How to convert a kitchen blender into an engraver

A common situation is that the blender is working, but its attachments are broken, and it is impossible to find and buy replacements for them. In this case, it can be converted into an engraver, which is done simply and quickly.

First you need to disassemble the blender body. The screws holding it together are usually located under rubber or plastic pads, which are simply removed. Most likely the screw heads are made for a screwdriver with curly slots. In this case, it is better to use it, since in the future everything will have to be put back together and if the edges on the heads are licked off with a regular screwdriver, then it will not be possible to tighten the screws again.

After opening the case, you need to remove the board and motor. After this, the adapter is removed and thrown out from the motor shaft to the nozzle retainer, along with the retainer itself.

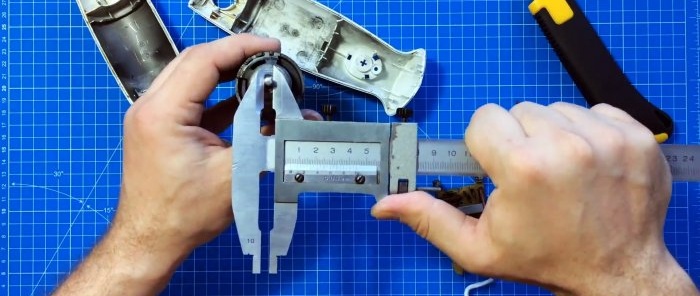

Instead, a drill chuck of a suitable size is installed on the shaft. It can be quick-clamping or designed to be clamped with a key. The main thing is that it is fixed to the shaft with side screws.

Next, you need to modernize the switching system.The standard blender button only works when pressed.

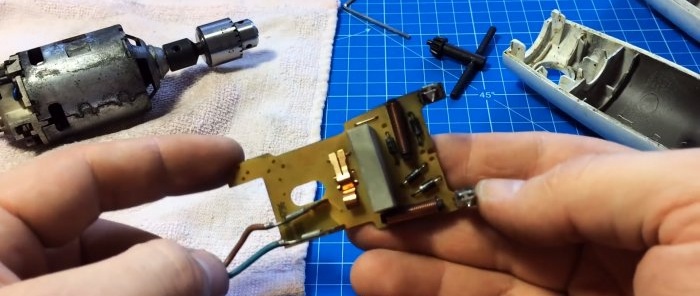

This is unacceptable for an engraver. If you constantly press it, it will be uncomfortable to work. In this regard, you need to remove it from the board. Instead, 2 wires are soldered in. They are soldered onto the contacts of a key switch or toggle switch. The switch itself cuts into the blender body from the back side, there is just free space there.

If you don’t want to deal with soldering, you can leave the standard button. In the future, it is simply pressed with electrical tape and the engraver will be started by plugging the plug into the socket. This is inconvenient, but if you don’t have a soldering iron or a suitable button, you can do it this way.

Before reassembling, you should wipe the inside of the case, and then put the motor and board back in place. If the embedded button does not fit well, it can be strengthened from the inside with hot glue. The housing may not be able to snap over the chuck due to its size, in which case the plastic will need to be filed down with a file.

The resulting engraver can work not only with light equipment, but also with fairly heavy drills, grinding stones, and saw blades. The blender engine is designed to handle loads that are orders of magnitude greater than those that an engraver usually has to deal with, so there should be enough power reserve.

Materials:

Blender conversion

First you need to disassemble the blender body. The screws holding it together are usually located under rubber or plastic pads, which are simply removed. Most likely the screw heads are made for a screwdriver with curly slots. In this case, it is better to use it, since in the future everything will have to be put back together and if the edges on the heads are licked off with a regular screwdriver, then it will not be possible to tighten the screws again.

After opening the case, you need to remove the board and motor. After this, the adapter is removed and thrown out from the motor shaft to the nozzle retainer, along with the retainer itself.

Instead, a drill chuck of a suitable size is installed on the shaft. It can be quick-clamping or designed to be clamped with a key. The main thing is that it is fixed to the shaft with side screws.

Next, you need to modernize the switching system.The standard blender button only works when pressed.

This is unacceptable for an engraver. If you constantly press it, it will be uncomfortable to work. In this regard, you need to remove it from the board. Instead, 2 wires are soldered in. They are soldered onto the contacts of a key switch or toggle switch. The switch itself cuts into the blender body from the back side, there is just free space there.

If you don’t want to deal with soldering, you can leave the standard button. In the future, it is simply pressed with electrical tape and the engraver will be started by plugging the plug into the socket. This is inconvenient, but if you don’t have a soldering iron or a suitable button, you can do it this way.

Before reassembling, you should wipe the inside of the case, and then put the motor and board back in place. If the embedded button does not fit well, it can be strengthened from the inside with hot glue. The housing may not be able to snap over the chuck due to its size, in which case the plastic will need to be filed down with a file.

The resulting engraver can work not only with light equipment, but also with fairly heavy drills, grinding stones, and saw blades. The blender engine is designed to handle loads that are orders of magnitude greater than those that an engraver usually has to deal with, so there should be enough power reserve.

Watch the video

Similar master classes

Particularly interesting

Comments (0)