How to make a simple awl

An ordinary awl is a fairly universal tool. They don't do any kind of work. This includes punching wood/metal, piercing soft materials such as leather, fabric or even plastic, marking on metal, etc. In many ways, the ease of use of an awl depends on the shape and size of its handle, the design options of which we propose to consider especially carefully today. And all because most of the convenient handles for an awl can be made with your own hands.

This job requires just basic hand tools, a few pieces of hardwood and a 4mm thick metal plasterboard hanger rod.

To make using hand tools you will need:

Average production time: 15 - 30 minutes.

To make using a power tool you will need:

Average execution time is 10-20 minutes.

The length of the metal rod for the awl is usually about 10 cm.

We clamp it in a vice and cut it to the size we need.

We sharpen the end with a rasp or a suitable file.

We clamp the block for the future handle in a workbench vice with its end up, and drill a hole in the center with a 4 mm drill. Depth – 3 cm. The most suitable wood for the handle is dense hardwood, such as oak, acacia, birch.

Using a wood hacksaw, we make cuts on the block, forming a cone out of it. For this job, it is best to choose a fine-toothed passing hacksaw. Then use a rasp to round the edges of the ribs.

Using sandpaper, we rub the wood, removing all burrs from its surface. The handle can now be treated with a protective coating such as organic linseed oil.

All that remains is to insert the awl into the finished hole, having previously lubricated it with strong glue, for example, two-component EAF or super glue.

For the workpiece, a round wooden block 6 cm long and 3 cm in diameter, turned on a lathe, is used.

We put it on the end, and use a drill press or drill to drill a hole with a 4 mm drill, 3 cm deep.

If possible, you can give the handle an individual relief on a lathe.

Next, we cut off a 10 cm long piece from the metal rod and sharpen it on an electric sharpener.It is worth placing a container of water near the treatment site to protect the end of the rod being treated from overheating. If you bring the metal to blue, the awl will often become dull and cause a lot of trouble in resuming sharpening.

We place the finished awl on the handle with glue and finish it with a protective coating.

Original article in English

Will need

This job requires just basic hand tools, a few pieces of hardwood and a 4mm thick metal plasterboard hanger rod.

To make using hand tools you will need:

- Wooden block of hardwood, length - 6 cm;

- Rasp, file for metal;

- Hand drill (rotary);

- Drill diameter 4 mm;

- Drywall hanger pull;

- Sandpaper;

- Hacksaw for metal;

- Wood hacksaw;

- Vise or clamps;

- Glue.

Average production time: 15 - 30 minutes.

To make using a power tool you will need:

- Wooden block of hardwood, length - 6 cm;

- Drywall hanger pull;

- Drilling machine

- Drill diameter 4 mm;

- Lathe

- Electric sharpener;

- Glue.

Average execution time is 10-20 minutes.

Option 1 - handmade

The length of the metal rod for the awl is usually about 10 cm.

We clamp it in a vice and cut it to the size we need.

We sharpen the end with a rasp or a suitable file.

We clamp the block for the future handle in a workbench vice with its end up, and drill a hole in the center with a 4 mm drill. Depth – 3 cm. The most suitable wood for the handle is dense hardwood, such as oak, acacia, birch.

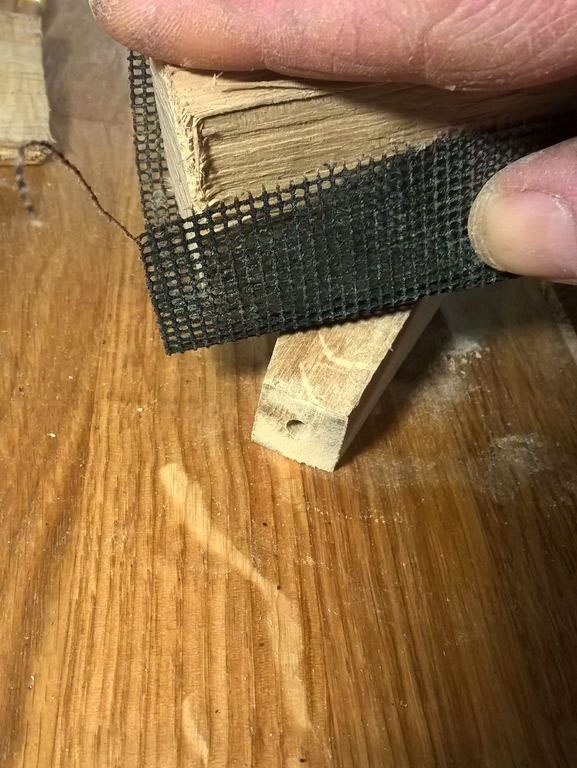

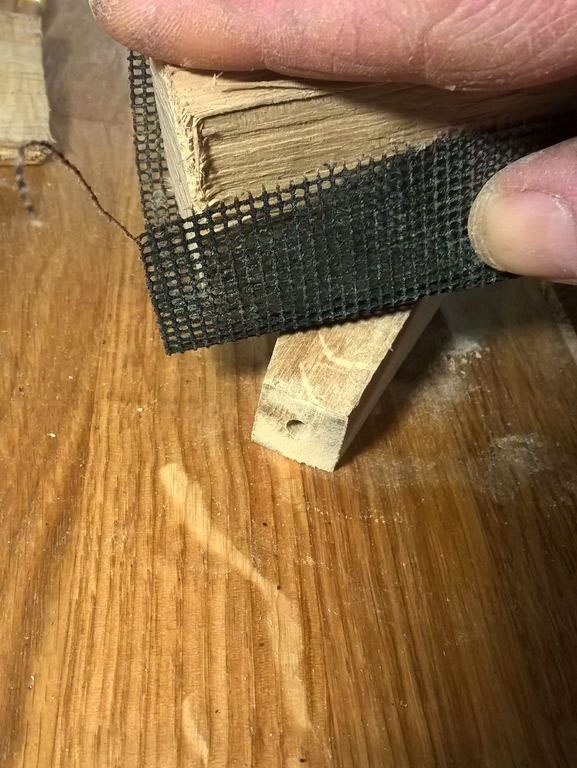

Using a wood hacksaw, we make cuts on the block, forming a cone out of it. For this job, it is best to choose a fine-toothed passing hacksaw. Then use a rasp to round the edges of the ribs.

Using sandpaper, we rub the wood, removing all burrs from its surface. The handle can now be treated with a protective coating such as organic linseed oil.

All that remains is to insert the awl into the finished hole, having previously lubricated it with strong glue, for example, two-component EAF or super glue.

We also recommend watching: Home technology for making plastic handles from recycled materials - https://home.washerhouse.com/en/5196-domashnjaja-tehnologija-izgotovlenie-plastikovyh-rukojatok-iz-vtorsyrja.html

Option 2 – manufacturing using power tools

For the workpiece, a round wooden block 6 cm long and 3 cm in diameter, turned on a lathe, is used.

We put it on the end, and use a drill press or drill to drill a hole with a 4 mm drill, 3 cm deep.

If possible, you can give the handle an individual relief on a lathe.

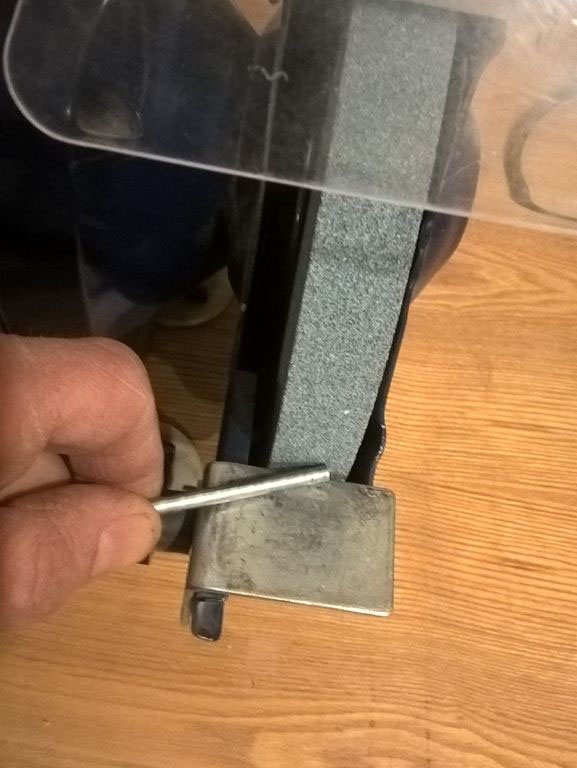

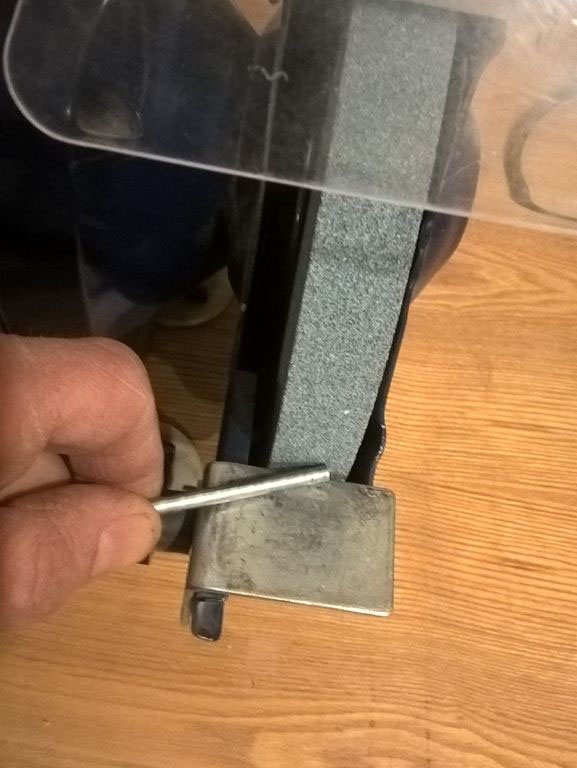

Next, we cut off a 10 cm long piece from the metal rod and sharpen it on an electric sharpener.It is worth placing a container of water near the treatment site to protect the end of the rod being treated from overheating. If you bring the metal to blue, the awl will often become dull and cause a lot of trouble in resuming sharpening.

We place the finished awl on the handle with glue and finish it with a protective coating.

Original article in English

Similar master classes

Particularly interesting

Comments (1)