How to make a power regulator for a power tool from an old vacuum cleaner

A broken vacuum cleaner is often used as a donor for valuable spare parts. One of its most useful parts for subsequent use is the speed controller. It can be dismantled, modified and used as a separate universal device to regulate various electrical equipment that is not functionally capable of this.

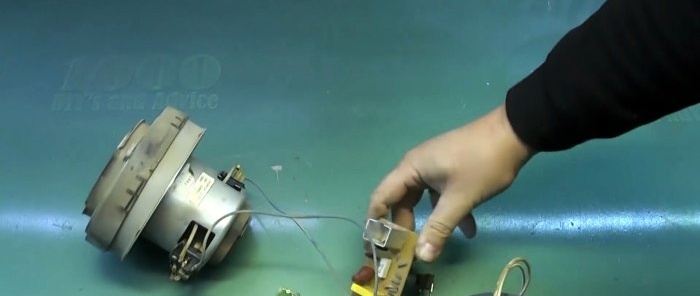

After disassembling the old vacuum cleaner, you need to remove its speed controller board.

Wires extend from it to the motor, power cable, power button and slide resistor. You should immediately note the groups of wires that will be used further. The wires from the power cable reel will be used to connect the cable to the plug. The wires from the motor are subsequently connected to the outlet.

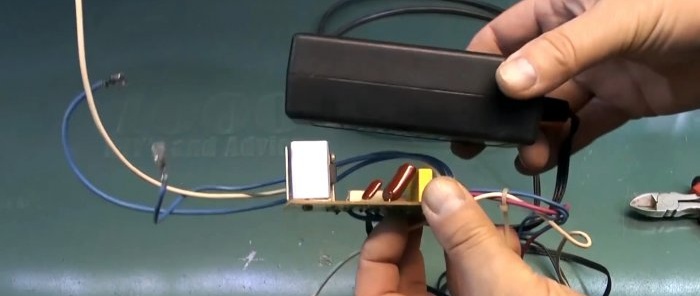

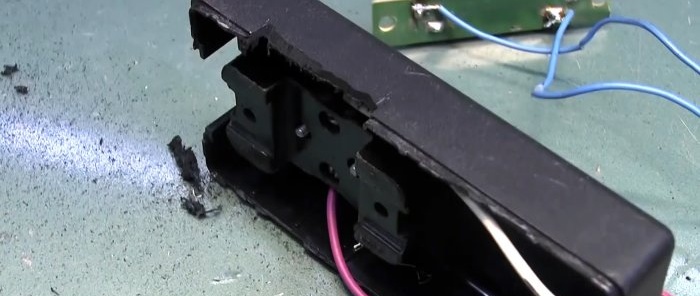

Next, you need to disassemble the case of the burnt power supply from the laptop and dismantle its contents. The socket mechanism is screwed to it from the inside.

Holes for the plug are drilled in the housing cover.

Thus, the plug of the connected device can be inserted from the outside, while the socket will be inside. The front panel of the outlet is discarded. Wires from the board, which previously went to the engine, are screwed to its mechanism.

A cutout is made on the side of the case to accommodate the slider resistor.

It is glued onto regular hot melt adhesive.

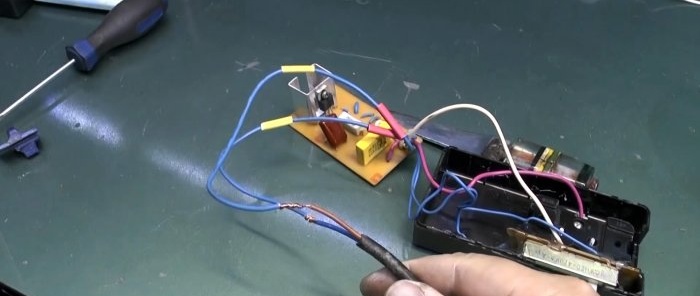

After this, you also need to connect the board to the cable with the plug.

For this, the same wires are used that were previously connected to the cable reel in the vacuum cleaner. The vacuum cleaner button, removed along with the board, is removed. Its wires are connected and insulated.

To assemble all the elements and close the case cover, you must first lay basalt wool between the socket and the board.

This is necessary so that they do not dangle or knock. You should also wrap the power cable with electrical tape before leaving the case. This will prevent it from being pulled out with a strong tug. Then the body is assembled. If it was not removable, then it can be glued back together or wrapped with electrical tape.

The resulting regulator can be used to reduce the speed of the grinder when cutting plastic. They can also adjust the speed of the drill to prevent overheating of the drills. The device is indispensable for adjusting the heating of an electric soldering iron, nichrome thread when cutting, etc.

Materials:

- vacuum cleaner speed controller;

- cable with plug;

- laptop power supply case;

- socket;

- basalt wool.

Manufacturing process of a universal regulator

After disassembling the old vacuum cleaner, you need to remove its speed controller board.

Wires extend from it to the motor, power cable, power button and slide resistor. You should immediately note the groups of wires that will be used further. The wires from the power cable reel will be used to connect the cable to the plug. The wires from the motor are subsequently connected to the outlet.

Next, you need to disassemble the case of the burnt power supply from the laptop and dismantle its contents. The socket mechanism is screwed to it from the inside.

Holes for the plug are drilled in the housing cover.

Thus, the plug of the connected device can be inserted from the outside, while the socket will be inside. The front panel of the outlet is discarded. Wires from the board, which previously went to the engine, are screwed to its mechanism.

A cutout is made on the side of the case to accommodate the slider resistor.

It is glued onto regular hot melt adhesive.

After this, you also need to connect the board to the cable with the plug.

For this, the same wires are used that were previously connected to the cable reel in the vacuum cleaner. The vacuum cleaner button, removed along with the board, is removed. Its wires are connected and insulated.

To assemble all the elements and close the case cover, you must first lay basalt wool between the socket and the board.

This is necessary so that they do not dangle or knock. You should also wrap the power cable with electrical tape before leaving the case. This will prevent it from being pulled out with a strong tug. Then the body is assembled. If it was not removable, then it can be glued back together or wrapped with electrical tape.

The resulting regulator can be used to reduce the speed of the grinder when cutting plastic. They can also adjust the speed of the drill to prevent overheating of the drills. The device is indispensable for adjusting the heating of an electric soldering iron, nichrome thread when cutting, etc.

Watch the video

Similar master classes

Particularly interesting

Cable antenna for digital TV in 5 minutes

A selection of simple and effective schemes.

Three-phase voltage from single-phase in 5 minutes

Starting a three-phase motor from a single-phase network without a capacitor

Eternal flashlight without batteries

How to make an inexpensive but very powerful LED lamp

Comments (0)