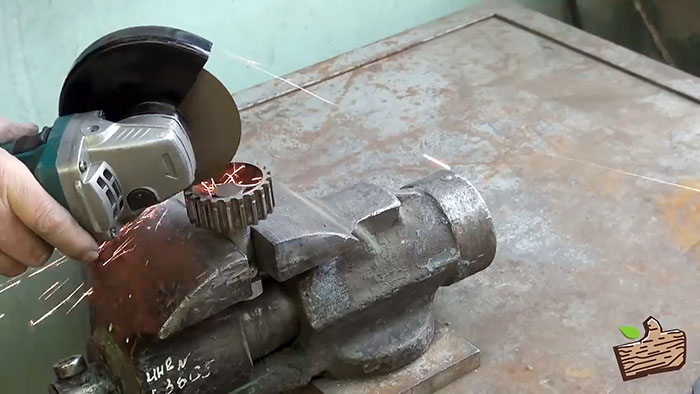

Now it is possible to securely secure the gear blank to the holder in a vice and use a grinder to cut grooves of the same depth along all the cavities of the gear. They will determine the height of the teeth and the sharpening angle of the future cutter.

After cutting the grooves in the workpiece, we disassemble the holder, removing the nut and bushing. We clamp the bolt rod in a vice so that the gear is on the side and can be rotated with a wrench around the bolt located horizontally.

Having set the calculated sharpening angle, using a grinder we cut the cutting teeth of the future cutter on the end surface of the gear.

Having laid the gear with the bolt flat on a bench vice, we remove the burrs and give the teeth their final shape, first with a file with a coarse notch, and then with a fine one.

We completely reinstall the holder onto the workpiece gear and use a gas-acetylene welding cutter to heat it until it begins to turn red, and then sharply lower it into a container of water.

We check the hardness of the hardening and notice that the metal is not hardened enough, since it can be processed with a finely cut file.

We heat the workpiece again, but at a higher temperature, and bring the metal to a bright red glow, after which we immerse the almost finished cutter in a container with water for quenching.

We grind a smaller one from the bushing for the holder to compensate for the diameter of the mounting hole of our cutter, 16 mm, and the diameter of the spindle of the angle grinder, 14 mm.

We remove the cutting disc from the angle grinder spindle, install the adapter sleeve and on it a homemade cutter made from the timing gear, and secure everything with a clamping nut.

We securely press a piece of board to the workbench table using a clamp, turn on the grinder and check it at idle speed without load. The tool works smoothly and no vibration is felt.

We increase the speed and begin to mill the surface of the board. We immediately feel a noticeable load on our hands, which indicates that a lot of wood is being removed. For convenience and safety of work, we screw the side handle into the angle grinder body.

If the work to be done is delicate, then the sharpening angle of the teeth of a homemade cutter should be made smaller; to increase productivity, on the contrary, it should be made larger.

Will need

In addition to the mentioned gear, we will need a small piece of steel pipe and a bolted connection commensurate with the transverse size of the timing gear mounting hole.

In our work we will have to use the following tools and equipment:

- lathe and grinder;

- calipers;

- metal files with coarse and fine cuts;

- bench vice and clamp;

- adjustable wrench and hammer;

- gas-acetylene welding;

- container with water.

The procedure for making a wood cutter from a timing gear

In order to eliminate runout of the gear when processing on a lathe, we clamp a metal tube in the chuck and grind its end to the diameter of the gear mounting hole.

We install it on the turned end of the tube, press it with the tailstock and process the end of the workpiece.

Let's proceed to the most important operation - cutting teeth on the gear. To do this, it must be securely secured in a vice, which is not easy to do without a special holder.

It's not difficult to make. We insert a bolt of suitable diameter and length into the mounting hole of the gear, on the other side of the workpiece we put a washer on the bolt, then a bushing, and tighten the resulting assembly with a nut using an adjustable wrench.

Now it is possible to securely secure the gear blank to the holder in a vice and use a grinder to cut grooves of the same depth along all the cavities of the gear. They will determine the height of the teeth and the sharpening angle of the future cutter.

After cutting the grooves in the workpiece, we disassemble the holder, removing the nut and bushing. We clamp the bolt rod in a vice so that the gear is on the side and can be rotated with a wrench around the bolt located horizontally.

Having set the calculated sharpening angle, using a grinder we cut the cutting teeth of the future cutter on the end surface of the gear.

Having laid the gear with the bolt flat on a bench vice, we remove the burrs and give the teeth their final shape, first with a file with a coarse notch, and then with a fine one.

We completely reinstall the holder onto the workpiece gear and use a gas-acetylene welding cutter to heat it until it begins to turn red, and then sharply lower it into a container of water.

We check the hardness of the hardening and notice that the metal is not hardened enough, since it can be processed with a finely cut file.

We heat the workpiece again, but at a higher temperature, and bring the metal to a bright red glow, after which we immerse the almost finished cutter in a container with water for quenching.

We grind a smaller one from the bushing for the holder to compensate for the diameter of the mounting hole of our cutter, 16 mm, and the diameter of the spindle of the angle grinder, 14 mm.

Testing a homemade wood cutter

We remove the cutting disc from the angle grinder spindle, install the adapter sleeve and on it a homemade cutter made from the timing gear, and secure everything with a clamping nut.

We securely press a piece of board to the workbench table using a clamp, turn on the grinder and check it at idle speed without load. The tool works smoothly and no vibration is felt.

We increase the speed and begin to mill the surface of the board. We immediately feel a noticeable load on our hands, which indicates that a lot of wood is being removed. For convenience and safety of work, we screw the side handle into the angle grinder body.

If the work to be done is delicate, then the sharpening angle of the teeth of a homemade cutter should be made smaller; to increase productivity, on the contrary, it should be made larger.

Watch the video

Similar master classes

Particularly interesting

Comments (6)