How to Make Cheap Waterproof and Durable Paint for Concrete, Brick or Wood

To paint porous surfaces such as plaster, aerated concrete, brick walls, concrete or wood, you can use homemade paint. It is several times cheaper than purchased, but has very good wear resistance. This paint is a godsend if you need to paint, for example, a concrete floor in a workshop or garage.

What you will need:

- Gasoline – 2 l;

- solvent R-12 – 1 l;

- Styrofoam;

- color pigment for paint.

Paint preparation process

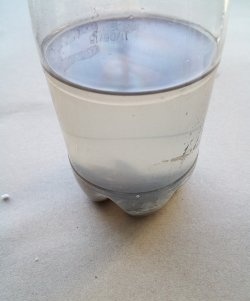

In a wide container, you can simply cut a PET bottle, pour and mix 2 liters of gasoline and 1 liter of R-12 solvent. Their volume can be changed depending on how much paint is needed, the main thing is to maintain a 2:1 ratio. Then the foam dissolves in them.

At first, the foam dissolves almost instantly, but gradually the process slows down. It collects at the bottom in the form of clots, so the solution must be stirred periodically. Polystyrene foam is added in such quantity as to achieve the consistency of varnish.The more it is, the higher the degree of paint viscosity.

The coloring pigment is added to the finished paint base, then the composition is mixed.

It is now ready to use. You can apply the paint with a roller or brush. Sometimes it needs to be stirred, as the pigment settles to the bottom and the top layer in the jar becomes lighter.

Depending on the ambient temperature, this paint dries from 15 to 40 minutes. Due to the gasoline smell, it can be used in a well-ventilated area or outdoors. The hiding power of homemade paint is worse than that of purchased paint, but the second layer compensates for this.

The coating with homemade paint is non-slippery. Although it consists of foam plastic, it is not afraid of ultraviolet radiation, so it is also suitable for covering facades. The paint completely seals cracks and pores no worse than commercial waterproofing. It also has the advantage that dust and dirt can be easily wiped off. Excess of this paint can be stored for a year or more by simply rolling it up in a glass jar with a tin lid.

Watch the video

Similar master classes

Particularly interesting