How to make a motorbike based on a lawn mower engine

If you install a motor on a bicycle with a pedal drive, its capabilities expand, you don’t have to waste muscular energy, you will be able to cover long distances and save time on moving. To equip a bicycle with a motor drive, you need certain knowledge, experience and qualifications.

Will need

Materials:

- bicycle "STELS" model 335 or similar;

- 4-stroke engine with a volume of 35 sq.cm;

- second rear wheel;

- gearbox with gear ratio 1:5;

- large sprocket with 74 teeth;

- chain with 8 mm pitch;

- metal plate;

- corner with shelf and two extended nuts, etc.

Tools: wrenches, calipers, lathe, welding, hammer, grinder, vice, drill, dremel, etc.

The process of installing a motor drive on a bicycle in the form of a 4-stroke engine from a lawn mower

We will make the bicycle with front-wheel drive, so instead of the usual wheel we will install a rear wheel, which has free wheeling. Then with the engine off bike can roll by inertia and without much resistance from the chain and gearbox.

Gearbox install on the output shaft engine. Its gear ratio is chosen to be 1 to 5, since the wheel diameter is 71 cm.

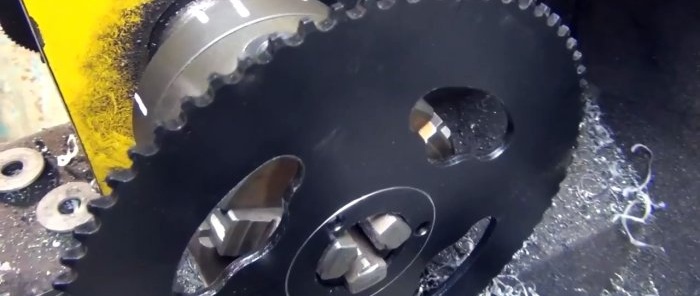

For the same purpose, the sprocket has 74 teeth. We will weld it to the small sprocket.

Place the chain with a pitch of 8 mm between the wheel and the front fork horn. To prevent the chain from touching the fork when rotating, the large sprocket will have to be placed on the inside of the small one. To do this, we make a corresponding hole in the center of the large star.

We remove the wheel from the front end, remove the small sprocket and fit the large one to a seat with a diameter of 48 mm. It can be seen that the hole needs to be bored out a little to a size of 48 mm.

We weld the small sprocket to the large one, first checking the alignment. We grind the welds and paint them with spray paint. We put the sprockets on the wheel and fasten them in the normal way.

To the big one put the sprocket on the chain. Attaching to the engine gearbox, and for attaching them to the frame bicycle We fasten a rectangular steel plate of the required dimensions to the gearbox with five bolts.

We bend the edges of the plate to perform the functions of stiffeners.

Using the bolt securing the front fender to the frame, we attach a corner with a shelf with two holes and high nuts welded to the bottom.

We vertically weld a strip with a protrusion along one edge with two holes to the plate with stiffening ribs on one side. As a result, we received a bracket for attaching the engine and gearbox to the bicycle frame.

We fasten the bracket to the corner with the shelf with two bolts, screwing them into the elongated nuts. We screw the gearbox to the bracket with engine. Sprockets on a gearbox with 11 teeth and a wheel with We connect 74 teeth with a chain.

We attach studs between the wheel axle and the bracket on both sides. Use it to tension the chain.We install the throttle control lever on the bicycle handlebar and begin road testing.

The motorbike showed excellent results in operation.

Watch the video

Similar master classes