Free DIY Plastic Bottle Connection Plates

To quickly connect boards, beams and slats, perforated steel plates are used. For many structures, their rigidity is excessive, so you can use homemade plastic plates, which, unlike steel ones, are free. You can make them with your own hands in any required quantity.

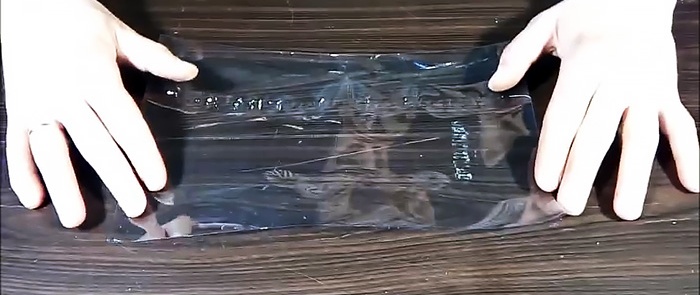

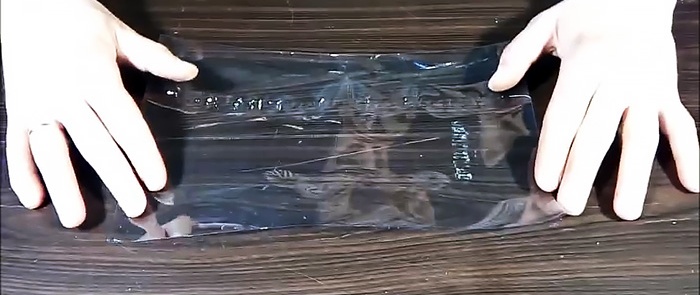

For a plastic bottle with a volume of 1-2 liters, you need to cut off the bottom and neck, after which the resulting tube is cut lengthwise.

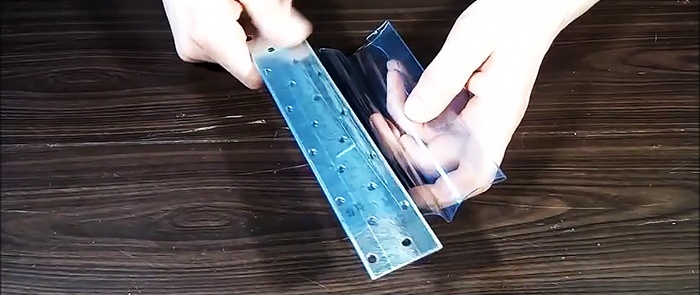

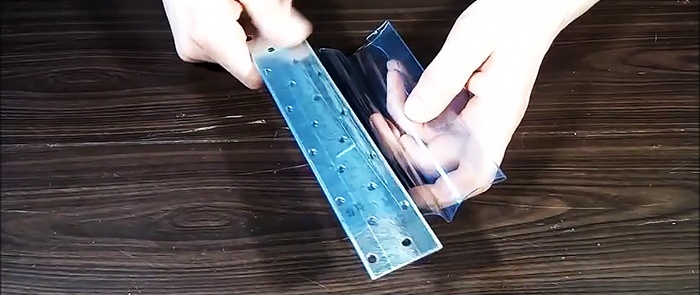

The pipe is flattened into a sheet and wound onto a steel mounting plate. You can also use a steel ruler, a carpenter's square, or a metal strip as a template.

The plate with the wound sheet is wrapped on top with PET tape 8-12 mm wide. The ribbon can be made using a bottle cutter or simply cut with scissors.The edge of the tape is not tied; it is enough to press it with your finger a little away from the sheet wound on the plate.

After this, heat shrinking is done. The easiest way is to warm up the entire surface with a hairdryer. If it is not there, then just dip the plate with the wound plastic in boiling water for a couple of seconds. You can also use open fire, but be careful not to burn the workpiece. The disadvantage of fire shrinkage is the appearance of scorch marks and soot.

After cooling, the top tape is removed. Then the plate blank itself is unwound to remove the template. Then it rewinds back.

The uneven protruding edge of the top sheet of the workpiece should be cut off along the bend with a mounting knife. You can also trim the ends of the plate. After leveling, holes are melted in it for nails or screws. To do this, it is convenient to use an electric soldering iron with a thin tip. A nail, awl, rod or wire heated over a fire will also work.

It is important to melt the holes. If you immediately pierce them with a nail or self-tapping screw, micro-tears will be created in the plate. As a result, it will withstand less load than when the holes are fused.

Homemade mounting perforated plates with the seemingly low rigidity of the bottles provide a strong and reliable connection. The parts twisted with their help, if broken, are more likely to break themselves than to break the fasteners.

Materials and tools:

- plastic bottles;

- steel mounting plate for template;

- construction hair dryer;

- mounting knife;

- electric soldering iron

Manufacturing process of mounting plates

For a plastic bottle with a volume of 1-2 liters, you need to cut off the bottom and neck, after which the resulting tube is cut lengthwise.

The pipe is flattened into a sheet and wound onto a steel mounting plate. You can also use a steel ruler, a carpenter's square, or a metal strip as a template.

The plate with the wound sheet is wrapped on top with PET tape 8-12 mm wide. The ribbon can be made using a bottle cutter or simply cut with scissors.The edge of the tape is not tied; it is enough to press it with your finger a little away from the sheet wound on the plate.

After this, heat shrinking is done. The easiest way is to warm up the entire surface with a hairdryer. If it is not there, then just dip the plate with the wound plastic in boiling water for a couple of seconds. You can also use open fire, but be careful not to burn the workpiece. The disadvantage of fire shrinkage is the appearance of scorch marks and soot.

After cooling, the top tape is removed. Then the plate blank itself is unwound to remove the template. Then it rewinds back.

The uneven protruding edge of the top sheet of the workpiece should be cut off along the bend with a mounting knife. You can also trim the ends of the plate. After leveling, holes are melted in it for nails or screws. To do this, it is convenient to use an electric soldering iron with a thin tip. A nail, awl, rod or wire heated over a fire will also work.

It is important to melt the holes. If you immediately pierce them with a nail or self-tapping screw, micro-tears will be created in the plate. As a result, it will withstand less load than when the holes are fused.

Homemade mounting perforated plates with the seemingly low rigidity of the bottles provide a strong and reliable connection. The parts twisted with their help, if broken, are more likely to break themselves than to break the fasteners.

Watch the video

Similar master classes

Particularly interesting

Comments (1)