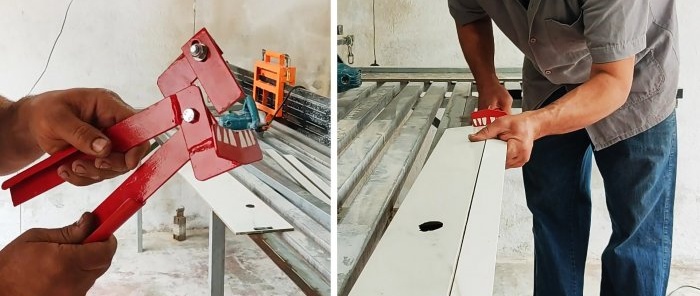

How to make devices for evenly breaking porcelain tiles along the cutting line

The home workshop does not always have at least a manual tile cutter with a cutting roller and a foot for breaking tiles. Then the cutting line is made with a glass cutter, and to break it it is necessary to use a device for breaking the tile along the cut made (pliers or wire cutters). In order not to spend money on purchasing it, you can make this tool yourself if you have at least basic skills in handling metal tools and a welding machine.

Will need

Materials:- cut porcelain tiles;

- steel strip;

- a piece of round pipe;

- bolts and nuts;

- metal paint.

The process of making nippers for breaking off tiles according to the cut made

From the steel strip we cut two long and six short pieces of the same length. Moreover, we make short sections longer than the width of the strip.In two short pieces, we drill holes in the center and weld them to the ends of the long ones to form an L-shaped permanent connection.

We weld a second pair of short pieces vertically to the ends of the short plates of the L-shaped connection. We insert a bolt into the holes of short transverse sections and make sure that the welded joints move relative to each other around the bolt, as if around an axis.

In one of the remaining short plates in the center, use a grinder to cut out a V-shaped groove with a depth of approximately 3/4 of its width. Using the groove we have made, we bend the plate in its plane. We weld the curved workpiece along the bend line transversely to the end of the vertical short plate.

We cut a piece of round steel pipe longitudinally with a grinder into two halves. Inside each of the pipe halves, we lay the long parts of the welded joints longitudinally and in the center with the outer side, aligning the ends, and weld in this position.

To the free vertical plate with a hole in the center at the end, we screw the sixth plate in the transverse direction using a bolt and nut, having previously made an oblong hole in it also in the center at the end and in the longitudinal direction.

The oblong hole allows you to adjust the tool to the thickness of the tile.

We disassemble the device and paint all its parts with spray paint. We apply designer paint to the working parts and assemble the tool, which is now completely ready for use.

We position the tool so that the cutting line is in the center of the transverse curved plate. Then, bringing the handles of the device together, we bring the end of the second plate to the porcelain stoneware from the back side and press on the handles.

A double tile stop placed on the sides of the cutting line on top and a single one on the bottom leads, when a small force is applied to the handles of the device, to break the porcelain stoneware exactly along the cut line.

Watch the video

How to glue a bathroom sink made of ceramic tiles - https://home.washerhouse.com/en/8148-kak-sdelat-umyvalnik-v-vannuju-iz-keramicheskoj-plitki.html

Similar master classes

Particularly interesting