8 life hacks for the workshop

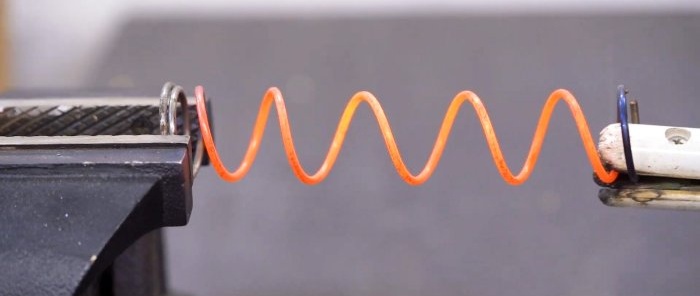

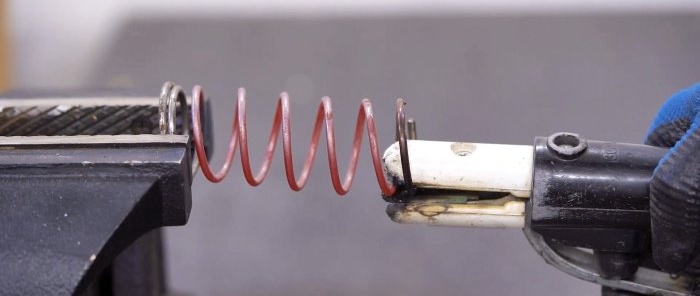

How to straighten a spring using a vice and a welding machine

We connect the mass and the electrode holder to the ends of the spring, heat it until red and pull it out into a slightly wavy wire. First, clamp one end of the spring in a vice.

How to fix a screw in a larger hole

To secure a screw in a large hole in a piece of wood, separate the filter from the cigarette, cut the outer shell and place it in the hole. We cut off the protruding part and soak it with superglue.

We wait for the glue to harden and screw in the screw.

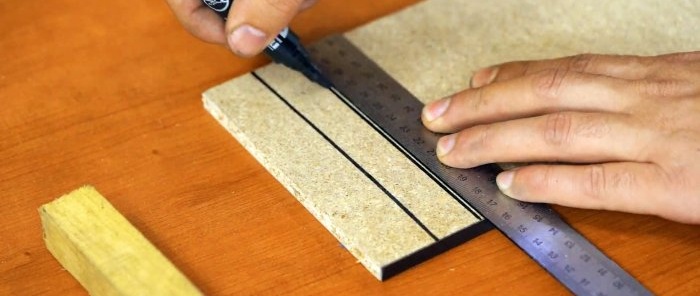

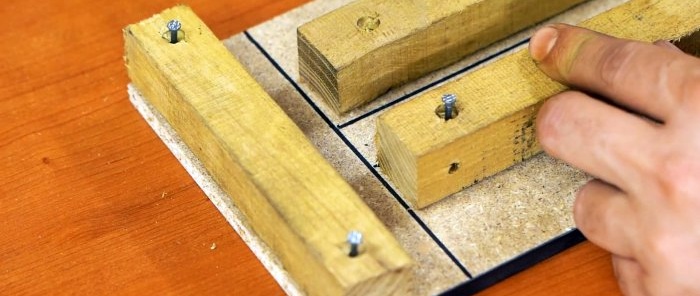

How to make a clamp from wooden blocks for fastening boards at right angles

We fasten 3 wooden blocks to the chipboard strip with nails. We place one transversely along the edge of the chipboard strip, and the other two are fastened symmetrically to the center of the strip and parallel to each other. The distances between the bars must be no less than the thickness of the boards. We place the first shield between the parallel bars, resting it against the transverse bar.

We place the second shield between the transverse beam and the end of the longitudinal one until it touches the first shield. We connect the panels with self-tapping screws or self-tapping screws.

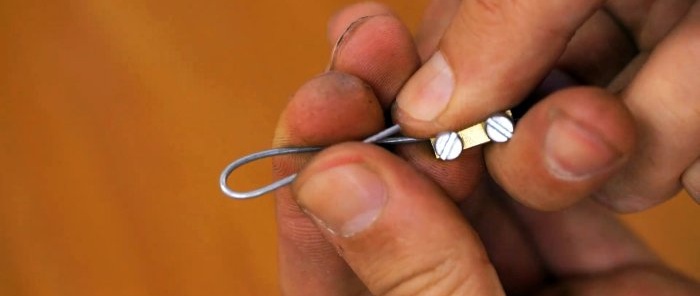

How to make a loop from a terminal block to connect wires

We separate one element from the terminal block and remove the contact assembly from it - a brass tube with two screws. We insert the end of the wire into the contact tube with the screws turned out, bend it 180 degrees and again insert the end into the contact tube on the other side, leaving a loop outside. Tighten the screws on the contact tube. The resulting loop will be a reliable fastening for hooking the extension spring.

How to make a powerful cutting product for a jigsaw from a metal cutting blade

We apply a jigsaw file to the metal blade in the longitudinal direction just below the teeth in a vice and use a grinder to form a fastening unit similar to a jigsaw saw.

We attach the metal blade to a jigsaw and use it to cut metal.

How to bend a U-shaped metal profile at 90 degrees

We draw a transverse line along the back of the profile. From its end along the edge we lay a line equal in length to the first one. We connect the resulting point with the upper end of the transverse line. We continue the ends of the transverse and diagonal lines along the narrow side of the profile. We cut the profile along the drawn lines. Cut out the narrow side between the edge cuts. We bend the profile all the way and get an angle of 90 degrees. A triangular fragment of one part of the profile covers the back of the other. We drill a hole in them and fasten them with a rivet.

How to fix a gas burner with a pin and a plumbing clamp with a nut

We screw a pin into the wooden base, secure it with a nut and screw on the second nut.

We screw half of the plumbing clamp with a nut onto the end of the stud and place the gas burner in it along the power belt on the body. We cover the power belt from above with the second half of the clamp and tighten the coupling bolts. Now both hands are free, which makes the work easier and faster.

How to make a sieve for sifting sand from a plastic bottle

We make a system of holes on the side surface of the plastic bottle, and a rectangular cutout on the opposite side. Pour sand of different fractions into it and sift it.

As a result, the small fraction of sand will end up on the outside, and the large fractions will remain inside the bottle.

Watch the video

Similar master classes