A simple device will allow you to easily move a massive workbench or rack when needed

Move bulky furniture in a room or a heavy workbench in a workshop is not so easy, and the floor can be damaged. By attaching rubber wheels to these products that lower and rise, any furniture or workbench can be easily moved with one hand.

Will need

Materials:

- wooden blocks 32×67 mm;

- wood glue;

- screws are different;

- rubber wheels for furniture Ø 75 mm;

- hinges 63×30 mm;

- corner 40×3 mm;

- bolts 5×40 mm, 5×65 mm;

- washers;

- extension spring.

High-quality and durable drills on AliExpress at a discount - http://alii.pub/5zwmxz

Tools: thicknesser, core, ruler, marker, clamp, drill, vice, grinder, flat file, etc.

Manufacturing process of a system for easy movement of heavy products

We select the length of the wooden blocks based on the place of their application. We mark the centers of the holes in the corners on a short block. We lay it on the end of a long block, align it, clamp it with a clamp and drill holes with a countersink.We put the bars on glue and fasten them with screws.

We attach a rubber furniture wheel to a short block so that when turning it does not extend beyond the ends of the bars, and also secure it with screws.

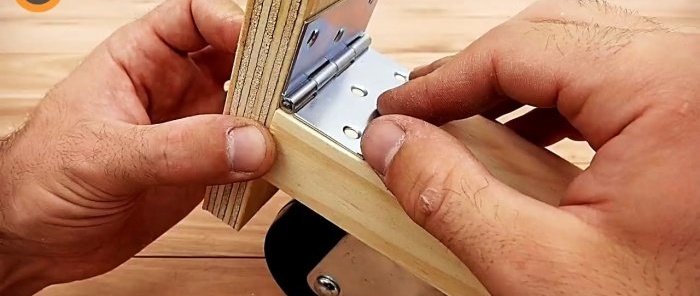

We attach a universal loop to the end of the long bar with screws so that the free plate in a vertical position does not extend beyond the edge of the bar.

From a 40x3 mm corner we cut out a latch according to the markings with the given dimensions, remove the burrs, trim the corners and round the edges with a file. We mark and drill two holes of different diameters.

Long-lasting discs for angle grinders on AliExpress at a discount - http://alii.pub/61bjly

We measure 80 mm from the end of the long bar, apply a latch, draw a line and mark the place for screwing in a 5x40 mm bolt to the length of the thread.

We rest the latch against the bolt so that there is a gap of at least 5 mm between the corner flange fragment and the block. We screw in a screw to the right of the bolt, but not all the way. We insert the end of the compression spring into the small hole on the latch.

We pass a bolt with a smooth part under the head and a washer through the hole in the latch, put 3 washers on the back side of the bolt and fasten the latch to the block so that it can turn. We put the other end of the spring on the bolt.

We mount the second furniture wheel and hinge on a shorter block without a short block and latch. We round the upper edge of the free end of the block with sandpaper.

We'll show you how to use the system on the workbench. To do this, we place stops under the legs of the workbench. We put a long block on top of a short one and place it between the legs so that the wheels do not touch the floor, and we fix the free wings of the hinges with screws to the legs of the workbench.

We compress the bars with a clamp and screw a 5x65 mm bolt with a smooth part under the head into the bottom bar in the corner of the latch.In this position, the wheels rest against the floor and the legs are suspended, so the workbench rolls freely and easily from place to place.

Having installed the workbench in the right place, press the latch with your foot and remove it from engagement with the 5x65 mm bolt. Under the action of the elastic forces of the rubber wheels, the bars rotate at a certain angle, and the legs of the workbench are lowered to the floor, occupying a stable position.