Unique DIY welding trolley with folding table

Semi-automatic welding (MIG/MAG) includes a welding arc power source, a reel and wire feeder, gas equipment with a gas cylinder, wires, a torch, hoses, etc.

If welding work is to be done outside the workshop, then moving such a bulky “equipment” will not be easy without a special cart, which we will now begin to manufacture.

It is necessary to prepare the following materials and products in advance:

When working on a cart, we cannot do without the following tools and devices: a pendulum and circular saw, an angle grinder, magnetic angles, welding, a square and tape measure, pliers, a bench vice and clamps.

Using a pendulum saw, we cut the profile rectangular pipe into blanks for the trolley base frame. We clean and cut the ends of the workpieces for welding using a grinder.

We assemble the base frame with a crossbar closer to one edge, using magnetic corners. We check the accuracy of the connection with a square and a tape measure, and only then carry out welding. We clean the welds with a grinder.

We cut the corner into blanks in pairs for two trolley shelf frames. We assemble and secure them to the workbench table with clamps, and then weld them at the corners. We also clean weld seams.

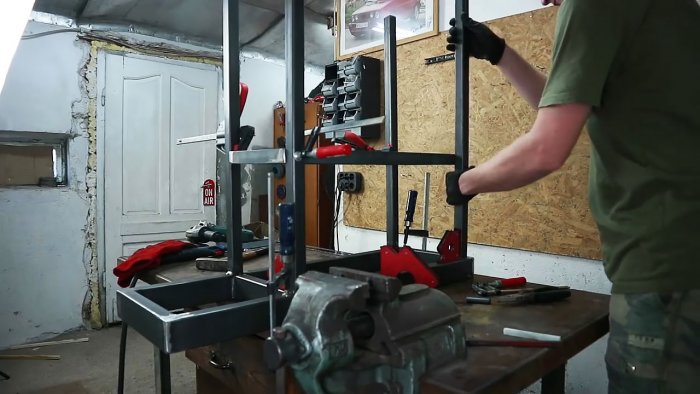

From a square pipe we cut blanks for welding cart stands - two long and two shorter. We weld them vertically to the base frame, using magnetic corners and checking the accuracy with a square.

Using clamps, we weld the frame elements of the lower shelf to the racks at a given level, then the upper one, and a jumper between the long racks along the top.

Using a circular saw, we cut a strip of the required width from the metal sheet and cut it into the required parts.

We weld the bottom of the base frame, middle and top shelves with the corresponding parts of the sheet, making cutouts in the corners.

We weld two self-aligning wheels with brakes to the base frame from the bottom at the corners.

In the rear part of the base frame, at the level of the crossbar, we weld studs - the axles of the rear wheels.To securely fasten the axles, we place square pipe sections with a notch in the middle on them and weld them to the axles and frame.

We put washers and bushings on the axles, large wheels on them and tighten them with nuts.

We weld a piece of pipe – the trolley handle – to the ends of the longitudinal elements of the upper shelf frame.

We assemble a folding table frame from rectangular pipe blanks and, after checking the accuracy of the assembly, weld the joints.

We weld brackets made of a rectangular pipe from the bottom of the top shelf, close to the posts, to which the folding table will be bolted thanks to a nut welded inside the profile.

We lightly weld the table legs to the longitudinal elements from the outside and drill through holes for the bolt, onto which we screw and weld a nut from inside the frame profile.

Using a grinder, we cut off the “pot holder” and make sure that the legs can unfold and fold freely, after which we tighten the bolt with a wrench.

We place a pre-cut sheet of metal on the frame of the folding table and tack it in several places around the perimeter to the frame.

We weld closer to the bottom of the legs and in the middle the crossbar from the corners to increase rigidity.

We weld adjustable screw supports with heels into the ends of the legs, with the help of which the table can be installed on an uneven surface.

We weld plugs onto the ends of the profiles, and limiters for the legs. Then we process it with a hand file.

From the bottom of the bolts around which the legs rotate, we drill through holes into which we insert the bolts to fix them in the working position.

We finally remove all roughness, unevenness and metal deposits from welding using a grinder and a grinding wheel.

We paint all surfaces with aerosol paint from a can and after drying, polish the surface of the folding table and cover it with metal splash spray. Then wipe it with a cloth.

We place a rubber mat at the bottom of the base compartment for the gas cylinder. To prevent the cylinder from falling during transportation, we provide a chain on top, which is permanently attached to the frame at one end, and the other is removable.

To secure wires, hoses, masks, etc. on the cart in the required places, we weld limiters, brackets, holders and loops.

We place the power source for the welding arc on the middle shelf, and hang a grinder, drill, etc. on the strip between the stands. The bottom shelf is intended for electrodes, welding equipment, etc. We hang the welder’s mask on a hook welded on top to the crossbar between the high stands.

Having laid out everything necessary for welding, we move the welding cart to the work site, brake the front wheels, unfold the table, secure the legs with bolts and start welding.

If welding work is to be done outside the workshop, then moving such a bulky “equipment” will not be easy without a special cart, which we will now begin to manufacture.

Will need

It is necessary to prepare the following materials and products in advance:

- profile pipe – rectangular and square;

- steel equal angle;

- steel sheet 3 mm thick;

- caster wheels with brake – 2 pcs.;

- large wheels – 2 pcs.;

- studs and bushings – 2 pcs.;

- pipe section;

- set of bolts, nuts and washers;

- aerosol paint in cans;

- spray against sparks and metal splashes;

- rubber mat;

- a piece of chain with a lock.

When working on a cart, we cannot do without the following tools and devices: a pendulum and circular saw, an angle grinder, magnetic angles, welding, a square and tape measure, pliers, a bench vice and clamps.

Welding cart manufacturing process

Using a pendulum saw, we cut the profile rectangular pipe into blanks for the trolley base frame. We clean and cut the ends of the workpieces for welding using a grinder.

We assemble the base frame with a crossbar closer to one edge, using magnetic corners. We check the accuracy of the connection with a square and a tape measure, and only then carry out welding. We clean the welds with a grinder.

We cut the corner into blanks in pairs for two trolley shelf frames. We assemble and secure them to the workbench table with clamps, and then weld them at the corners. We also clean weld seams.

From a square pipe we cut blanks for welding cart stands - two long and two shorter. We weld them vertically to the base frame, using magnetic corners and checking the accuracy with a square.

Using clamps, we weld the frame elements of the lower shelf to the racks at a given level, then the upper one, and a jumper between the long racks along the top.

Using a circular saw, we cut a strip of the required width from the metal sheet and cut it into the required parts.

We weld the bottom of the base frame, middle and top shelves with the corresponding parts of the sheet, making cutouts in the corners.

We weld two self-aligning wheels with brakes to the base frame from the bottom at the corners.

In the rear part of the base frame, at the level of the crossbar, we weld studs - the axles of the rear wheels.To securely fasten the axles, we place square pipe sections with a notch in the middle on them and weld them to the axles and frame.

We put washers and bushings on the axles, large wheels on them and tighten them with nuts.

We weld a piece of pipe – the trolley handle – to the ends of the longitudinal elements of the upper shelf frame.

We assemble a folding table frame from rectangular pipe blanks and, after checking the accuracy of the assembly, weld the joints.

We weld brackets made of a rectangular pipe from the bottom of the top shelf, close to the posts, to which the folding table will be bolted thanks to a nut welded inside the profile.

We lightly weld the table legs to the longitudinal elements from the outside and drill through holes for the bolt, onto which we screw and weld a nut from inside the frame profile.

Using a grinder, we cut off the “pot holder” and make sure that the legs can unfold and fold freely, after which we tighten the bolt with a wrench.

We place a pre-cut sheet of metal on the frame of the folding table and tack it in several places around the perimeter to the frame.

We weld closer to the bottom of the legs and in the middle the crossbar from the corners to increase rigidity.

We weld adjustable screw supports with heels into the ends of the legs, with the help of which the table can be installed on an uneven surface.

We weld plugs onto the ends of the profiles, and limiters for the legs. Then we process it with a hand file.

From the bottom of the bolts around which the legs rotate, we drill through holes into which we insert the bolts to fix them in the working position.

We finally remove all roughness, unevenness and metal deposits from welding using a grinder and a grinding wheel.

We paint all surfaces with aerosol paint from a can and after drying, polish the surface of the folding table and cover it with metal splash spray. Then wipe it with a cloth.

We place a rubber mat at the bottom of the base compartment for the gas cylinder. To prevent the cylinder from falling during transportation, we provide a chain on top, which is permanently attached to the frame at one end, and the other is removable.

To secure wires, hoses, masks, etc. on the cart in the required places, we weld limiters, brackets, holders and loops.

We place the power source for the welding arc on the middle shelf, and hang a grinder, drill, etc. on the strip between the stands. The bottom shelf is intended for electrodes, welding equipment, etc. We hang the welder’s mask on a hook welded on top to the crossbar between the high stands.

Having laid out everything necessary for welding, we move the welding cart to the work site, brake the front wheels, unfold the table, secure the legs with bolts and start welding.

Watch the video

Similar master classes

Particularly interesting

Comments (5)