5 precious tips when working with silicone, glue, sealant

Silicone is widely used in industry, technical equipment, medicine, and also in households for sealing and lubrication. Even utensils are made from food-grade silicone in which food can be prepared without harm to human health. Below are life hacks that will make working with this material easier and increase the efficiency of its use.

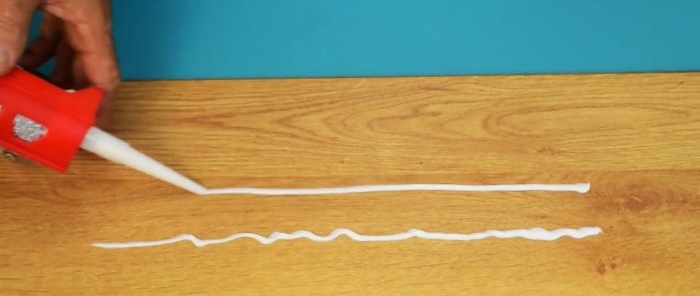

1. How to carefully apply a strip of silicone to the surface

If you lack experience, applying a neat strip of silicone to the surface is not so easy. After all, you need to hold the pistol with the tube with one hand, and press the trigger with the other.

To facilitate this operation, we drill a hole at the end of the gun and attach a small self-aligning furniture wheel in it.

It makes it easy to maintain the straightness of movement of the gun with the tube, which is the main condition for accurate work.

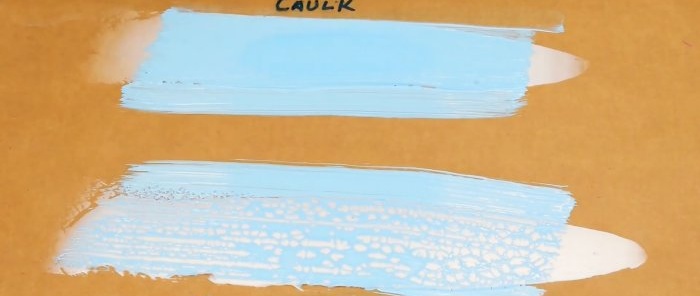

2. How paint applies to the surface of universal silicone and silicone mastic

Apply a strip of universal silicone and silicone mastic to the horizontal surface. We level them with a spatula and apply paint with a brush.

On the surface of universal silicone, the paint applies unevenly, but on the surface of silicone mastic - evenly, in a continuous layer.

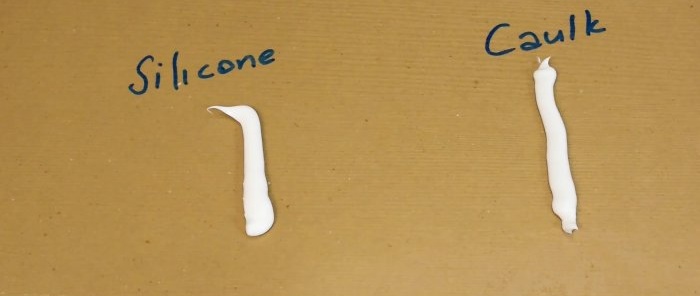

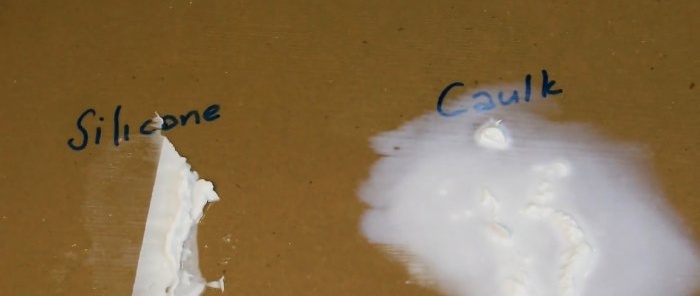

3. How do universal silicone and silicone mastic react to water?

Squeeze out a little universal silicone from the tubes onto a flat surface and next to it - silicone mastic. Spray them with water from a spray bottle. When stirred with a spatula, silicone mastic shows its solubility in water.

At the same time, universal silicone is not diluted in water.

4. How to reliably seal the gap behind a faucet that is installed close to the wall

Since the gun with the tube is quite large in diameter, it is not possible to seal the gap behind the faucet installed close to the wall. Getting out of a difficult situation is easy. It is necessary to put several tips on top of each other on the tip of the tube, then the tube with the base of the gun will be higher than the mixer and sealing the gap behind it will not be difficult.

5. How to reliably and aesthetically seal the joint between a vertical and horizontal surface

Apply silicone sealant along the entire length of the joint and moisten it with liquid soap. Then we cut off the top of the empty tube and narrow the cut end in one place to the height of the applied layer of sealant.

We use this place along the entire length of the silicone sealant, removing excess. The remaining sealant takes on a neat shape and provides additional sealing.