How to make a garden shredder

After cleaning, there are a lot of branches left in the garden. Having a chopper, they can be crushed into small chips. This tool is extremely useful, as it allows you to keep the area clean, and at the same time make excellent mulch for the beds. You can do it yourself.

Materials:

- Planing shaft;

- electric motor 3 kW or more;

- profile pipes 20x20;

- channel;

- corner 50x50 mm;

- sheet steel 2 mm, 5 mm;

- drive belt;

- foot switch;

- bolts, nuts.

Shredder manufacturing process

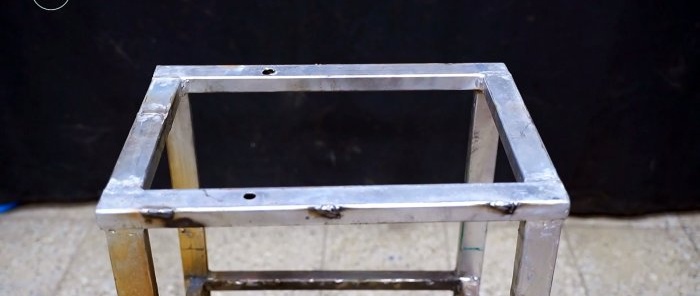

The shredder frame is assembled from a profile pipe in the form of a table. Its dimensions depend on the available motor, as well as the jointing shaft.

The frame is drilled and a shaft with knives from a jointing machine is screwed onto it.

Then, from the channel and angle, you need to weld a guide for feeding branches. It should be powerful so as not to bend under load. Grooves are cut out at the corners so that the gap between it and the guide can be adjusted. Then it is screwed onto the frame.

A pulley is put on the shaft. Then the engine is screwed onto the frame. To do this, you will have to weld jumpers from the strip. A drive belt is tensioned between the motor shaft and the jointer.Its tension will be adjusted using the standard engine mounting holes.

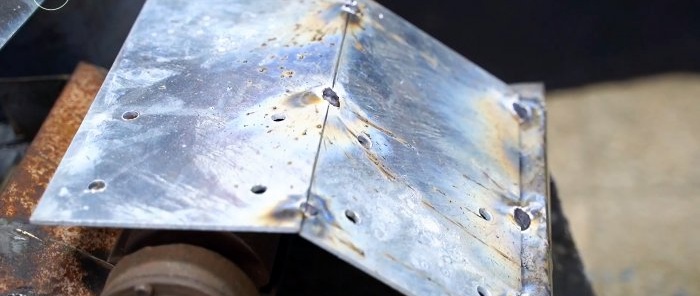

Next you need to deal with the shredder body kit. The wood chip collection funnel is made from thin sheet steel. To keep it securely, it is better to strengthen it with side gussets and a thin tube.

To ensure safety, a broken sheet steel protective screen is welded over the shaft with knives. The loading neck is also made.

Then you need to start connecting the motor. It is better to lay the wire to it through the pedal so that the shredder starts only when it is pressed.