How to make TIG welding from a regular inverter

The purchase of modern TIG welding equipment, the capabilities of which significantly exceed the functionality of manual electric arc welding (MMA), will make a noticeable gap in the family budget. But you can assemble TIG welding yourself and you don’t need any special knowledge, skills or experience.

Will need

Materials:

- gas burner of the “Pencil” type;

- round head bolt and nut;

- FUM tape;

- rubber tube with fitting and two clamps;

- Super glue;

- EKF heat shrink box tube;

- inverter with non-consumable electrode;

- gas cylinder, etc.

Tools: long-nose pliers, lathe, drills, taps, wrenches, hair dryers, hacksaws, round nose pliers, etc.

Welding electrodes for general purposes on AliExpress at a discount - http://alii.pub/606j2h

The manufacturing process of TIG welding based on a gas pencil and a household inverter

Using long-nose pliers, unscrew the filling valve from the gas burner body. We clamp the body of the gas burner in the spindle of the lathe, drill out the central hole to a certain depth and cut the thread with a tap.

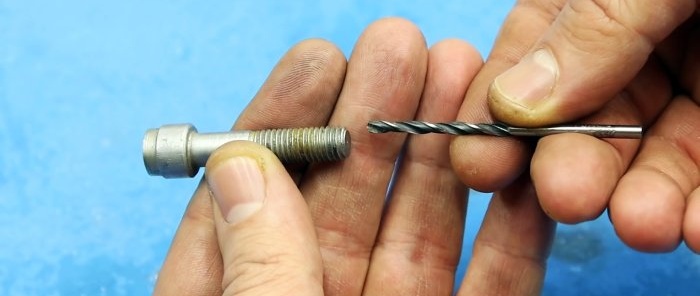

In a bolt with a round head, we drill a central through longitudinal hole, grind the head and cut three circular grooves.

From the hole in the gas burner body, we remove a strip of foam rubber, as well as metal shavings and small particles that could get inside when drilling the hole and cutting threads.

We screw a nut onto the bolt with the central hole, wind FUM tape onto the thread, screw it into the threaded hole in the gas burner body and tighten the nut with an open-end wrench.

We put a rubber hose with two wire clamps on the round head of the bolt screwed into the body of the gas burner, pre-lubricated with superglue.

We close the joint of the bolt with the body of the gas burner with a heat-shrinkable box-shaped tube and shrink it using a household or construction hair dryer.

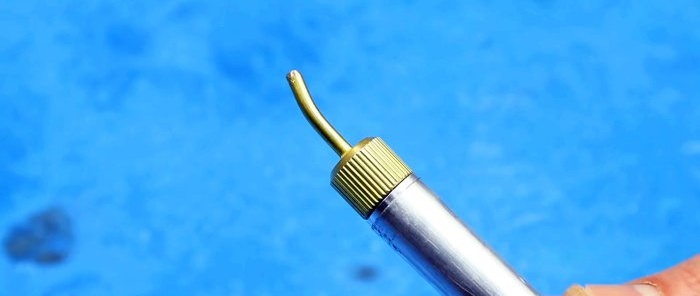

Using pliers, unscrew the nozzle with the gas supply regulator from the thread of the tube, cut off the threaded part of the tube with a hacksaw, remove the chamfer and bend the end to the side using pliers.

We connect the modernized body of a pencil-type gas burner with a piece of hose attached to it with the body of a non-consumable electrode (read how to make it HERE) using tape in several places. Moreover, the end of the gas tube should be directed towards the end of the non-consumable electrode.

We connect the ground wire to the positive terminal of the inverter, and the electrode wire to the negative terminal. We supply argon or inert gas through a gas burner and voltage to the non-consumable electrode.

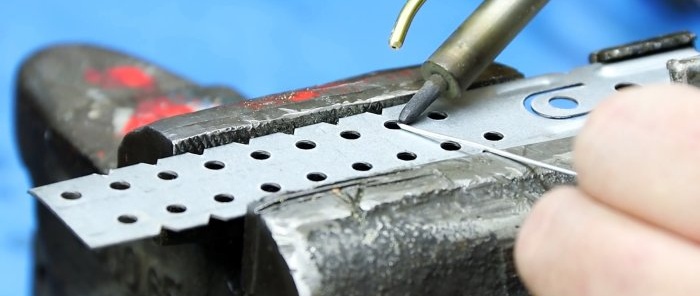

We excite an electric arc and use a filler wire to weld holes in the metal plate.

Multi-electrode, iridium and any other spark plugs on Ali Express at a discount - http://alii.pub/69bzlo

Watch the video

3 ways to weld metals with a graphite rod from a AA battery - https://home.washerhouse.com/en/8654-3-sposoba-svarki-metallov-grafitovym-sterzhnem-iz-palchikovoj-batarejki.html

Similar master classes