How to make a jack adapter for lifting heavy loads with a low grip

It is impossible to lift a container, a metal-cutting machine or a reinforced concrete ring weighing a couple of tons without special equipment. It will also not be possible to do this with a conventional hydraulic bottle jack, since its lifting point is above the level of the load hook. A simple DIY adapter made from steel strips will help you get out of this situation.

Will need

Materials:- steel strips of different widths and thicknesses;

- hydraulic bottle jack;

- bolts and washers.

Manufacturing process of a jack adapter for lifting low-toe loads

From the steel strip we cut two blanks of the same length, the third is shorter and narrower, but all of the same thickness. The fourth blank is the same in width as the short one, but thicker, and the height is comparable to the height of the jack when not in use.

We weld two strips of equal length, with a short one between them, and aligned along one edge, along the contact lines on both sides.

We install the jack on them, aligning its side edge with the aligned sides of the three plates. We place a thick plate vertically between two long plates at the base and estimate its height.

Using a grinder, we achieve the given dimensions of a small plate with a smaller thickness than that of a vertical plate. We place it on a large plate in the center closer to one edge; two plates of the same thickness as the small one, but longer than the one lying in the center, will be placed parallel to the sides. We weld the small plate to the large one along the top and bottom edges.

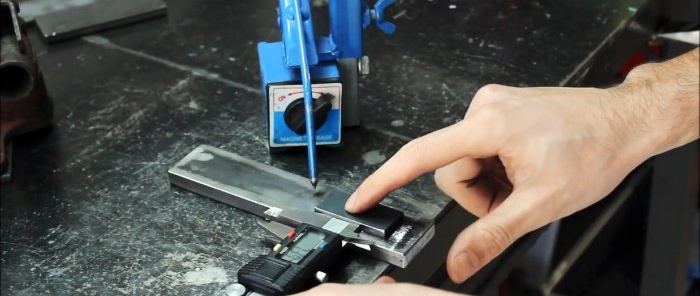

We place two plates above the jack on the base plates vertically using magnetic clamps so that the small plate welded to the large one slides easily between them, but without unnecessary gaps.

In this position, we grab the vertical plates to the base plates, and then securely scald them around the perimeter. We make cuts in the vertical plates from above and from the inside, comparing the distance between them with the width of the middle plate.

We drill a hole in the plate along the diameter of the jack's support point and weld it to a thicker and longer plate of the same width, stepping back slightly from one edge. Using a grinder, we remove chamfers from the edges of the plates.

We place the horizontal plate on top of the support point of the jack and on the end of the vertical plate, and grab the contact point, and then finally weld it.

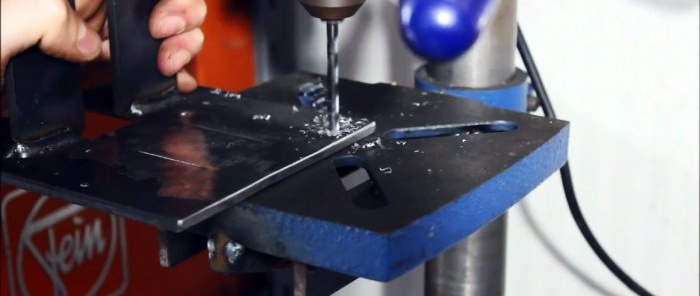

At the base of the jack we drill three through holes, and along them - counter holes in the plates with threading. We place the jack on the plates and bolt it to the base plates.

We apply a square plate to the middle plate moving between the two side plates from below from the outside and weld it securely around the entire perimeter.

We tighten the vertical and horizontal plates along the inner corner with a gusset by welding.

We bolt the transverse plate to the slider, welded to the vertical plate, through washers, having previously drilled holes and cut threads.

We drill a hole at the support point of the jack and cut the thread. We install the movable unit and fix it with a bolt to the support point of the jack.

If you close the pressure relief valve and activate the plunger pump, the moving unit will begin to rise, and with it the leg welded from below to the vertical plate of the moving unit. If you release the pressure and press on the horizontal plate, the foot will drop to the bottom position.

By placing the adapter foot under any load and actuating the jack, you can easily and reliably lift a reinforced concrete ring, technological equipment or a heavy machine.

Watch the video

Similar master classes