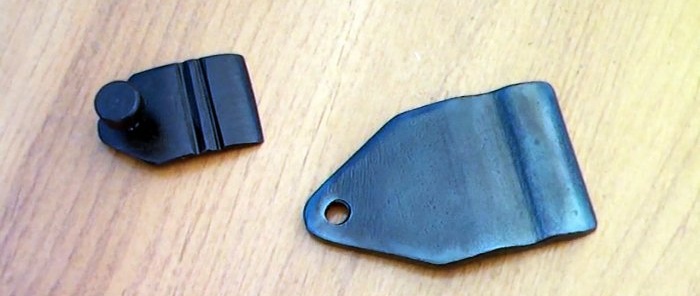

How to protect parts from corrosion using an old plane as an example

The dark oxide layer in many cases protects the steel from rust better than paint. Firstly, it wears less, and secondly, it is not afraid of heating. Burnishing or oxidation is an affordable technology that can be repeated at home.

What you will need:

- lemon acid;

- working off;

- solvent;

- gas-burner.

Steel bluing process

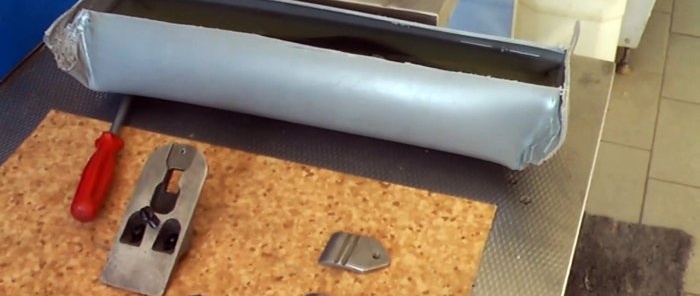

Surfaces for oxidation must be cleaned of corrosion. This is done with abrasives or simply by etching for a couple of hours in a concentrated solution of citric acid.

Before bluing, the cleaned parts are degreased. The waste is collected in a container of a suitable size. Further, the essence of the process is simple - the parts are heated one by one with a burner and dipped into used oil, as a result of which an oxide film is formed on their surface.

The subtlety of the process lies only in the heating temperature. If the part is heated red-hot, you will get a good rich blackening. The disadvantage of such heat is that as a result of heat treatment, the steel will change its properties, which is unacceptable for a cutting tool.Everything that needs to be sharpened should be heated to a gray tarnish and immediately dipped into the grind. The bluing will be less intense, but the hardness and elasticity of the steel will not change.

Watch the video

Check out this life hack on how you can quickly remove rust using a reactive method - https://home.washerhouse.com/en/7276-kak-rastvorit-rzhavchinu-za-paru-minut-reaktivnyj-sposob.html

Similar master classes

Particularly interesting

Comments (0)