5 life hacks for repairing broken home equipment and more

Almost anything that is broken can be fixed. Moreover, often a repaired item will be no less reliable than a new one. Let's look at 5 life hacks, knowing which you will be able to repair household equipment, and also perform other household tasks efficiently.

1. Repair the fastening of the mop or brush handle with a clamp

If your mop or broom handle mount is cracked, it can be repaired. To do this, you need to tighten it with a regular worm clamp.

After this, the handle will be screwed securely again.

2. Repair the fastening of the mop or brush handle with glue and thread

Also, such a malfunction can be repaired by tightly winding a thread around the fastener, having previously glued its end. After this, you need to soak the winding with superglue.

The resulting composite material will hold no less securely than a clamp.

3. Change the fastening of the scraper handle

If the fastener breaks off at all, then it is necessary to clean the area under it, removing the protruding plastic.

Then the neck and cap are cut off from the PET bottle. The neck is put on the handle of the scraper and added with nails.

The lid must be screwed onto the plane prepared on the scraper using three self-tapping screws.

Be sure to drill with a thin drill before doing this. If you immediately twist the screw, the plastic may burst. After that, screw the handle with the bottle thread on the end.

High-quality and durable drills on AliExpress at a discount - http://alii.pub/5zwmxz

4. Homemade countersink from a drill

To prevent the heads of the screws from sticking out when tightening, countersinking is done. You can make a countersink for this yourself. Simply grind the drill as shown in the photo, leaving a sharp edge only in the center.

After this, the drill will countersink the holes, but will not be able to go deeper into the material. The head of the self-tapping screw that is screwed in after it does not stick out.

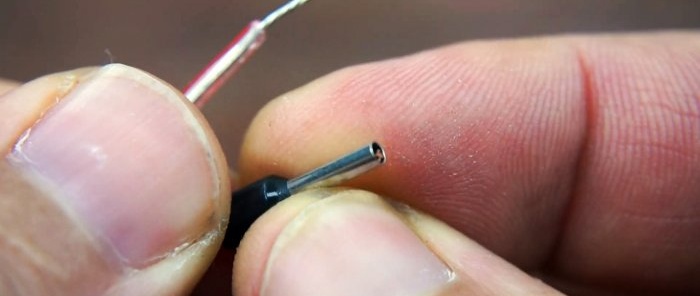

5. Connecting wires with a terminal block

If you clamp a stranded wire in a terminal block, then such a connection will not be reliable. The screw will simply crush the core, and it will easily break off if slightly loosened.

To avoid this, you must first crimp the tip onto the end of the core. If you already insert it into the block, then there will be no such problem.