How to solder aluminum using a nail

It turns out that you can solder a wire to any aluminum surface with regular solder, without special flux. Most DIYers are familiar with the method of soldering under a layer of machine oil. Yes, indeed, the method works, but it is not very effective. There is another, more reliable option for soldering aluminum using a nail.

Will need

- Conventional solder type "POS 61"

- Pine rosin.

- Steel nail.

How to solder aluminum with regular solder

Using a file, grind the steel nail into metal filings. It will take very little, this procedure will not take much time.

Now all components are ready for soldering.

The soldering area of the aluminum part must be cleaned with fine sandpaper.

Next, use a soldering iron to melt some rosin.

Then we apply solder to the soldering iron tip and dip it into metal filings.

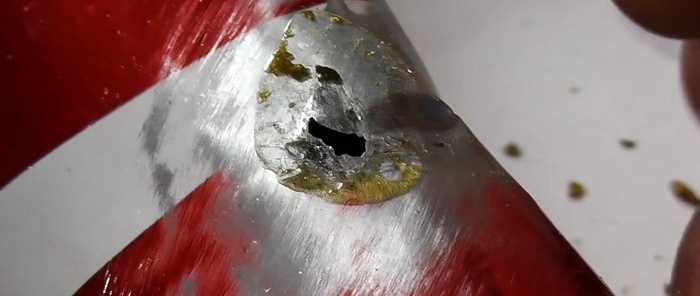

We tin the place using back-and-forth movements.

The surface wets very quickly and you can already solder the wire.

Soldering is reliable. And if you want to tear it off, it comes off with aluminum.

Which indicates a reliable connection.

Steel chips act as an abrasive.It scrapes off oxide and solder in no time, under a layer of flux, and easily sticks to bare metal.

Watch the video

The easiest way to solder aluminum wires without special fluxes is https://home.washerhouse.com/en/7341-naiprostejshij-sposob-spajat-aljuminievye-provoda-bez-specialnyh-fljusov.html