How to mark the ends of profile pipes for cutting at different angles and subsequent connection

When making structures from profile pipes, they often have to be connected at different angles. Cutting by eye leads to large errors and the joints turn out flimsy and unsightly. Below we consider a very simple method of marking, cutting along which allows you to avoid the disadvantages noted above.

Will need

- Sections of profile metal pipe;

- metal ruler;

- square;

- marker;

- grinder with cutting disc.

The process of marking the ends of profile pipes for cutting and joining

We lay out sections of profile pipe of different lengths on a flat surface so that the ends at the butt joints are connected at different angles.

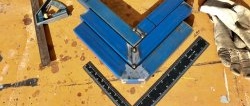

We connect the profile at right angles

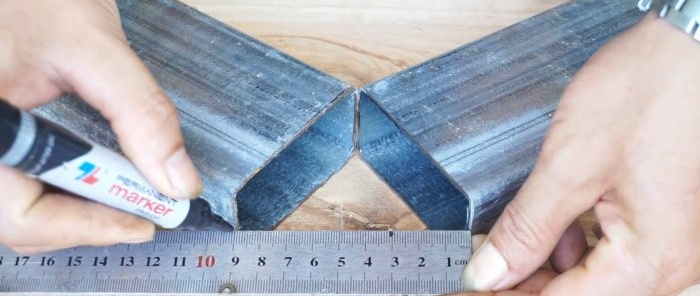

To join two identical segments at approximately right angles, which is not necessary, we measure with a ruler the most distant points on the edges of the ends in their plane.

At the point of contact of the lower edges of the segments, we place a ruler parallel to an imaginary line connecting the points of the most distant edges. We set aside half the distance of the most distant points of the faces on both sides and mark them with dots.

Using a square, we make sure that the segments have the same angle of inclination. We draw straight lines through the marked points and the points of the most distant faces until they intersect with the sides of the segments.

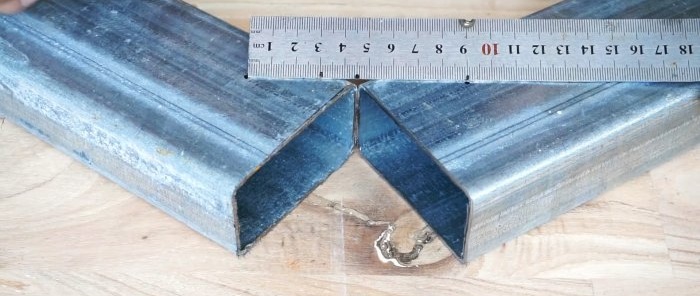

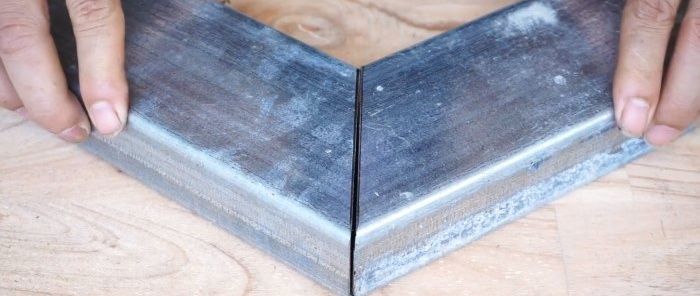

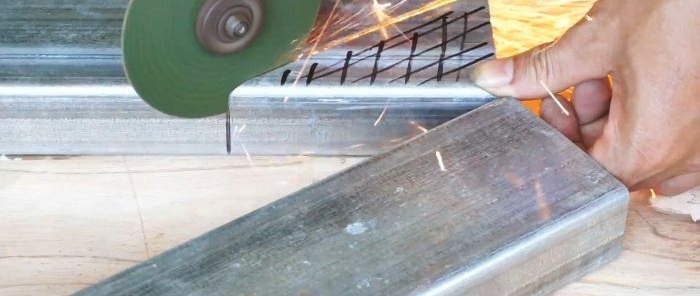

Using a grinder, we cut off the ends of the elements along the resulting line and connect them along the cutting line.

Inserting a profile at the center of a right angle

We apply the end of a short section of pipe vertically to the inside of the resulting angle and draw a straight line, as if continuing the line of contact of two identical sections of pipe.

We measure the distance from the outer point of contact of the ends of two segments of equal length to the end of the short segment. We set this distance aside on the sides of the short segment and draw a line through them, the ends of which we connect to the middle of the end.

Using the resulting inclined lines, we cut off the outer side fragments and bring the broken line of the short segment into contact with the line of the inner corner of the two inclined elements.

Joining pipes at any angle

We press the transverse segment against two inclined segments and find a point on the inclined segment, the distance from which to the transverse segment will be exactly equal to the width of the connected profile pipes.

From the resulting point along the surface of the transverse segment, draw an inclined line to the most distant external point of its end and cut off a triangular fragment along this line. We do the same at the other end of the transverse section of the pipe.

We bring the transverse pipe into contact with two inclined pipes and get two more joint assemblies.The resulting joints can then be welded or connected using plates and bolts.

Watch the video

Similar master classes