How to solder aluminum without special flux and solder

Aluminum, due to the instantaneous formation of an oxide film on its surface upon contact with air, is practically impossible to solder. The solder just won't stick to it. It is assembled into a ball, and no matter how much you heat the part, it does not tin. We offer a clever way of how you can still solder aluminum, and without special fluxes.

What you will need:

- Motor or vegetable oil;

- soldering iron;

- solder.

Aluminum soldering process without special flux

Any oil must be applied to the aluminum surface at the soldering site. It can be motor vegetable, and even creamy. It is needed to isolate the metal from oxygen.

Then use a soldering iron tip to heat the aluminum under oil.

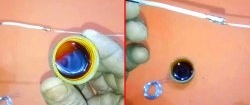

Solder is applied to the heated metal. He's going into a puddle. You need to start rubbing the molten tin into the aluminum. As a result, under the oil, the tip will erase the oxide film, and a new one will not form without oxygen. As a result, after a couple of minutes of back-and-forth movements, the solder will stick to the aluminum.

Next, the tinned aluminum part is soldered like regular copper.

With this method, tin sticks to aluminum very easily. If you try to break such a connection, nothing will work. Everything is held tight.

Flux DBL-800, which solders almost everything on AliExpress with discount - http://alii.pub/64xsle