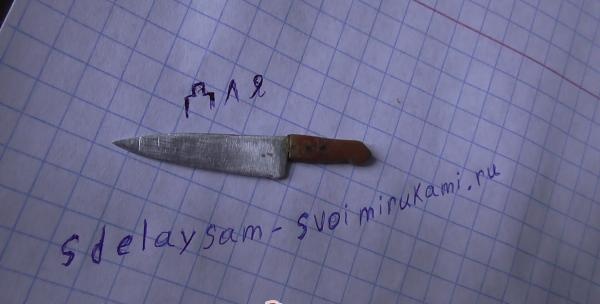

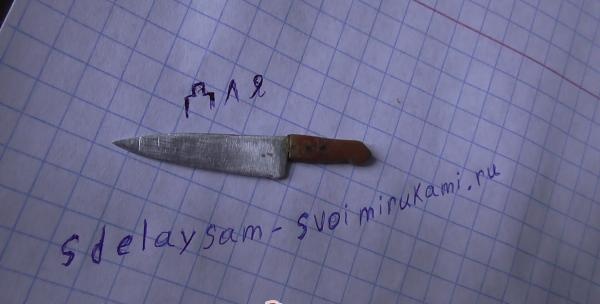

Mini copy knife

Good day everyone, today we will create a mini copy of the knife.

We will use a table knife as a sample.

To make it we will need:

A thin plate of steel or tin, even a tin can will do, you will also need a small block of wood, as tools - files of different sections and sandpaper of different diameters.

Let's get started.

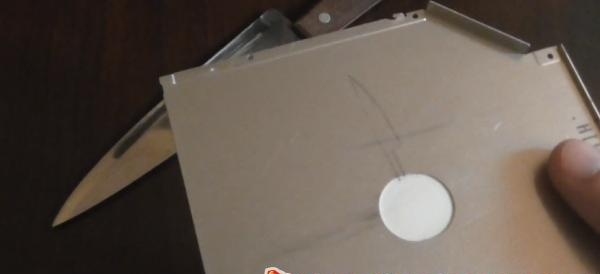

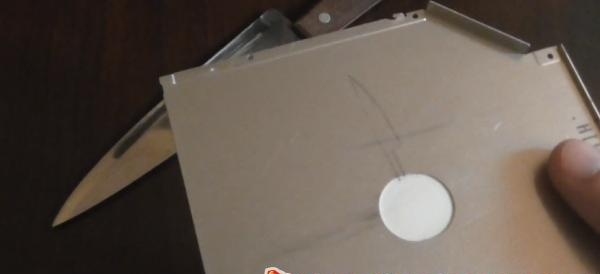

First of all, we need to draw a copy of the future knife on a steel plate; we draw it together with part of the handle, so that in the future it would be more convenient to secure it in a wooden handle.

After the sketch is ready, we cut out or saw out the future workpiece, it doesn’t matter if it turns out with bent edges, this can be easily corrected with the help of a hammer and a small anvil.

Now, using a fine file, we will trim the corners and irregularities, following the original.

Next, let's move on to the handle itself. Let's cut off a small rectangle from the block, slightly larger than the finished handle.

We shape it with a file and bring it to the desired state using fine sandpaper, then insert the handle into the glue knife and apply it for a super moment.

If your knife model has rivets, they can be easily made from pieces of thick piercing.And then glue them to the handle.

All that remains is to polish the blade with GOI paste and, if desired, varnish the handle.

Good luck with your DIY projects.

Video of the manufacturing process:

We will use a table knife as a sample.

To make it we will need:

A thin plate of steel or tin, even a tin can will do, you will also need a small block of wood, as tools - files of different sections and sandpaper of different diameters.

Let's get started.

First of all, we need to draw a copy of the future knife on a steel plate; we draw it together with part of the handle, so that in the future it would be more convenient to secure it in a wooden handle.

After the sketch is ready, we cut out or saw out the future workpiece, it doesn’t matter if it turns out with bent edges, this can be easily corrected with the help of a hammer and a small anvil.

Now, using a fine file, we will trim the corners and irregularities, following the original.

Next, let's move on to the handle itself. Let's cut off a small rectangle from the block, slightly larger than the finished handle.

We shape it with a file and bring it to the desired state using fine sandpaper, then insert the handle into the glue knife and apply it for a super moment.

If your knife model has rivets, they can be easily made from pieces of thick piercing.And then glue them to the handle.

All that remains is to polish the blade with GOI paste and, if desired, varnish the handle.

Good luck with your DIY projects.

Video of the manufacturing process:

Similar master classes

Particularly interesting

Comments (2)