How to make an electric drive for a bicycle without electronics

Converting a regular bike to an electric one will make you more mobile with less effort. Such a transformation does not require special knowledge, professional skills or high costs. Any adult can handle this job.

Will need

Materials:

- pedal-powered bicycle;

- steel two-stage rod;

- DC motor;

- steel rectangular plate with holes;

- chain tensioner;

- clamp with button holder;

- non-latching button;

- metal box for batteries;

- 2 batteries, etc.

Tools: pliers, lathe, electric welding, adjustable wrench, soldering iron with solder, etc.

The process of converting a regular bicycle into an electric one based on a DC motor and a motorcycle chain.

We disconnect the chain by removing the fixing plate (pin) on the lock link. We knock the large sprocket off the pedal axis.

On a lathe we bore its central hole, corresponding to the diameter of the inner hole of the bearing on the small sprocket.

We weld the ends of each of the four spokes of the large sprocket to the small one on both sides.

We remove the standard sprocket from the rear wheel of the bicycle and replace it with a large one with a small sprocket with a bearing welded into it.

We install the wheel with the large sprocket in place and secure it there in the normal manner along with the two-legged step. We wrap the chain around the large sprocket and fix the pin on the lock link.

We grind the two-stage rod to the diameter of the small sprocket. We drill a hole in the center, cut off the required length and make a transverse hole in an area with a large diameter.

We insert the resulting two-stage bushing into the hole of the small sprocket and secure it by welding. We put the sprocket on the shaft of the DC motor and secure it with a fixing screw.

We weld a rectangular plate with holes to the top of the trunk, to which we fasten with bolts or simply weld the base of the electric motor.

We install the chain tensioner and fix it to the frame by welding.

We put a clamp with a button holder on the bicycle handle and secure it with a screw. We secure the button to the holder with a nut.

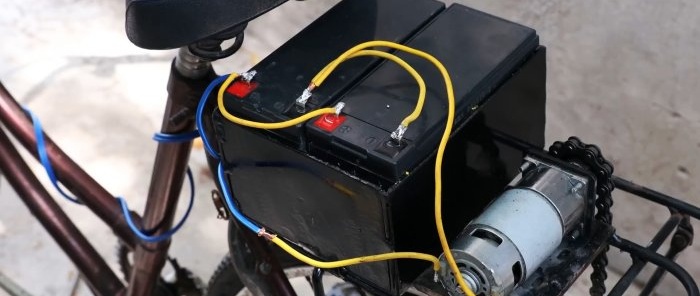

We weld a metal box for two batteries to the trunk between the electric motor and the seat, the wires of which are connected to each other and to the engine by soldering. The motor and batteries, in turn, are connected by a wire to the button.

When you press the button, voltage from the batteries is supplied to the electric motor and rotation through the small drive sprocket is transmitted by a chain to the large driven sprocket and the rear drive wheel. If you release the button, the chain breaks and the motor stops turning the wheel.

Welding electrodes for general purposes on AliExpress at a discount - http://alii.pub/606j2h

Watch the video

Similar master classes