How to Make a Perfect Y-Pipe Joint

If you need to weld a neat Y-shaped branch of pipes, trimming their ends causes many problems. When there is no special template available, it is almost impossible to prepare the parts correctly so that everything fits together without gaps. In fact, it’s possible to do without marking devices, you just need to know one trick.

What you will need:

- marker;

- ruler or profile pipe;

- Bulgarian;

- welding machine.

The process of marking, trimming and welding

It is necessary to measure the diameter of the pipes that will be welded.

They are then placed on a flat plane to visually indicate the welding angle.

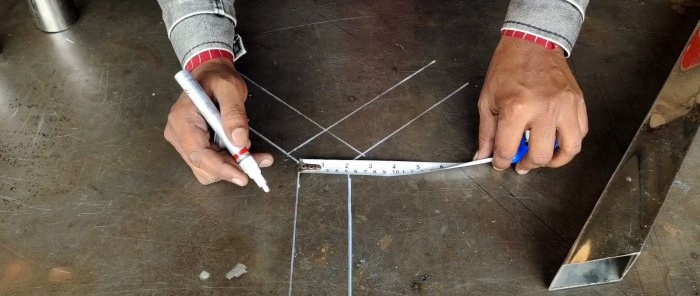

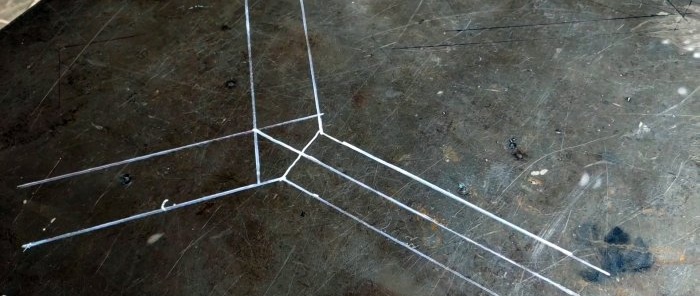

After this, you need to draw a diagram of the location of the pipes on this surface in real size. To do this, use a ruler, or a profile pipe of a similar cross-section to the one being welded.

Next on the diagram you need to draw a longitudinal line in the center of the straight pipe.

After this, the side adjacent branching tubes are alternately applied to the circuit. Looking at them from above, you need to draw cutting lines.

The marked corners of the end will need to be circled on the reverse side, and then cut off.

These 2 pipes are again laid on top of the diagram, and a third one with a straight end is tightly attached to them.

All that remains is to weld everything and clean the seam.

Watch the video

Similar master classes

Connections of three profile pipes without welding at 90 degrees in a corner

How to make a collapsible connection of profile pipes without welding

Reliable connection of profile pipes without welding or bolts

How to Make an Adjustable Jig for Perfect Pipe Trimming

Welding plastic pipes without a soldering iron

How to make a folding clothes dryer from PVC pipes

Particularly interesting

Comments (1)