How to make a high-quality pipe saddle for angled tapping

How to Make the Perfect Pipe Seat Using a Band Saw or Hacksaw

Today I will tell you how to make an almost perfect saddle when you need to connect pipes at right angles. In fact, the technology is very simple and does not require special skills and tools, all you need is a band saw (preferably) or a hand saw and a protractor.

I'm going to show it on a band cutting machine, since it's much easier to set the correct angle on it, but you can adapt to doing it on a workbench and cutting it with a cutter, hacksaw or grinder.

So, first we set the holder at an angle of 35 degrees relative to the cutting blade. Small deviations are possible here: the permissible error, which does not affect the quality of the saddle, is ± 2 degrees. When installing the pipe into the clamp, set the cut location: it should not pass through the center of the upper edge of the pipe, you should retreat approximately 5 cm from the center.

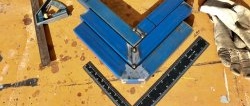

When the cut is made, the pipe is rotated 180 degrees and the same piece of pipe is cut from the opposite side.Here it is important to position the pipe accurately so that the cutting lines are strictly symmetrical.

That's all! After making the second cut, the perfectly straight saddle is ready!

If you move the cut line too far toward the center of the pipe, the top edges of the seat will be sharp and too high, which will likely interfere with the fit of the perpendicular pipe. Sharp edges can simply be cut off with a grinder or cutter so that they do not interfere.

Today I will tell you how to make an almost perfect saddle when you need to connect pipes at right angles. In fact, the technology is very simple and does not require special skills and tools, all you need is a band saw (preferably) or a hand saw and a protractor.

Preparing and cutting the seat on the pipe

I'm going to show it on a band cutting machine, since it's much easier to set the correct angle on it, but you can adapt to doing it on a workbench and cutting it with a cutter, hacksaw or grinder.

So, first we set the holder at an angle of 35 degrees relative to the cutting blade. Small deviations are possible here: the permissible error, which does not affect the quality of the saddle, is ± 2 degrees. When installing the pipe into the clamp, set the cut location: it should not pass through the center of the upper edge of the pipe, you should retreat approximately 5 cm from the center.

When the cut is made, the pipe is rotated 180 degrees and the same piece of pipe is cut from the opposite side.Here it is important to position the pipe accurately so that the cutting lines are strictly symmetrical.

That's all! After making the second cut, the perfectly straight saddle is ready!

If you move the cut line too far toward the center of the pipe, the top edges of the seat will be sharp and too high, which will likely interfere with the fit of the perpendicular pipe. Sharp edges can simply be cut off with a grinder or cutter so that they do not interfere.

Video

Similar master classes

Particularly interesting

Comments (1)