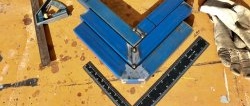

Bent bar connection at right angles

During production furniture You may need to bend the slats or bars at 90 degrees. The outer radius of such a connection is rounded, and most importantly, it does not have an open sawn end, so it looks very neat. To obtain such a bend, you need to cut a figured wedge into the workpiece, observing strict proportions.

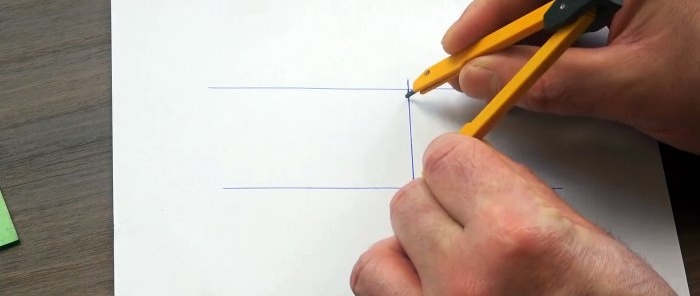

To bend the workpiece, you need to cut a wedge out of it. To maintain the dimensions with a minimum error, you will need to make a template for it. To do this, you need to trace a bent strip or bar along the paper. Next, a transverse line is drawn on the sheet at a right angle. Then you need to move the compass 3 mm narrower than the width of the workpiece and use it to draw a segment on the template.

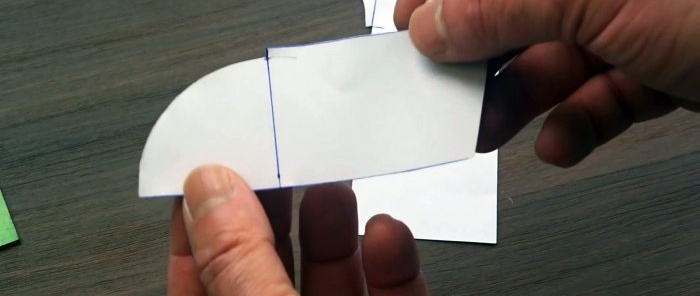

The template is cut out with scissors, applied to the workpiece and traced along the contour on the rounded side.

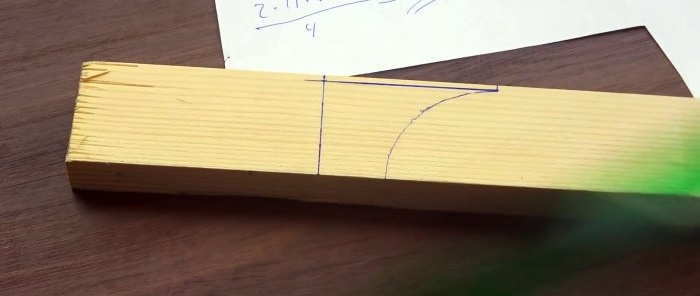

Next, you need to measure the point of the cross cut.To do this, the top of the rounded template is applied to the beginning of the step drawn on the workpiece, and it is rotated without displacement until it touches the wood with the step. A mark is placed on it, through which a transverse line is drawn.

You can double-check the correct distance of the line from the step using the formula “(2πR)/4”. The example uses a 45mm wide rail, so the fillet has a radius of 42mm. Thus, to calculate the distance to the cross cut, you need to multiply (2x3.14x42)/4=66 mm.

Having marked the transverse line, you need to step back 3 mm from its edge and from this point draw a longitudinal line to the step before the rounding. The internal space between the marks is cut out with a jigsaw.

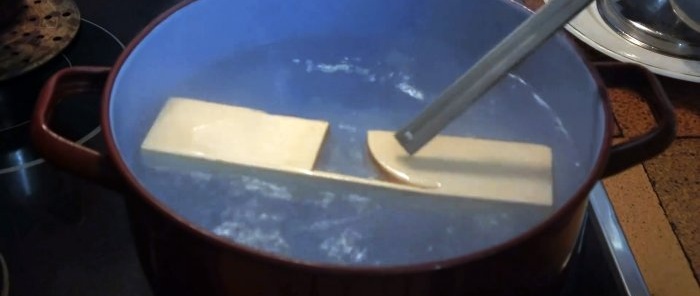

To make a bend, you need to steam the workpiece at the cutout site in boiling water. The bend is done in several approaches. After bending it a little, you should return the workpiece to the water, then bend it a little more until the workpiece bends completely. If it turns out that the width of the cut is not enough, then it needs to be expanded, and not try to forcefully press the rail.

Having stretched the fibers, it is necessary to lubricate the workpiece with glue, and bend it and clamp it with a clamp.

After drying, it is sanded with fine sandpaper to remove any glue drips. The result is a strong, neat joint that can be used when assembling chairs and other furniture. Since it does not involve the use of dowels, nails or screws, it is important to use good, proven wood glue when performing it.

What you will need:

- lath or block;

- paper;

- pencil or pen;

- clamp;

- scissors;

- compass;

- wood glue;

- jigsaw

Calculating proportions and forming a bend

To bend the workpiece, you need to cut a wedge out of it. To maintain the dimensions with a minimum error, you will need to make a template for it. To do this, you need to trace a bent strip or bar along the paper. Next, a transverse line is drawn on the sheet at a right angle. Then you need to move the compass 3 mm narrower than the width of the workpiece and use it to draw a segment on the template.

The template is cut out with scissors, applied to the workpiece and traced along the contour on the rounded side.

Next, you need to measure the point of the cross cut.To do this, the top of the rounded template is applied to the beginning of the step drawn on the workpiece, and it is rotated without displacement until it touches the wood with the step. A mark is placed on it, through which a transverse line is drawn.

You can double-check the correct distance of the line from the step using the formula “(2πR)/4”. The example uses a 45mm wide rail, so the fillet has a radius of 42mm. Thus, to calculate the distance to the cross cut, you need to multiply (2x3.14x42)/4=66 mm.

Having marked the transverse line, you need to step back 3 mm from its edge and from this point draw a longitudinal line to the step before the rounding. The internal space between the marks is cut out with a jigsaw.

To make a bend, you need to steam the workpiece at the cutout site in boiling water. The bend is done in several approaches. After bending it a little, you should return the workpiece to the water, then bend it a little more until the workpiece bends completely. If it turns out that the width of the cut is not enough, then it needs to be expanded, and not try to forcefully press the rail.

Having stretched the fibers, it is necessary to lubricate the workpiece with glue, and bend it and clamp it with a clamp.

After drying, it is sanded with fine sandpaper to remove any glue drips. The result is a strong, neat joint that can be used when assembling chairs and other furniture. Since it does not involve the use of dowels, nails or screws, it is important to use good, proven wood glue when performing it.

Watch the video

Similar master classes

Particularly interesting

Comments (0)