How to make a press for the production of fuel briquettes from sawdust

Tons of sawdust accumulate in carpentry shops and sawmills. This is an excellent almost free fuel, but only for specialized stoves. If you compress sawdust into briquettes, you can use them to heat with any stove, even a potbelly stove. To do this you need to make a press. Let's look at how to assemble and automate its hydraulic system.

Basic materials:

- Electric motor 4 kW;

- oil pump NSh 10;

- hydraulic cylinder;

- hydraulic distributor;

- oil tank;

- high pressure hoses.

The process of assembling a hydraulic system for pressing briquettes with your own hands

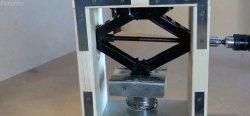

There are many drawings of the press device. The main difficulty in its manufacture is the assembly of the hydraulic pressing system. In the proposed version, its power unit is a 4 kW engine. It needs to be connected through a homemade adapter to the oil pump.

The oil pump is connected through a hydraulic distributor to a hydraulic cylinder, the rod of which directly compresses the sawdust. The system is also complemented by an oil tank. From it the supply goes to the pump, and the return flow from the hydraulic distributor also drains.Essentially, the same principle is repeated that is used on any tractor.

In this form, the mechanism operates in manual mode. The rod can only be released and retracted by switching the lever on the hydraulic distributor. This is inconvenient, since the operator must load sawdust. A simple mechanism is provided for automation. The hydraulic distributor switch is connected by a system of levers to the rod. Limit switches are assembled that switch the lever according to the click principle due to the spring. The rod, having reached the end, pushes the lever itself, and the distributor switches. This mechanism works in 2 directions.

The pressed material is poured into a hopper.

And at the end, durable fuel briquettes come out.