How to make a powerful electric bike using 4 low-power motors

The topic of converting regular bicycles into electric bicycles is in increasing demand. The cost of parts for this is gradually decreasing in comparison with the prices that they had a few years ago. Therefore, for those who have long been planning to try such a project, now is the time to implement it.

Materials:

- electric motors 775 – 4 pcs -

- brackets for mounting electric motors 775 – 4 pcs -

- Sheet steel;

- toothed pulleys GT2 20 teeth – 4 pcs.;

- belt 280-GT2;

- 9-teeth sprocket with adapter for motor shaft;

- bicycle sprocket 20 teeth with ratchet;

- bicycle chain;

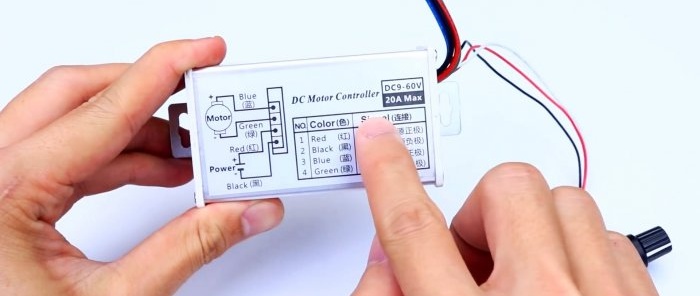

- controllers DC 9-60V 20A – 2 pcs.;

- lithium-ion batteries DC 12V 8000mAh – 2 pcs.

Bicycle conversion process

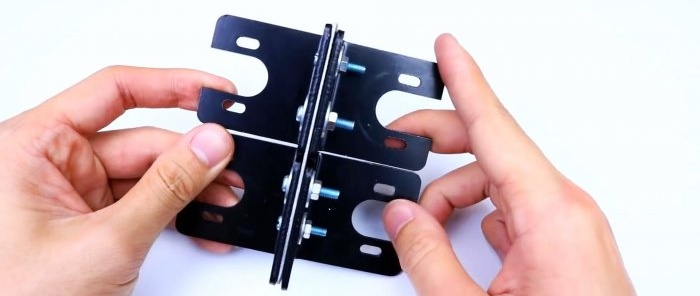

In order for the bike to have high cross-country ability when using inexpensive but powerful 775 series motors, you will need 4 of them. To connect them together you need to prepare a small plate of sheet steel. Holes are drilled in it to install 4 brackets for motors.

There are 2 fasteners installed on each side of the plate. They are all held together with screws and nuts.

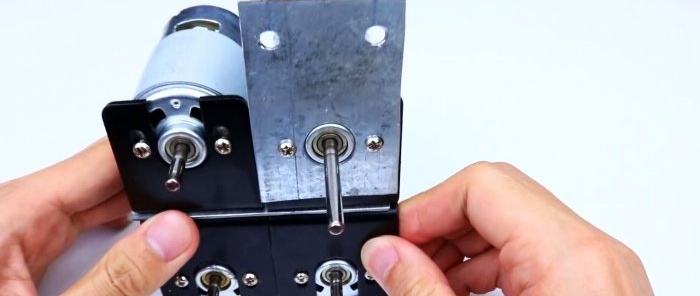

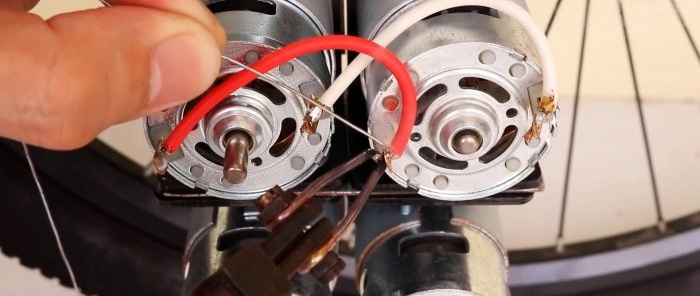

Motors are installed on the assembled block.It is important that one of them has an extended shaft.

When screwing this engine, you need to put a small plate in order to subsequently screw the block to the bicycle frame through it.

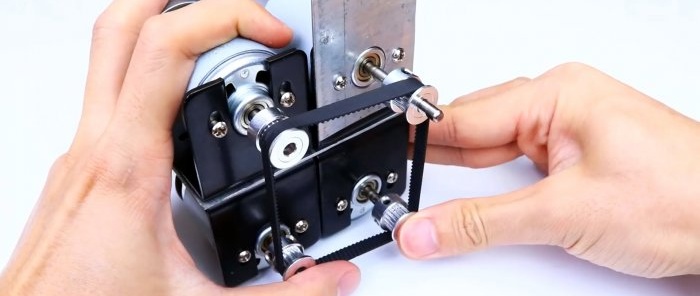

Toothed pulleys are put on and clamped onto the motor shafts. They are then connected with a belt.

An adapter with a 9-tooth sprocket is additionally installed on the protruding long shaft.

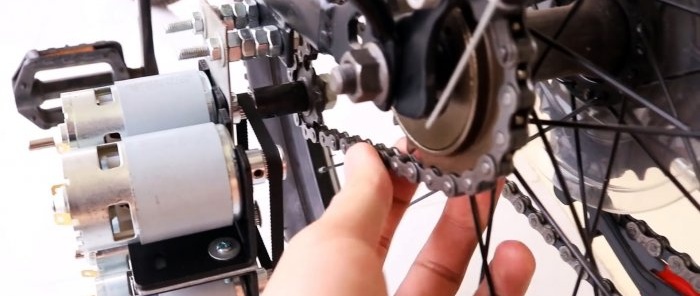

Instead of disc brakes, a 20T sprocket with a ratchet is installed on the rear wheel of the bicycle.

Then the footrest is dismantled, and a block with engines is screwed onto its mount. To do this, you need to drill holes on the plate extending from the engine bracket with a long shaft. Next, you need to connect the sprockets on the engine and the rear wheel with a chain.

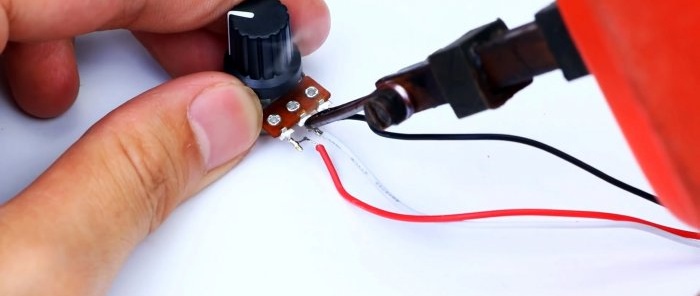

After this, you will need to solder 2 controllers to one common speed controller.

Then each controller is soldered to two motors.

A pair of motors and a controller are powered by a separate battery.

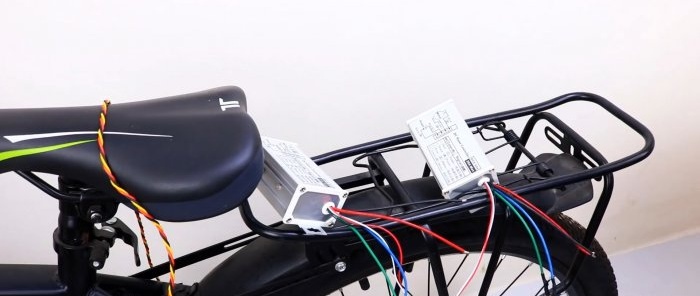

You can mount the electrical equipment on the trunk, and the speed controller on the steering wheel.

This method of alteration eliminates welding work. All equipment can be removed at any time and the bike can be completely restored to its original condition. In addition, it is possible to use the pedals and adjust the speed by regularly switching between sprockets. The only thing is that before leaving, you will need to put a rim brake on the rear wheel, instead of the dismantled disc brake.

Watch the video

Similar master classes