How to make an ultra-compact and economical diesel stove

A gas and electric stove can be successfully replaced by a diesel fuel stove made from scrap materials. This does not require special knowledge or skills.

Will need

Materials:

- round, profile rectangular and square pipes;

- metal strip;

- periodic fittings;

- metal paint;

- nut and compression spring;

- tap with fittings;

- IV kit;

- container with flammable liquid, etc.

High-quality and durable drills on AliExpress at a discount - http://alii.pub/5zwmxz

Tools: drill, hammer, measuring and marking tools, hacksaw, welding, drilling machine, etc.

The process of making a super-economical diesel stove

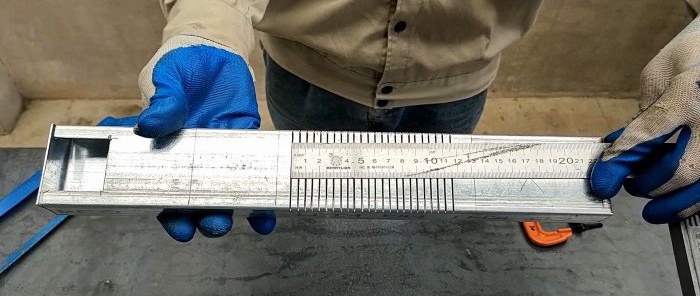

We cut a piece 45.5 cm long from a profile rectangular pipe 3x6 cm. Stepping back from the edges by 2.75 cm, we saw through 3 sides, leaving one wide side untouched. We close the ends of the profile pipe with it, having previously cut an opening on the opposite wide side.

Long-lasting discs for angle grinders on AliExpress at a discount - http://alii.pub/61bjly

We step back from the edge with the slot 16 cm and at a length of 12 cm we make parallel slits on the wide side on top with a step of 0.5 cm. Next to the slots we make a rectangular cutout. We weld the ends of the workpiece.

We drill three holes in the plate with a diameter of 1.6 cm and get three parts: square, with ends bent in one direction along the cuts and similar to the second, but with an elongated base.

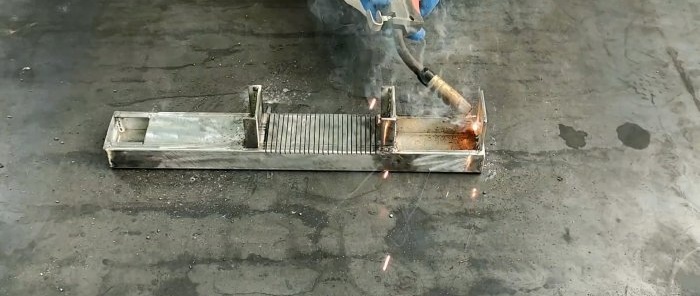

We insert the part by extension into the rectangular cutout, flush with the inner side until it stops in the profile pipe, and weld it so that the bent ends are directed towards the system of slots.

We place the part with the bent ends on the pipe after the slots and also weld it. Place the square at the end of the rectangular cutout in the profile pipe and weld it. All three holes in the parts must be coaxial.

We cut a piece 11.5 mm long from the profile rectangular pipe. After cutting and the necessary cuts, slots and welds, we get a part with a closed end at 45 degrees and a rectangular cutout at the end of the long side of the pipe.

We place the resulting part with a cutout in the long base on the end of a profile pipe with a square cutout and perform welding.

We cut two 26 cm long blanks from a 3x3 cm square pipe profile and weld them transversely to the smooth side of the rectangular pipe blank at an equal distance from the edges.

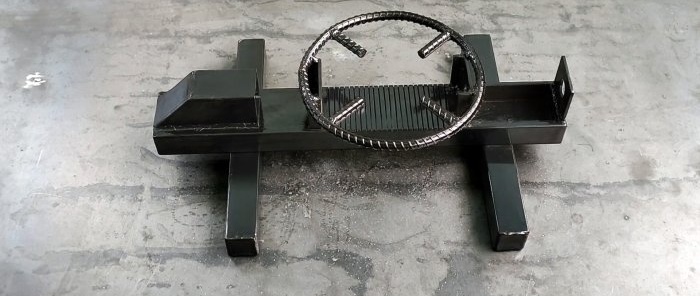

From the reinforcement we weld a stand for dishes in the form of a circle and four pins inside, evenly spaced in a circle. We wrap the stand around the vertical parts located along the edges of the slot system and weld. We paint a knot with dimensions 10×26×40 cm.

We place a square of sheet metal on the nut and use a rounded punch to squeeze out a hemisphere.At its bottom, using a smaller-diameter spherical punch, we make another protrusion, the top of which is ground with a grinder until we obtain a hole equal to the diameter of the sewing needle.

We place a blank of a round pipe 40 cm long into the base of the hemisphere and weld it. By cutting off the protrusions of the square plate, we get a pipe with a spherical end and a small hole in the center. We weld a nut to the other end of the pipe.

Welding electrodes for general purposes on AliExpress at a discount - http://alii.pub/606j2h

We place a shorter piece of fittings with a rounded and cross-shaped cut at the end into the pipe, then a spring and screw in the tap fitting.

We pass the tube with the rounded end through the hole in the square and bring it to the box. We hang a container of diesel fuel from the tripod in an inverted position, and connect the end of the tube to the inlet fitting of the closed tap.

We pour flammable liquid into the profile pipe and set it on fire to heat the round tube along its entire length. Carefully open the tap and ignite the diesel fuel vapor through the slots.

After the combustion has stabilized, we begin cooking. To turn off the stove, just close the tap.

Watch the video

Similar master classes