Upgrading an energy-saving lamp to LED No. 1

Many thanks to the manufacturers of modern energy-saving lamps. The quality of their products constantly makes us think and pushes us to new technical solutions.

This time we will consider the topic of converting a failed energy-saving lamp into an LED one. Today we'll take a more traditional route using a driver for LED, but... The most interesting part of the remodeling is itself Light-emitting diode.

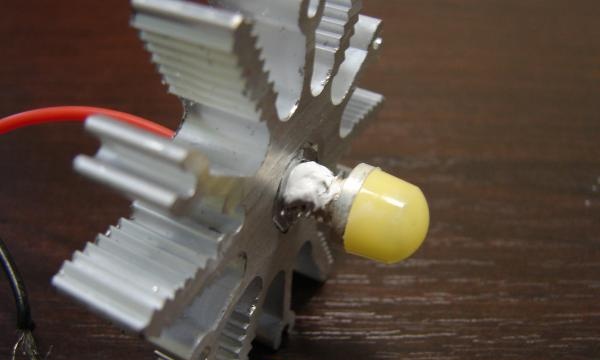

The other day I came across several samples of the Chinese electronics industry. These LEDs are interesting in themselves, although they do not have outstanding characteristics. But one thing is that given Light-emitting diode provides a 360-degree beam pattern, takes it to a whole new level and gives us a great tool for modernizing lighting systems.

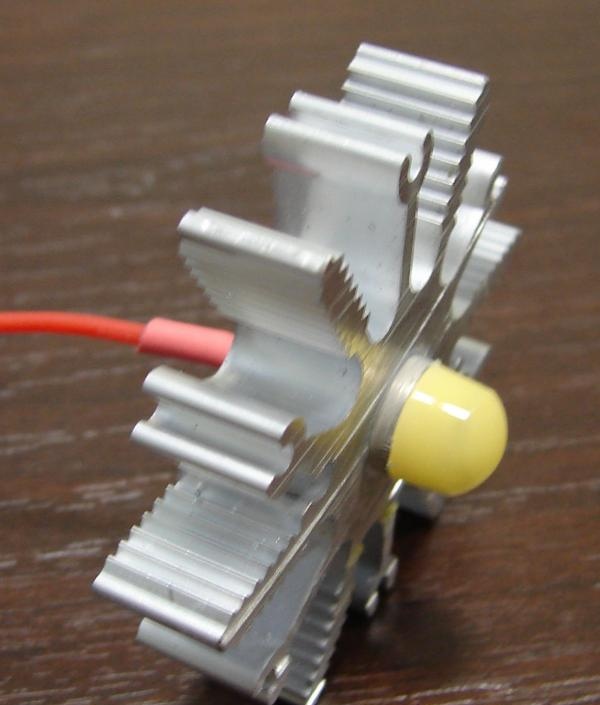

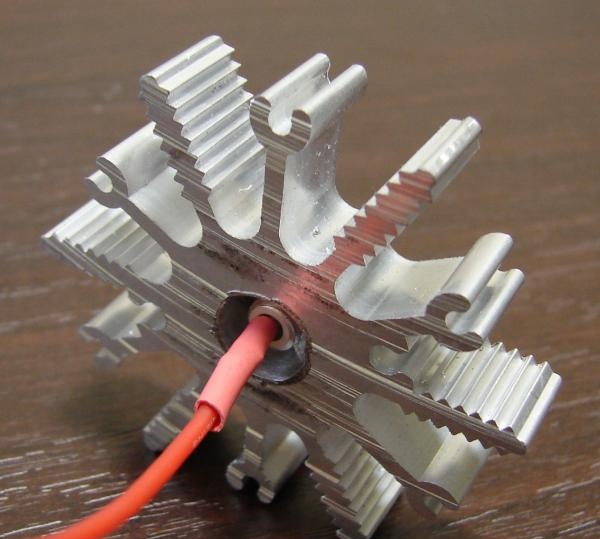

As a radiator, I used the aluminum universal profile AP888, already known from the previous article, produced by Yug-Service LLC. Unfortunately, I only had a piece of it a little over 10mm thick. There was a fear that LED 9 W power may not be enough. But the desire to conduct an experiment won out.

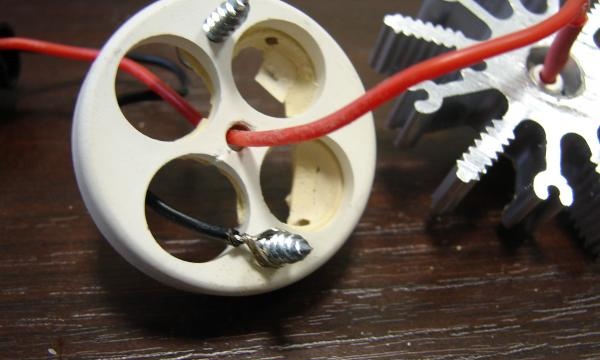

A small drawback of this profile in relation to the new LED is that the central hole is 8 mm in diameter, and the thread of the “tail” of the LED is M6.

The easiest way out:

- drill the hole to 10 mm;

- screw the bolt into the M6 nut;

- Carefully, hitting the head of the bolt with a hammer, press the nut into the profile. The bolt is needed so as not to accidentally jam the threads in the nut.

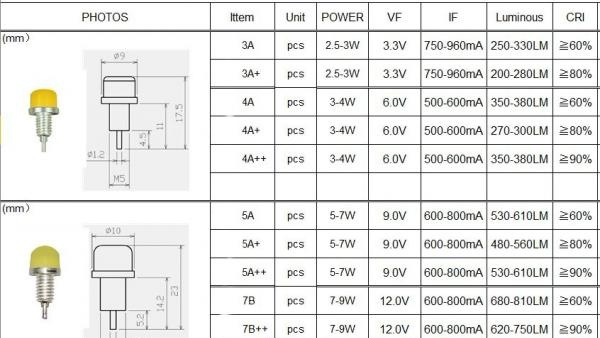

LED 7V, power 7-9 W, 12 V, 600-800 mA. As a driver, I used a widely used 700 mA driver for three LEDs from the same Chinese manufacturer.

Then, as always, everything is simple. We know how to disassemble an energy-saving light bulb, the main thing is not to break the bulb. And we prepare the entire kit for assembly.

1. Drill holes in the cover of the base housing to attach the radiator and wires.

2. Solder the positive wire of the driver to the central contact of the LED. Don't forget to first thread it through the radiator and the base cover.

3. Apply heat-conducting paste (KTP-8) to the thread of the LED and screw it into place. We attach the cover of the base housing to the radiator.

4. The negative wire of the driver must be connected to the radiator.

5. Solder the driver network wires into the base.

6. Collect everything into one.

7. The upgraded lamp is ready for use.

As for my concerns about the LED overheating due to the insufficient heatsink size, we can say that they turned out to be groundless. The temperature at the “LED-radiator” point after several hours of operation stopped at around 59-62 ºС (ambient temperature 23 ºС). In principle, this is acceptable, but if the radiator is increased by 5-10 mm, then you don’t have to worry about anything at all.

Everything is simple, beautiful and most importantly – accessible and not expensive.

Similar master classes

Particularly interesting