3 ways to weld a profile pipe at right angles without any hassle

Profile pipe is the most popular material for the manufacture of frames of various machines, fixtures and metal structures. When working with it, welding at a right angle is almost always required. This can be done in different ways, depending on whether aesthetics or speed is more important. Let's consider 3 options for welding a corner from a profile pipe.

This method can be used when it is necessary to weld rough structures that are invisible from the outside. Two pieces of pipe are simply applied to each other at right angles and scalded.

The result is a reliable connection that takes just a few minutes.

However, the end of one of the tubes remains open, which makes this option unsuitable for structures where such a joint will be visible.

This method is much more accurate. It avoids the open end of the pipe.It can be used when it is possible to make corner parts from one long pipe. To do this, a transverse line is marked on the workpiece.

Then rays are drawn from it to the left and right at 45 degrees. This is also done on the opposite wall of the pipe exactly opposite. When using a square, marking takes seconds.

After this, you need to cut out the marked part of the pipe with a grinder so that only the wall of the beginning of the rays remains. Then the pipe is bent and trimmed to a right angle.

As a result, a small gap of a couple of millimeters will remain between the walls. If you have enough experience in welding, you can weld it perfectly.

The third method is very similar to the second, but allows you to make a bend without getting that very gap that is difficult to weld neatly. To use it, you need to measure the wall thickness of the profile pipe. After this, a transverse line is drawn on the workpiece, but the rays at 45 degrees are made with an indentation from the edge by the thickness of the wall.

After this, the marked area is cut out and the pipe is bent. Thanks to the indentation made, there is no gap when bending.

As a result, even a person who has picked up welding for the first time will be able to brew accurately. This method is a little more painstaking at the preparation stage, but the result is much better aesthetically.

What you will need:

- electric welding;

- square;

- scriber or marker;

- Bulgarian;

- calipers.

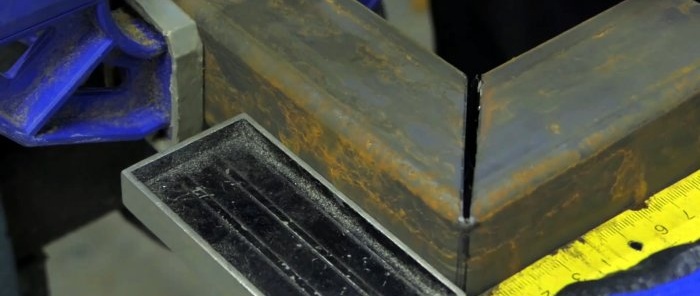

Method 1: Quick Rough Welding

This method can be used when it is necessary to weld rough structures that are invisible from the outside. Two pieces of pipe are simply applied to each other at right angles and scalded.

The result is a reliable connection that takes just a few minutes.

However, the end of one of the tubes remains open, which makes this option unsuitable for structures where such a joint will be visible.

Method 2: Washed at 45 degrees with bending

This method is much more accurate. It avoids the open end of the pipe.It can be used when it is possible to make corner parts from one long pipe. To do this, a transverse line is marked on the workpiece.

Then rays are drawn from it to the left and right at 45 degrees. This is also done on the opposite wall of the pipe exactly opposite. When using a square, marking takes seconds.

After this, you need to cut out the marked part of the pipe with a grinder so that only the wall of the beginning of the rays remains. Then the pipe is bent and trimmed to a right angle.

As a result, a small gap of a couple of millimeters will remain between the walls. If you have enough experience in welding, you can weld it perfectly.

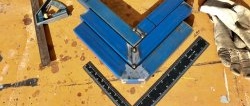

Method 3: Cut at 45 degrees, taking into account the wall thickness

The third method is very similar to the second, but allows you to make a bend without getting that very gap that is difficult to weld neatly. To use it, you need to measure the wall thickness of the profile pipe. After this, a transverse line is drawn on the workpiece, but the rays at 45 degrees are made with an indentation from the edge by the thickness of the wall.

After this, the marked area is cut out and the pipe is bent. Thanks to the indentation made, there is no gap when bending.

As a result, even a person who has picked up welding for the first time will be able to brew accurately. This method is a little more painstaking at the preparation stage, but the result is much better aesthetically.

Watch the video

Similar master classes

3 ways to weld a profile at right angles

How to connect tubes at any angle without welding

How to make a collapsible connection of profile pipes without welding

Unusual corner connection of a profile pipe

How to bend a profile pipe at a right angle in the carving style

Device for welding profiles at any angle

Particularly interesting

Comments (0)