How to make a permanent tongue-and-groove joint

During assembly furniture from solid wood, such as tables, chairs, stools, tongue-and-groove joints are often used. The sawn tenon fits into the prepared socket, where it is securely held with glue. Over the years, furniture dries out and becomes loose, causing this connection to disintegrate. To prevent this from happening, it needs to be made completely non-separable, using one tricky method.

What you will need:

- Drilling machine;

- protractor;

- chisel;

- hacksaw;

- Miter saw;

- vice.

The process of manufacturing a permanent tongue-and-groove joint

The blanks for this connection are prepared in the same way as for the classic one.

However, the groove is made not with a router, but with a drilling machine. It is marked, after which it is drilled from the left with a drill inclined at 87 degrees.

To do this, you need to place something under the workpiece and align it with a protractor at a given angle.

On the other hand, the edge of the groove is drilled at an angle of 93 degrees. Then it is selected between the holes with an already directed drill at a right angle.

The groove after the drill is finished with a chisel. Then a tenon is made to the width of the entrance hole in the groove.It is made even, as usual. It can be cut out with a circular saw, a hacksaw, or both. It is rounded from the sides with a chisel.

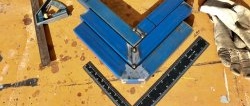

Drill the tenon on the sides as in the photo. Then it is sawed along to the holes. This is done with a hacksaw, as a circular saw will leave a cut that is too wide.

Then you need to make 2 wedges by cutting the edge of a flat piece at 93 degrees.

They are shortened to the length of the tenon and inserted into its crevices.

All that remains is to drive the tenon with the wedges into the groove.

It will burst open inside him, and he will not come back out even after years.

Watch the video

Similar master classes