Homemade attachment for doubling the lifting height of a hydraulic jack

The hydraulic jack rod has an outlet of 10-20 cm, which gives a very small lifting height. If you need to significantly increase it, you can make an attachment to the jack. It is not rigidly attached to it, so the tool can be used without it if necessary.

Materials:

- Steel strip 40x6 mm;

- sheet steel 8-12 mm;

- M12 bolts and nuts.

Extension attachment manufacturing process

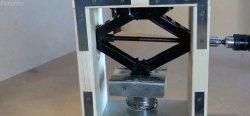

The essence of the attachment is a system of levers, due to the extension of which by the jack rod, its supporting platform receives a significantly larger range of motion than its standard one. The principle of operation of the mechanism can be understood from the cardboard model in the photo. The measurements of all levers are individual, as they depend on the parameters of the original jack. For this reason, before making the attachment, it is better to make a similar model and experiment with the length of the parts so that everything works without jamming.

Next, we cut a metal strip to make levers using cardboard templates.Each will be made from two lengths of strip to improve bending resistance.

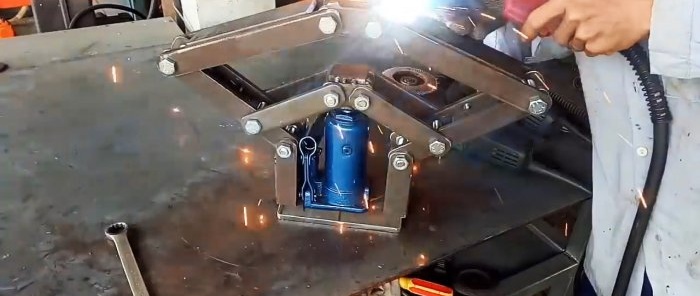

Identical workpieces are welded together at the corners and drilled.

Then you need to sharpen them to round them. As a result, the potholders will wear off and the strips will come apart again.

Based on the measurements of the jack base, the main attachments are cut out of a thick steel plate.

Eyelets from the strip are welded to it, to which the levers will be attached. For rigidity, plates are welded between them.

The first pair of arms is attached to the lugs using bolts. Each pair is welded together through a plate. Then the next levers are installed in the central holes of the previous ones.

As a result, from the last two short connecting pairs of levers we obtain the base for the platform into which the jack rod will rest. Plates are welded onto it on both sides.

Next, the longest levers are installed, and the remaining short parts for their connection. Long ones need to be made tougher by welding plates.

The working support platform of the attachment is made of the same plates as below. Only the top one needs to be cut with a grinder. This is necessary to prevent the platform from sliding.

To prevent the jack from slipping, a sleeve is welded under the support platform of the attachment into which the rod will fit. Restrictors should be welded underneath the sole. This way, the jack will be fixed under load, but if you lift the levers manually, it can be easily pulled out.

All that remains is to paint the attachment and use it for the necessary needs, where previously the height of the jack was not enough.