3 crafts from pieces of plastic pipes

Most households have pieces of plastic pipes that remain after various repairs. It’s a shame to throw it away, but I’m tired of moving it from place to place. There is a way out - to make three very necessary ones from them crafts.

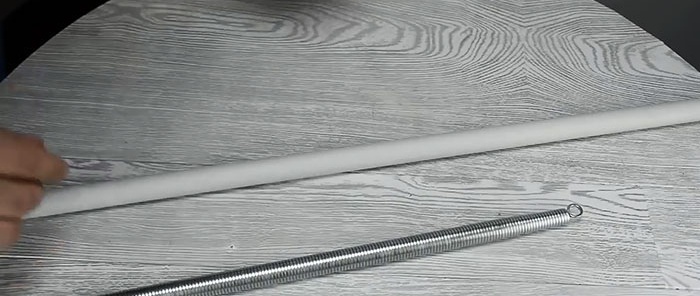

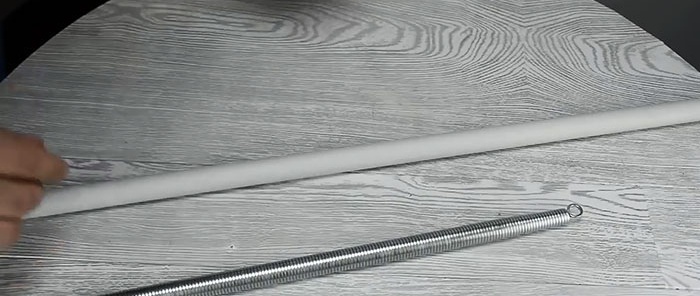

In addition to pieces of plastic pipe with a diameter of 3/4 and 1/2 inches, you must have nichrome wire with a diameter of 0.3–0.5 mm and a length of 30–40 cm, a voltage transformer of 12 V or 24 V, a metal spring and a powerful household or industrial hair dryer . The diameter of the spring must allow it to fit into the nominal hole of the pipe. The pipe is cut with special scissors. Holes are made using a screwdriver with drills or stones. Electrical installation work is carried out using a flexible cable; caps from plastic bottles are used for plugs. Insulation of connections is done with heat-shrinkable sections.

Insert a pipe bending spring into the pipe. The length of the segment is approximately 70 cm.

Use a hair dryer to evenly heat the surface of the pipe and bend it at a distance of approximately 25 cm from the end. Make a loop about 15 cm long in the upper part, press the end against the pipe.

Heat the remaining piece again and bend it at an angle of 90 degrees, you will get one arm for fixing the wire. After each bend, do not forget to pull out the spring.

Bend the second end of the tube; the length of the arm should be approximately equal to the parameters of the first. Using special scissors, trim the length of the ends of the device.

Make a hole at the turn of the handle, use a screwdriver and a nozzle with a stone. Insert two pieces of flexible cable into the hole. They must exit from two risers.

Make holes in the plastic covers. Insert a hook with an M6 thread into them, screw the nuts on the back side and firmly fix the wires.

Place the prepared plugs on the ends of the device. Solder the adapter (transformer) to the wires; protect the connection points with heat-shrinkable tubing. Glue them to the wall of the cutter handle tube. Lubricate the contact areas of the tubes with hot glue and firmly compress them with a plastic tie. Screw and tension nichrome wire to the hooks.

The cutter is ready, change the voltage and achieve high-quality cutting of foam.

Estimate the length of the pipe section. It should be equal to the sum of the length of the saw and vertical posts. Approximately 60 cm is required. Insert a spring into the end, heat the surface with a hairdryer and bend it at a right angle. The length of the segment is about 15–20 cm.

Start making a handle - wind a wire around the end, the spiral pitch is about 1 cm.

To prevent spontaneous extension of the hacksaw knee, wrap the ends with electrical tape and secure their position.

Constantly tension the wire and heat the pipe with a hairdryer. The metal will begin to dig into the pipe a little and leave deep grooves. You should have a comfortable handle that makes it easier to hold the hacksaw while working.

Using a thin abrasive disc, cut the slots at the ends for a hacksaw. Use scissors to remove excess pipe.

Insert the hacksaw blade into the holes made, fix its position using any available materials (nails, staples, engravers, etc.).

The tube gives the hacksaw sufficient tension, making it easy to work with the tool.

Using the above algorithm, prepare spiral grooves for the handle at one end of the tube. On the second, cut four slits approximately 10 mm long.

In a smaller diameter pipe, drill a hole with a diameter of 6 mm, heat the end and flatten it.

Clamp the M6 bolt in a vice, cut a piece of tube 1.5 cm long, and put it on the bolt head. Heat the plastic and use pliers to squeeze around the perimeter. You should get a lamb for tightening the elements.

Screw it into the prepared hole. To prevent the stick from being visible in the frame, bend it slightly.

Take a clamp of a suitable diameter for the pipe and paint it black.

Install it on the cut end of the large pipe, insert the small one into it and, using the thumb, firmly fix it at the required distance.

Cover the end of the handle with a plastic bottle cap, use a hot glue gun.

All that's left is to screw on the camera and go get some pictures.

Only three options for crafts are considered; in fact, there are many more of them. Don’t be afraid to experiment on your own and give unnecessary pieces of plastic pipe a second life.

What you need to prepare

In addition to pieces of plastic pipe with a diameter of 3/4 and 1/2 inches, you must have nichrome wire with a diameter of 0.3–0.5 mm and a length of 30–40 cm, a voltage transformer of 12 V or 24 V, a metal spring and a powerful household or industrial hair dryer . The diameter of the spring must allow it to fit into the nominal hole of the pipe. The pipe is cut with special scissors. Holes are made using a screwdriver with drills or stones. Electrical installation work is carried out using a flexible cable; caps from plastic bottles are used for plugs. Insulation of connections is done with heat-shrinkable sections.

Making a foam cutter

Insert a pipe bending spring into the pipe. The length of the segment is approximately 70 cm.

Use a hair dryer to evenly heat the surface of the pipe and bend it at a distance of approximately 25 cm from the end. Make a loop about 15 cm long in the upper part, press the end against the pipe.

Heat the remaining piece again and bend it at an angle of 90 degrees, you will get one arm for fixing the wire. After each bend, do not forget to pull out the spring.

Bend the second end of the tube; the length of the arm should be approximately equal to the parameters of the first. Using special scissors, trim the length of the ends of the device.

Make a hole at the turn of the handle, use a screwdriver and a nozzle with a stone. Insert two pieces of flexible cable into the hole. They must exit from two risers.

Make holes in the plastic covers. Insert a hook with an M6 thread into them, screw the nuts on the back side and firmly fix the wires.

Place the prepared plugs on the ends of the device. Solder the adapter (transformer) to the wires; protect the connection points with heat-shrinkable tubing. Glue them to the wall of the cutter handle tube. Lubricate the contact areas of the tubes with hot glue and firmly compress them with a plastic tie. Screw and tension nichrome wire to the hooks.

The cutter is ready, change the voltage and achieve high-quality cutting of foam.

Making a hacksaw

Estimate the length of the pipe section. It should be equal to the sum of the length of the saw and vertical posts. Approximately 60 cm is required. Insert a spring into the end, heat the surface with a hairdryer and bend it at a right angle. The length of the segment is about 15–20 cm.

Start making a handle - wind a wire around the end, the spiral pitch is about 1 cm.

To prevent spontaneous extension of the hacksaw knee, wrap the ends with electrical tape and secure their position.

Constantly tension the wire and heat the pipe with a hairdryer. The metal will begin to dig into the pipe a little and leave deep grooves. You should have a comfortable handle that makes it easier to hold the hacksaw while working.

Using a thin abrasive disc, cut the slots at the ends for a hacksaw. Use scissors to remove excess pipe.

Insert the hacksaw blade into the holes made, fix its position using any available materials (nails, staples, engravers, etc.).

The tube gives the hacksaw sufficient tension, making it easy to work with the tool.

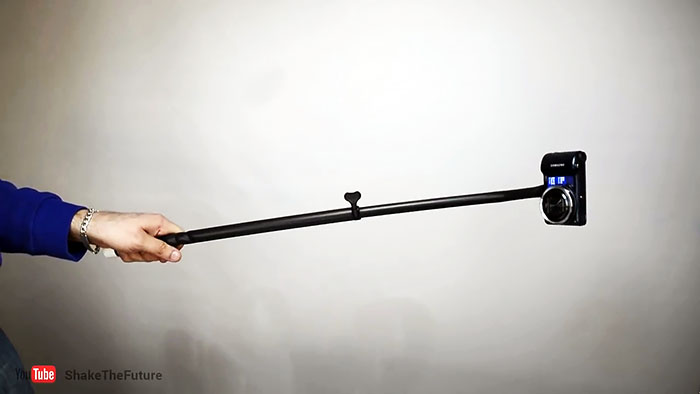

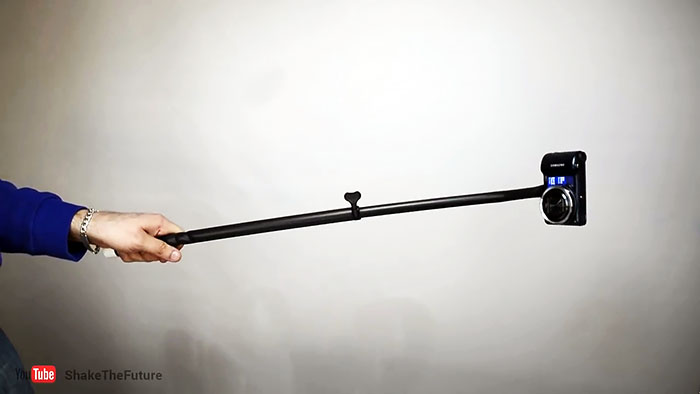

Making a selfie stick

Using the above algorithm, prepare spiral grooves for the handle at one end of the tube. On the second, cut four slits approximately 10 mm long.

In a smaller diameter pipe, drill a hole with a diameter of 6 mm, heat the end and flatten it.

Clamp the M6 bolt in a vice, cut a piece of tube 1.5 cm long, and put it on the bolt head. Heat the plastic and use pliers to squeeze around the perimeter. You should get a lamb for tightening the elements.

Screw it into the prepared hole. To prevent the stick from being visible in the frame, bend it slightly.

Take a clamp of a suitable diameter for the pipe and paint it black.

Install it on the cut end of the large pipe, insert the small one into it and, using the thumb, firmly fix it at the required distance.

Cover the end of the handle with a plastic bottle cap, use a hot glue gun.

All that's left is to screw on the camera and go get some pictures.

Conclusion

Only three options for crafts are considered; in fact, there are many more of them. Don’t be afraid to experiment on your own and give unnecessary pieces of plastic pipe a second life.

Watch the video

Similar master classes

Particularly interesting

Comments (1)