How to make a mini miter saw for wood, plastic and even metal

To cut small pieces of wood, plywood, plastic, aluminum and even steel, you can make a mini tabletop miter saw. It is very compact, convenient and quite quiet. This is a simple design that even a person without experience can repeat.

What you will need:

- Electric motor 895 24 V 12 thousand rpm - http://alii.pub/5siqpw

- bracket for mounting the motor - http://alii.pub/5siqru

- connector;

- gear for toothed belt 36 teeth 8 mm - http://alii.pub/5siqvc

- gear for toothed belt 16 teeth 5 mm - http://alii.pub/5siqvc

- support bearings on the feet KR-08 – 2 pcs. - http://alii.pub/5siqxo

- toothed belt 240 mm - http://alii.pub/5sir00

- shaft 8 mm - http://alii.pub/5sir16

- push button 16A;

- adapter for 8 mm shaft for saw blade - http://alii.pub/5sir52

- shaft end supports 8 mm SK8 – 4 pcs. - http://alii.pub/5sir7l

- plywood 10 mm;

- swivel spring.

Manufacturing process of a mini miter saw

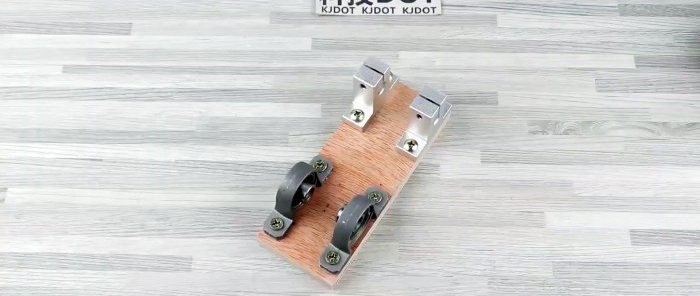

A 130x50 mm blank is cut from plywood.2 end supports and bearings are screwed to it.

On the other side you need to attach the motor bracket.

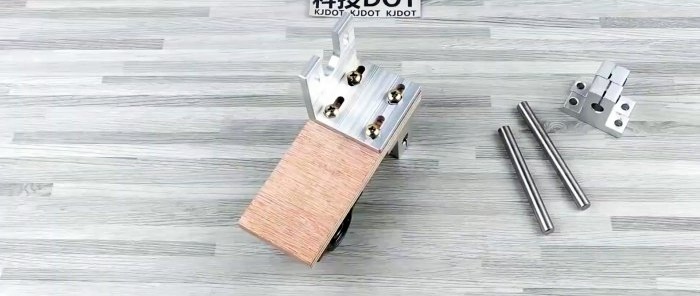

2 shafts 75 and 80 mm long are inserted into the supports and bearings. The remaining 2 supports must be placed on the rotary shaft.

Using end supports, screw the assembled rotary structure onto the plywood base. Then it needs to be spring loaded. To do this, a rotary spring is installed on the support shaft.

An adapter for the saw blade and a large gear are clamped onto the second shaft. A motor with a small gear is installed on the bracket. After this, the drive belt is tightened.

Next, the casing for the saw blade is made. To do this, its base in the form of a semicircle is cut out of plywood, and a side made of plastic strip is screwed onto it. A hole is made in the casing for the shaft, and it is screwed into its regular place.

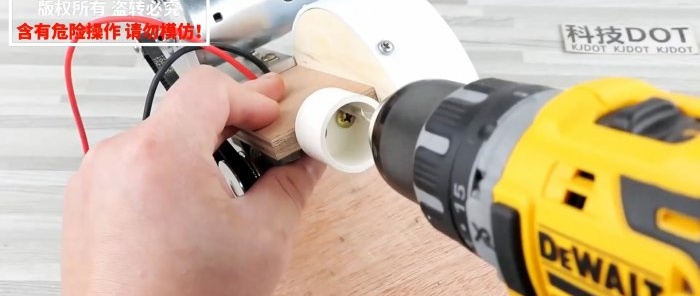

To power the motor, you need to solder the wires to the connector to its contacts.

They are routed to it through a push button without locking. The latter is placed on the saw handle. It is a piece of 20 mm plastic water pipe. To attach the handle, you can screw a pipe plug to the machine and then insert the lever into it. It is also worth choosing a larger plug to cover the motor contacts.

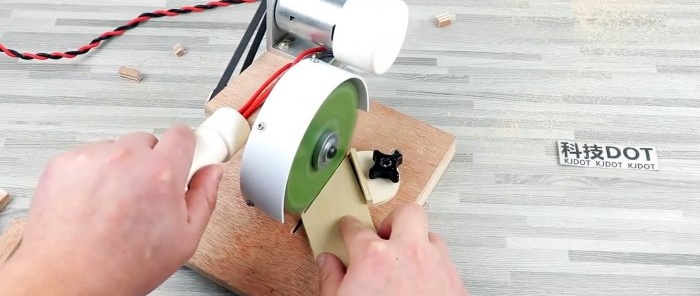

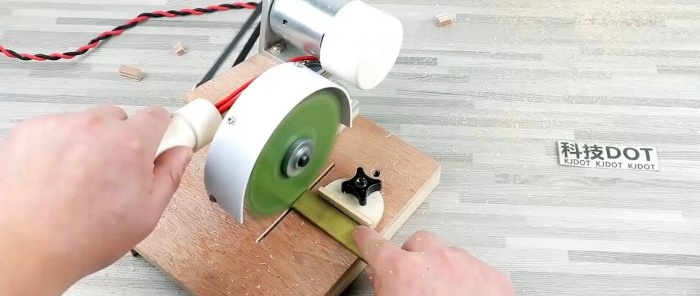

The power supply is connected to the saw connector and the saw blade is installed. You need to make a cut in its sole, and attach a parallel stop along it.

As legs, it is enough to attach 2 slats under the machine.

The miter saw is ready to go.

Excellent for sawing wood at any angle.

Also any plastic.

And if you change the disk, then the metal blanks go with a bang.

Watch the video

Similar master classes