How to make a machine vice with your own hands

A machine or drilling vice is indispensable for working with small parts in any workshop or garage. In this master class I will tell you how I made a vice for a drilling machine with my own hands. Considering that it is often necessary to clamp parts of different thicknesses, I added a small “trick” to the design to quickly change the width of the clamp, but first things first.

We cut three bars 50x50x120 mm and mark the centers on two of them, drawing two diagonals from opposite corners of the workpiece.

On the first block, along the marked center, we make a sequential through hole of 10 mm, and then coaxially with a diameter of 16 mm to a depth of 8 mm.

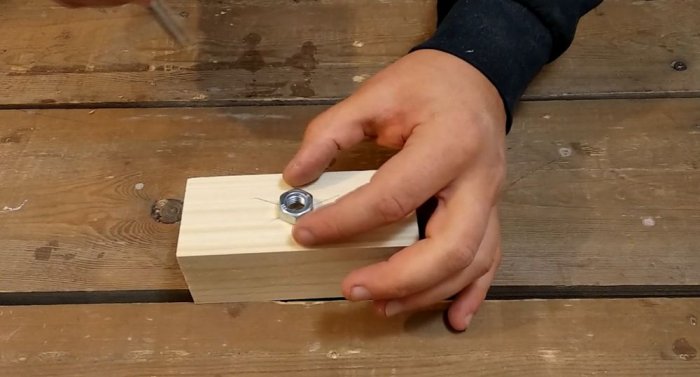

Then we look at the M10 nut.

And along the contour of the nut we mark the counter of the nut with a pencil or, as I did, with a chisel.

Working with a chisel, we make a hexagonal hole in the block to a depth equal to the depth of the second hole by 16 mm.

We press the nut into the resulting hole using a clamp, although you can simply hammer it in with a hammer.

We take the second block and, according to the markings, use a Forstner drill to make a 24 mm hole to a depth of 2 mm, then coaxially make a second hole of 12 mm and a depth of 6 mm.

Along the perimeter of the 24 mm hole evenly, after 120 degrees we drill three more holes with a diameter of 3 mm for self-tapping screws.

Next, we will assemble the base of the vice from 12 mm thick plywood - we will need pieces of 120x270 mm and two pieces of 45x270 mm. Having previously glued the parts to be connected, we fasten them with self-tapping screws along a 19 mm length of wood (pre-drill holes for the self-tapping screws with a chamfer for the countersunk head of the fastener).

Similarly, we fix the stationary jaw of the vice and the thrust part.

The stationary part of the vice is ready.

We make two cuts on the enlarged washer 8, forming a groove along the width of the hole.

On an M10 stud 250 mm long, stepping back 6 mm from the edge, we make a groove to a diameter of 8 mm with a width of about 3 mm.

We turn a handle on a lathe. In the absence of a lathe, you can plan the handle or saw off a piece from the handle for a rake or shovel (they are sold ready-made in hardware stores).

At the ends of the handle we make two holes - in one end with a diameter of 10 mm and a depth of 60 mm.

And on the other side with a diameter of 3 mm for a self-tapping screw.

We set the stud on epoxy.

The self-tapping screw on the other side is similar.

Assembling a movable sponge with a handle.

At the bottom of hole 12 we place washer 6 for goto, so that when screwed in, the pin rests against the metal and not the wood.

We screw in the pin and install the washer at 8, securing it to the movable jaw with self-tapping screws.

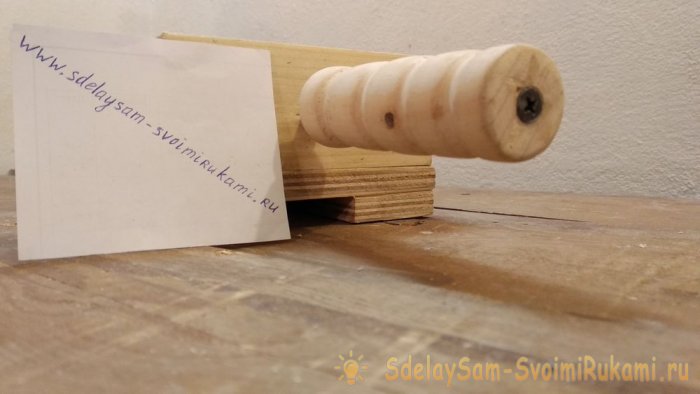

The machine vice is ready.

You can see the manufacturing and assembly process in more detail in the video:

Why do you need a self-tapping screw in the handle?

You will also learn about this in the video!

From the materials we will need:

- - timber 50x50 mm;

- - plywood 12 mm thick;

- - M10 stud and M10 nut;

- - reinforced washer 8;

- - washer 6;

- - three wood screws with a wide head;

- - self-tapping screw for wood 25 mm;

- - wood glue (I used PVA).

Step-by-step master class on making a drilling vice

We cut three bars 50x50x120 mm and mark the centers on two of them, drawing two diagonals from opposite corners of the workpiece.

On the first block, along the marked center, we make a sequential through hole of 10 mm, and then coaxially with a diameter of 16 mm to a depth of 8 mm.

Then we look at the M10 nut.

And along the contour of the nut we mark the counter of the nut with a pencil or, as I did, with a chisel.

Working with a chisel, we make a hexagonal hole in the block to a depth equal to the depth of the second hole by 16 mm.

We press the nut into the resulting hole using a clamp, although you can simply hammer it in with a hammer.

We take the second block and, according to the markings, use a Forstner drill to make a 24 mm hole to a depth of 2 mm, then coaxially make a second hole of 12 mm and a depth of 6 mm.

Along the perimeter of the 24 mm hole evenly, after 120 degrees we drill three more holes with a diameter of 3 mm for self-tapping screws.

Next, we will assemble the base of the vice from 12 mm thick plywood - we will need pieces of 120x270 mm and two pieces of 45x270 mm. Having previously glued the parts to be connected, we fasten them with self-tapping screws along a 19 mm length of wood (pre-drill holes for the self-tapping screws with a chamfer for the countersunk head of the fastener).

Similarly, we fix the stationary jaw of the vice and the thrust part.

The stationary part of the vice is ready.

We make two cuts on the enlarged washer 8, forming a groove along the width of the hole.

On an M10 stud 250 mm long, stepping back 6 mm from the edge, we make a groove to a diameter of 8 mm with a width of about 3 mm.

We turn a handle on a lathe. In the absence of a lathe, you can plan the handle or saw off a piece from the handle for a rake or shovel (they are sold ready-made in hardware stores).

At the ends of the handle we make two holes - in one end with a diameter of 10 mm and a depth of 60 mm.

And on the other side with a diameter of 3 mm for a self-tapping screw.

We set the stud on epoxy.

The self-tapping screw on the other side is similar.

Assembling a movable sponge with a handle.

At the bottom of hole 12 we place washer 6 for goto, so that when screwed in, the pin rests against the metal and not the wood.

We screw in the pin and install the washer at 8, securing it to the movable jaw with self-tapping screws.

The machine vice is ready.

Watch the video

You can see the manufacturing and assembly process in more detail in the video:

Why do you need a self-tapping screw in the handle?

You will also learn about this in the video!

Similar master classes

Particularly interesting

Comments (0)