Making a tenon socket using a drilling machine

For the strength of the connection and long service life of wooden products, such as chairs, tables, cabinets, shelves and others, tenons are used as fasteners, reliably connecting the bars to each other through holes called sockets. Making a nest for tenons in wooden products requires special equipment and knowledge of the rules of working with wood. Usually the tool is a chisel. But we will look at a simpler and more accessible way of cutting out a nest using a drilling machine.

We need to have on hand:

- Bars of the required thickness. In my case, this is a 50 mm piece about 30 cm long.

- A block with a ready-made tenon. We will prepare a hole along it.

- Vertical type drill bit.

- Ruler and pen for measuring

- Knife or sharpener to remove excess wood.

Let's get started

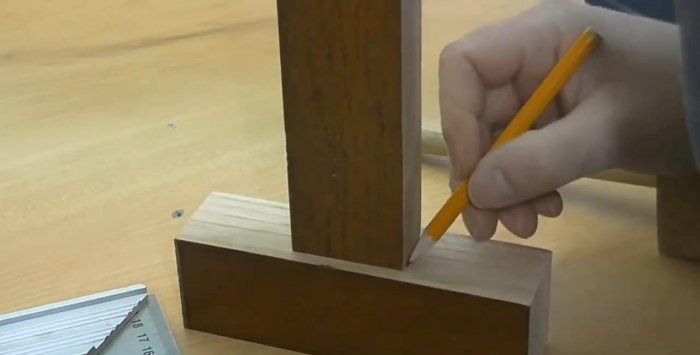

Before we start drilling, we measure the distance we need and the approximate depth of the socket.

To do this, we will use a ready-made tenon, which we apply to the block and mark the edges, width and depth of the product.

Depending on the width of the tenon, we put a drill of the required diameter of 8/10/12 mm on the machine, no less. We start drilling from the boundaries, leaving small bridges between the holes.

You won't be able to drill everything at once. At the beginning we go deeper by 1-2 cm, after making the holes we insert the drill another couple of centimeters deep, also capturing the jumpers.

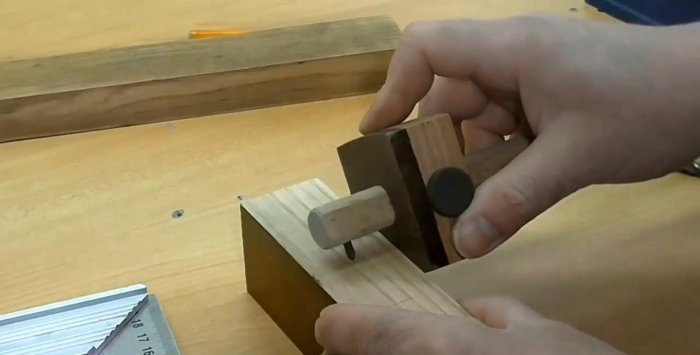

We carry out these steps until the desired size and until the marked depth is reached. We check whether the spike fits into the socket. If the nest is too large, it will not be possible to attach the spike to it.

In our case, the hole must be completed using a sharpener or a special tool for cutting wood - a chisel. We remove the corners and protrusions and re-place the tenon. This time the hole was the right size and the bars were connected to each other perpendicularly.

Advantages of this method:

- You can take a tree of any species and strength: pine, birch, oak, etc.

- Thanks to the vertical positioning, the depth and angle of the nest can be adjusted without problems.

- You can work with both small and large types of wood products.

The only inconvenience of the method is the difficulty of following the boundaries of the future nest. To do this, you need to mark with a pencil an area smaller than what is ultimately required.

Watch the video

Similar master classes

Particularly interesting

Comments (3)