How to restore a non-burning soldering iron tip without special paste

If used incorrectly, the non-burnable tip still burns and becomes covered with a black, persistent coating. Naturally, it becomes impossible to continue using the soldering station, since the solder does not stick. To restore such stings, they sell special pastes, which are by no means cheap. Such a purchase puts a significant dent in the pocket of the radio amateur. To avoid expenses and save time, you can use this alternative method.

Will need

- Solder.

- Rosin.

- stationery knife.

We restore the soldering iron tip with our own hands

The first step is to heat the soldering iron to 250-280 degrees Celsius. Let's immediately set the temperature on the regulator.

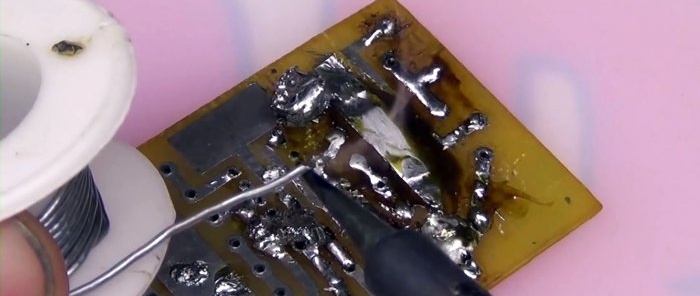

Then we take the unnecessary board, and, as far as possible, we fuse solder and rosin onto it. Of course, doing this with a non-tinned tip is a little difficult.

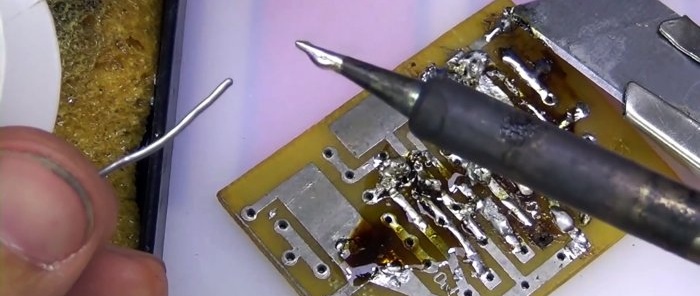

Now, having buried the tip of the tip in the solder with rosin, we begin to carefully scrape off the plaque with a stationery knife, periodically turning the soldering iron.

After a while, you will notice how the solder begins to wet the tip and it becomes tinned.

Now they can work, it’s almost like new.

The method has been time-tested and has been used on more than one soldering iron, so it works quite well and deserves your attention.

Watch the video

Similar master classes

Particularly interesting

Comments (1)