How to make an ax with two blades for quickly chopping wood

An ordinary household ax with one handle and one blade is intended for various tasks, in particular, for chopping firewood. However, the process is slow and labor-intensive. If you attach a second one transversely to one blade of the ax head, the process of chopping wood will speed up almost twice.

Will need

Materials:

- 2 household axes;

- wooden ax;

- round wedges for an axe;

- round head screw.

Tools: different hammers, ruler, scriber, marker, grinder, vice, core, drilling machine, band saw, tap, grinder, sharpening machine.

The process of making an ax with two transverse blades

Using a screwdriver, rocking the ax handle and hammers, remove the ax handle from the eye.

We draw a transverse line along the border of the canvas and its cheeks and cut the ax head into two parts.

Long-lasting discs for angle grinders on AliExpress at a discount - http://alii.pub/61bjly

We place the ax without cheeks on the canvas, marking the side edge of the canvas, which ends with the heel. We place the whole ax head on the canvas, turning it 180 degrees and aligning the blades.We draw a line along the lower canvas, repeating the side profile of the upper ax head. We carry out through cutting with a grinder along a line on the canvas.

On the whole ax head, from the side of the edge ending with the nose, at the border of the canvas and the cheek, we draw the contours of a rectangular cutout with a marker and use a grinder to make it approximately 2/3 of the width of the canvas in this place.

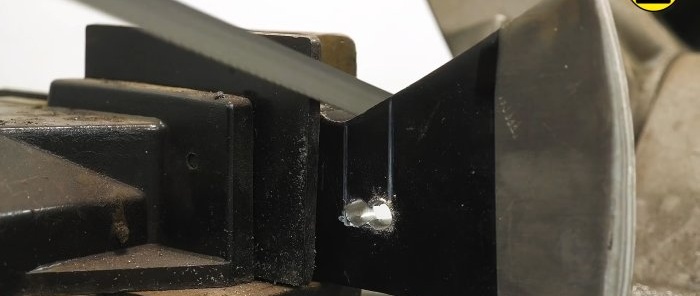

On the border of the future slot, we mark two points in the corners with a core and drill two holes. Then we make cuts from the edge of the blade to the outer edges of the holes with a band saw and knock out part of the cut blade with a hammer.

We lay the canvas without cheeks on a flat surface, install the whole ax head vertically in its center in a direction transverse to the blade and trace its outline with a marker on the canvas without cheeks.

We close these two lines with a transverse line parallel to the butt of the axe. Also, at the corners of the drawn contour, we mark two points with a core and drill two holes. From the blade in the direction of the holes, we make the slot markings. We remove the cut fragment and process all the slots with a file.

We place the ax blade without cheeks in the slot of another ax and mark a point for drilling a hole, which we do on a drilling machine. Then, using the resulting hole as a template, we drill a hole in the second ax and cut a thread in it with a tap.

High-quality and durable drills on AliExpress at a discount - http://alii.pub/5zwmxz

We cut off the part from the ax that was in the eye and form a new landing area using a grinder. We place the ax head with a transverse slot on the ax handle and wedge it with two round wedges.

We sharpen the blades on a sharpening machine and first split the lumps using an ax with one solid blade. As a rule, lumps from one blow split into no more than two parts.

Now we install the blade of the ax without cheeks into the slot of the ax with a solid blade and secure it there with a screw. The result is an ax with two blades arranged transversely, from one blow of which the log shatters into four parts.

Welding electrodes for general purposes on AliExpress at a discount - http://alii.pub/606j2h