How to make mini cutters from self-tapping screws

For fine wood carving, special cutters with a narrow working part are required. They can be made by sharpening ordinary black screws. Such cutters will turn out even better than purchased budget ones, and most importantly, their edges can be given a shape that is convenient for you.

Materials:

- wood screws;

- wooden blanks for handles.

Cutting tool manufacturing process

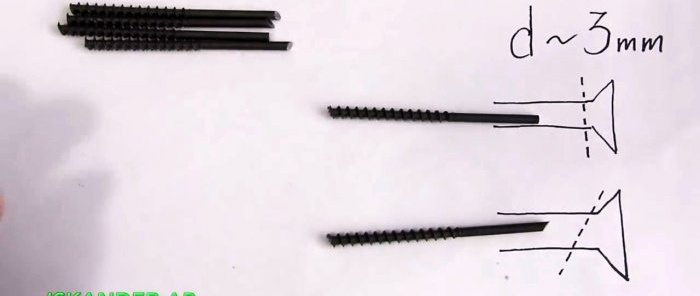

It is necessary to cut off the screw heads.

Some of the workpieces can be cut straight, some with a bevel at different angles, convenient for one or another carving technique. It is important not to overheat the metal so that it does not lose its hardening. It is better to cut screws by periodically cooling them in water.

Next they are sharpened. To do this, cut screws are screwed into a wooden holder. This is easy to do by clamping them in a screwdriver chuck. You need to sharpen on both sides, pressing them parallel to the sharpening disk, supporting them on the side with a block. The workpieces should be cooled every couple of seconds. First, the slopes are drawn, then one-sided sharpening of the cutter itself is done.

After rough sanding, final sharpening should be done using finer abrasives, or sandpaper laid on a flat surface. The cutters are sharpened by reciprocating movements with the addition of water.The grit of the paper must be reduced until the tool becomes razor-sharp.

Next, wooden handles are made.

It is best to place the cutters in them with epoxy glue rather than screw them in, as otherwise they may crack. You can also strengthen the handles by wrapping a thread around them and soaking it in glue.

To protect the cutting edge during storage, it is better to put cork caps on the tools.

Watch the video

Similar master classes

Particularly interesting

Comments (0)