Inserting a pipe into a pipe: how to correctly mark and cut the joining area without special equipment. tool

It is often necessary to connect two round pipes of the same diameter at 90 degrees. Making such a connection “by eye” does not guarantee the quality and strength of the connection. But using fairly simple markup, anyone can handle this task.

Will need

- two round pipes of the same diameter;

- marker, measuring tape and compass;

- core and hammer;

- bench vice;

- Bulgarian;

- hand file;

- a piece of cardboard;

- scissors, etc.

The process of marking and cutting out the area of transverse joining of two identical round pipes

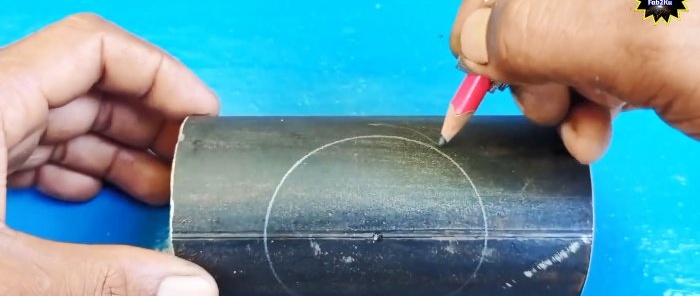

On the generatrix of one pipe, we core the center of the junction with the other pipe. We will work with pipes with an outer diameter of 60 mm. Absolutely nothing will change if they are of a different size.

We spread the legs of the compass to half the diameter of the pipe, i.e. 30 mm, which is also its radius.We place the leg of the compass at the previously marked point on the surface of the pipe and draw a circle on it.

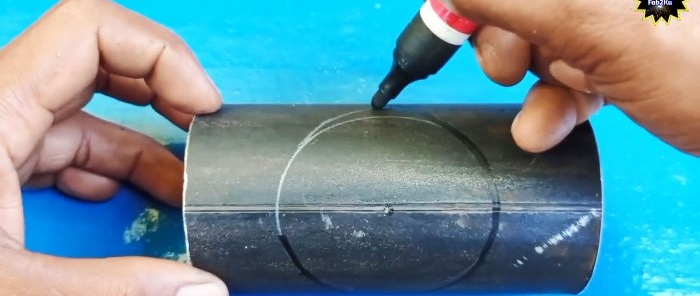

Through the intended point (the center of the circle) we draw an imaginary section perpendicular to the axis of the pipe. From the points of its intersection with the circle drawn by the compass, we set aside 5 mm.

We draw lines passing through the designated points and smoothly conjugating with the line of the circle.

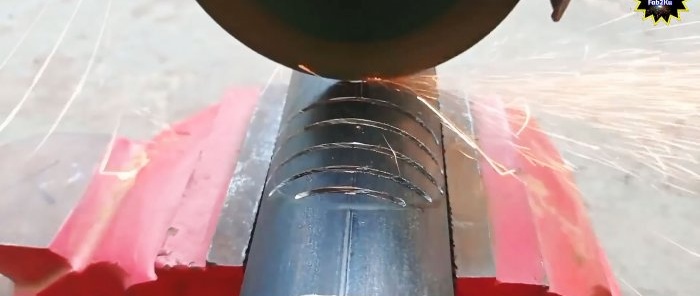

We cut out the material inside the outer closed line applied to the surface of the pipe using a grinder. We remove burrs and smooth out the remaining irregularities with a hand file.

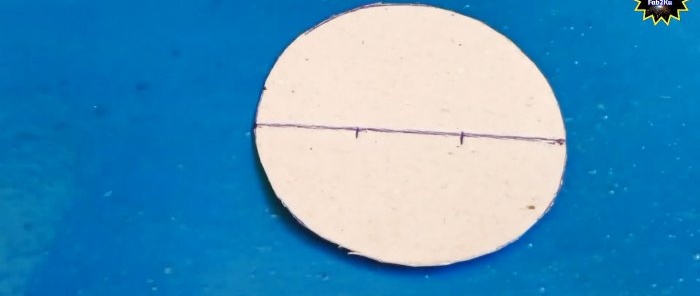

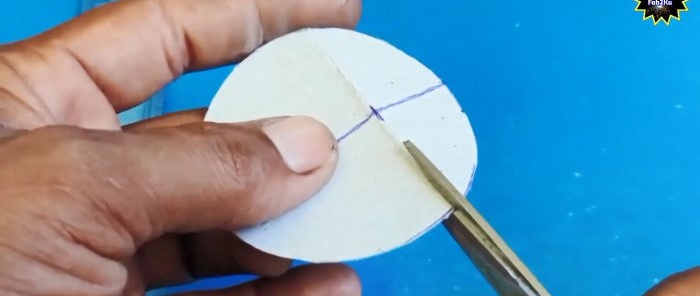

Around a section of the second pipe, mounted vertically on a sheet of thick paper or cardboard, draw a circle with a marker and cut out a circle bounded by it with scissors.

We fold the cut-out cardboard circle in half along the diameter, mark the fold line, straighten it again and lay it evenly on the end of the pipe with the fold line mark facing outward.

The intersection points of the fold line (diameter) of the circle with the cylindrical surface of the pipe are marked with a marker.

We divide the fold line of the cardboard circle into three equal parts of 20 mm each and bend one of the outer parts of the circle along a line (chord) perpendicular to the diameter and passing through the 20 mm mark of the extreme point.

We cut off the resulting segment along the chord with scissors, apply it to the outer surface of the pipe so that the chord is at the level of the end of the pipe, and its center coincides with the mark previously applied to the pipe.

Holding the cardboard segment in this position, trace the arc of the segment along the surface of the pipe with a marker. We repeat this procedure with the second point on the pipe on the opposite side.

We remove the metal of the pipe from both sides, limited by the applied lines, and smooth out sharp edges and corners.

We join the pipes in the only possible position and weld the contact lines.

Watch the video

Similar master classes