How to connect tubes at any angle without welding

If you need to join 2 pipes of the same diameter at an angle without welding, you can use one trick that will solve the problem quite reliably and beautifully. This method is applicable almost everywhere, except for the assembly of load-bearing structures. They can connect pipes made of any metals.

Materials per connection:

- pipes of the same diameter;

- thick metal plate;

- M6 bolt;

- nut M6;

- M6 washers – 2 pcs.

The process of connecting pipes without welding

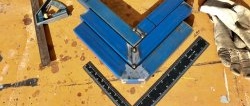

The ends of the connected pipes are cut at the desired angle.

When docking closely, there should be no gaps between them.

After this, you need to cut 2 identical blanks in the form of strips from the metal plate, the width of which will allow them to fit inside the tubes. The longer the stripes, the more reliable the connections. On an emery machine, it is necessary to make a groove half the length of each workpiece, removing the metal to the middle of the section. After this, through holes are drilled at the edge of the ground sides with a 6 mm drill, and the ends themselves are turned into a circle. Holes are made on the edges of the workpieces with a thin drill.Then the parts are twisted together with a short bolt. Washers are placed under them on both sides. The result is a hinge in the form of a square.

The made square is inserted into the tubes, and they are joined. You should set its angle so that their ends meet exactly. After this, you need to remove one tube and use a caliper to measure the distance from the edge of the remaining pipe to the hole in the edge of the square.

Based on the measurements taken, marks are placed on the tubes and they are drilled. The same drill is used as when drilling the ribs of the hinge mechanism. Here it is important to measure seven times and drill once.

The drilled tubes are installed back on the square. After this, pins are driven through their holes into the hinge holes. By blocking the square, the protruding part of the pins can be broken off or cut off. As a result, the tubes receive a fixed connection.

This connection holds the tubes quite rigidly. This fastening method is simply a godsend when it is necessary to join aluminum pipes. With this method, the joint looks perfect, even better than factory welding. The only drawback of the method is its complexity compared to welding or soldering.

Watch the video

Similar master classes

Particularly interesting

Comments (1)