No electricity needed! A simple gas soldering iron for welding polypropylene pipes

This device is useful when welding plastic pipes where for some reason there is no electricity. Its manufacture does not require high skill, scarce materials or high costs.

Required

To make parts and assemble them into a functioning device, we will need the following materials, products and tools:

- steel pin;

- metal clamp with bolts;

- welding nozzle for plastic pipes;

- gas-burner;

- pliers;

- bench vice;

- hammer.

The procedure for manufacturing a machine for welding plastic pipes

Clamp the pin in the middle in a vice in a vertical position. We heat its upper part in the flame of a gas burner and bend the end 90 degrees using pliers.

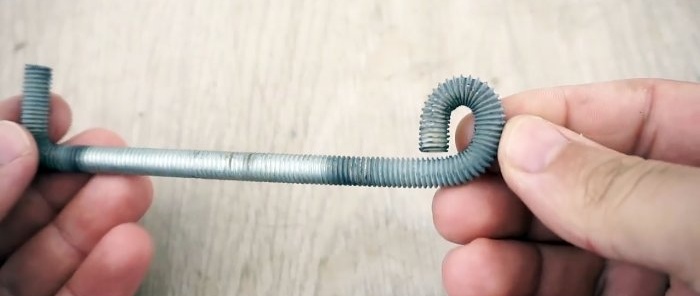

Then we turn the pin 180 degrees and, again holding it in a vice, heat the other end of the pin at a slightly longer length. Again, using pliers, bend the second end, but into a ring.

If it does not turn out perfect in one go, then periodically heating the uneven ring, we align it with pliers both in the plane of the bend and in the transverse direction.

We disassemble the steel clamp and clamp the half with the weld nut in a vice and straighten the “ears” 90 degrees so that they become a continuation of the sidewalls of the half clamp.

We screw the nut of the clamp half without the “ears” onto the thread of the end of the stud, rotated 90 degrees. Moreover, the vertical sides of the half-clamp should be oriented strictly along the stud.

Unscrew the welding nozzle for plastic pipes. We insert the bolt with one half into the ring at the other end of the stud and screw the second half of the nozzle onto the bolt on the other side of the ring and tighten it tightly with the socket head.

We put the half-clamp on the end of the gas burner nozzle and securely fasten it with a bolt and nut using a socket nut.

If the welding nozzle is shifted relative to the longitudinal axis of the gas burner flame, then the position of the nozzle is changed by heating the pin in the middle and bending it in the vertical and horizontal plane until the desired result is achieved.

To connect a plastic pipe with a coupling or fitting, we heat the welding nozzle in the flame of a gas burner, then melt the plastic elements on it and connect them together. After cooling, they will create a strong and tight connection no worse than when using a factory device.

Watch the video

Similar master classes

Particularly interesting

How to install a socket if there are short wires left

How to eliminate gaps between the chimney and slate

How to mix an ultra-reliable solution for the oven that does not give

There will be no more cracks: What to add to concrete to make it

Never buy ball valves without checking with me

New technology for floor insulation with penoplex

Comments (2)