How to Make an Adjustable Jig for Perfect Trimming of Pipe Welds

In order to weld pipes evenly at different angles, it is necessary to make precise trimming, which is impossible without a prepared template. Usually it is adjusted strictly to one docking parameter. The proposed template allows you to mark the end of the pipe for welding at absolutely any angle.

To make a template, you need many straight rods of steel wire. Welding electrodes stripped of coating are ideal for this.

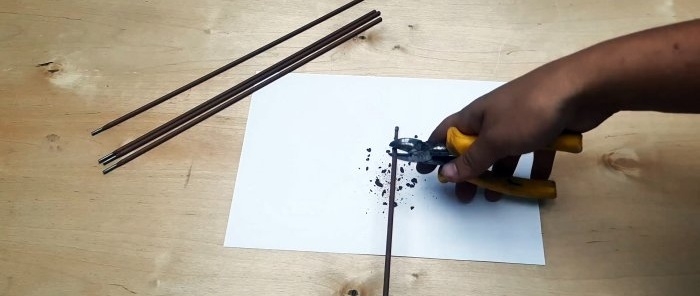

You need to cut them in half and process them from the ends so that they do not have sharp corners.

You need to wrap paper on a piece of pipe of the same diameter for which the welding template is made. Then the cut-off central part of the PET bottle is put on top and shrinked with a hairdryer. After shrinking, the resulting plastic tube is removed.

A wide ring from a bicycle inner tube is pulled onto a steel pipe. This is necessary to drag it onto the plastic tube.

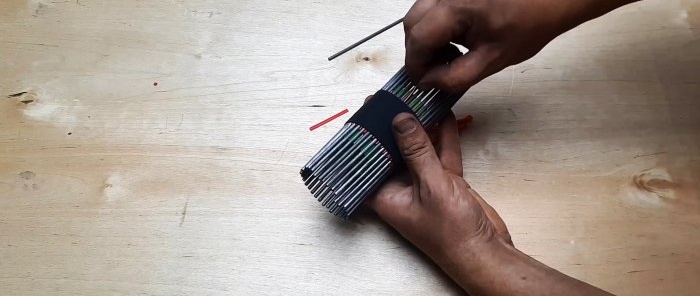

After this, steel rods are inserted under the elastic around the entire circumference. The gaps between them are filled with plastic tubes from ear sticks.

The resulting structure is placed on a steel pipe, and another middle of a plastic bottle needs to be placed on top of it with a hairdryer.

After this, the template can be placed in place and the rods can be pulled out of the body until it stops, which will allow it to take the shape of the end of the welding tube. Next, it is put on the workpiece, and markings are made on it.

The part cut in this way will fit perfectly.

See how you can make a welding clamp for welding pipes at any angle - https://home.washerhouse.com/en/7225-kak-sdelat-svarochnuju-strubcinu-pod-ljuboj-ugol-svarki.html

Materials:

- welding electrodes 2-3 mm;

- PET bottles;

- ear sticks;

- bicycle camera.

Template making process

To make a template, you need many straight rods of steel wire. Welding electrodes stripped of coating are ideal for this.

You need to cut them in half and process them from the ends so that they do not have sharp corners.

You need to wrap paper on a piece of pipe of the same diameter for which the welding template is made. Then the cut-off central part of the PET bottle is put on top and shrinked with a hairdryer. After shrinking, the resulting plastic tube is removed.

A wide ring from a bicycle inner tube is pulled onto a steel pipe. This is necessary to drag it onto the plastic tube.

After this, steel rods are inserted under the elastic around the entire circumference. The gaps between them are filled with plastic tubes from ear sticks.

The resulting structure is placed on a steel pipe, and another middle of a plastic bottle needs to be placed on top of it with a hairdryer.

After this, the template can be placed in place and the rods can be pulled out of the body until it stops, which will allow it to take the shape of the end of the welding tube. Next, it is put on the workpiece, and markings are made on it.

The part cut in this way will fit perfectly.

Watch the video

See how you can make a welding clamp for welding pipes at any angle - https://home.washerhouse.com/en/7225-kak-sdelat-svarochnuju-strubcinu-pod-ljuboj-ugol-svarki.html

Similar master classes

How to make a template for quickly cutting a profile pipe at angles

We connect 2 pipes of different diameters with a PET bottle

How to mark a pipe for precise cutting for welding elbow 90

Free corrugated pipe made from plastic bottles

Connections of three profile pipes without welding at 90 degrees in a corner

Lifehacks that will improve the quality of welding joints

Particularly interesting

Comments (1)