How to repeatedly increase draft and protect an exhaust pipe from precipitation with a homemade deflector

To improve the operation of natural exhaust ventilation and protection from precipitation, a deflector is installed on it. This device increases draft by providing air outflow with the same intensity as a fan. At the same time, it does not consume electricity. You can assemble such a device with your own hands.

Materials:

- Galvanized sheet 0.4 mm;

- rivets.

Deflector manufacturing process

A strip of 900x150 mm is cut from tin.

You will also need to cut a disk with a radius of 110 mm.

It is cut to the center and rolled into a cone. Then its edges are fastened with rivets.

The same disc is used to mount the deflector to the pipe. It is sawn from the center to form triangular notches that curve outward. Here everything is calculated so as to obtain a hole for the pipe used in the hood. The remaining strip of metal around the circumference needs to be cut and pulled together with rivets to form a cone.

3 strips of 200x40 mm are cut from tin.

To increase rigidity, their longitudinal edges are bent by 10 mm and folded inward.The result is two-layer rigid strips.

The strips must be riveted to the mount under the pipe and bent. The first upward bend is made with a projection of 25 mm beyond the edge of the mount. The result should be racks 70 mm high. The rest of the part is bent inward at an angle to attach the visor in the form of a cone. The latter is installed on top with rivets.

Finally, the screen from the strip made first is fixed. It is screwed around the deflector and secured to the posts with rivets.

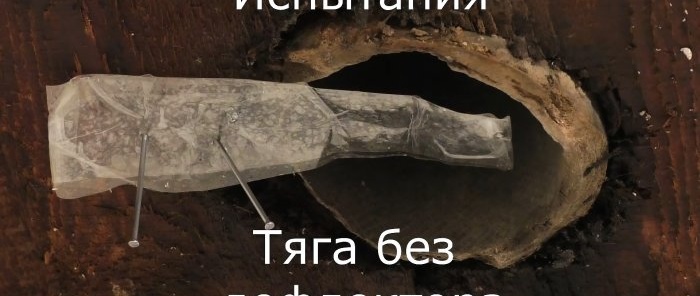

The deflector itself is tightened with a clamp at the top of the exhaust ventilation pipe.

The device operates in the presence of the slightest wind, since the thrust is enhanced by the turbulence created. If the gusts on the street are strong, then the hood literally sucks like a vacuum cleaner.