How to make a jigsaw from a manual jigsaw

The capabilities of a manual mechanical jigsaw are limited. They are slightly larger on a jigsaw. By making simple equipment from wood and plywood, you can expand the capabilities of the jigsaw and make working with it easier.

Will need

Materials:

- electric and mechanical jigsaw;

- multilayer plywood;

- different bolts, screws, screws and nuts;

- edged board;

- round rod;

- sleeve;

- extension spring, etc.

Tools: vice, grinder, welding, drilling machine, drill, circular saw, nail gun, etc.

A set of jigsaw files on Ali Express at a discount - http://alii.pub/688ntb

The manufacturing process of a jigsaw-based jigsaw

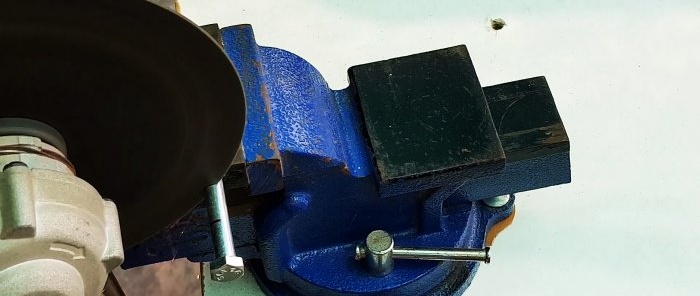

Remove the saw blade from the hand jigsaw. We also release the jigsaw file and, at its maximum reach, make a mark at the level of the sole and shorten it along it. From the bolt we cut out an adapter from one file to another.

We make a groove in it, into which we insert a shortened file and scald it.

At the other end of the adapter we also make a slot for the blade of a mechanical jigsaw.

We cut out the work table of the jigsaw from multilayer plywood.

We unscrew the support sole of the jigsaw and drill holes in the corners. We also drill holes in the work table.

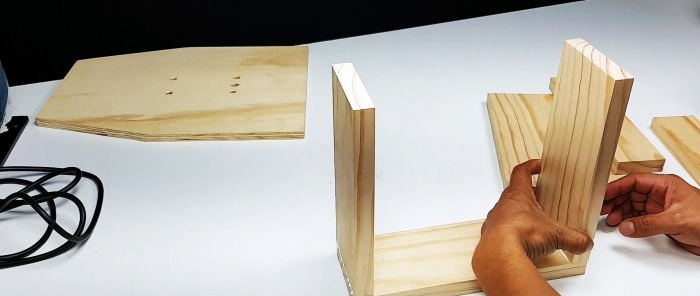

Using blanks from edged boards, we assemble equipment for the machine. Glue together two pieces of board along a large plane. We place the support sole of the jigsaw in the center of this part, drill holes for fastening and for the jigsaw blade.

Using screws, washers and nuts, we attach an appropriately oriented jigsaw to the double wooden piece.

Then we cut out blanks from the board to assemble the legs of the jigsaw. We assemble them in the required order and sequence using clamps, glue, nails and screws.

Using the holes in the workbench as templates, we drill holes in the double piece of board and insert screws of the required length into them.

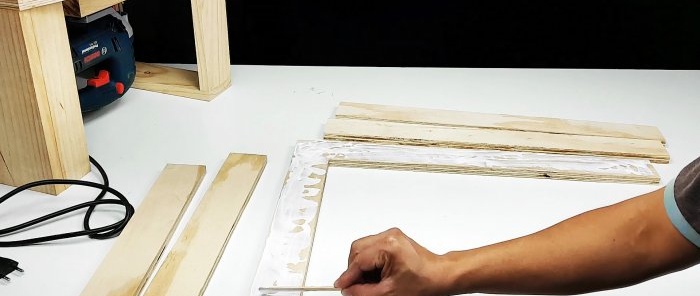

We place the double workpiece with the heads of the screws on the work table and secure it with screws from below. We place the work table with the double part down on the legs and secure it with glue and nails. We turn the structure over and attach the support sole of the jigsaw to the rods of the bolts protruding from the double workpiece. From plywood we cut out strips of the same width but different lengths. Glue them together to form an L-shaped stand. At the end of the smaller element, drill a hole with a Forstner drill.

We press the long element of the stand from the outside in the center vertically to the leg under the narrow side of the table and firmly fasten it from the inside with screws.

At one end of the steel rod we make a slot and a hook for fastening the file, and weld a washer to the other end.

Insert a bushing into the hole in the L-shaped post from above. We put a spring and a washer on the rod and insert it into the bushing.

We lower one end of the hand jigsaw blade into the hole in the table and attach it to the hook on the adapter, to which the shortened jigsaw blade is welded, and the other to the hook on the rod.

Thanks to the spring, all connections of the working body are in a tense state and do not become disconnected. Now you can easily and simply cut out shaped parts from wood and plywood.