Kitchen shelf

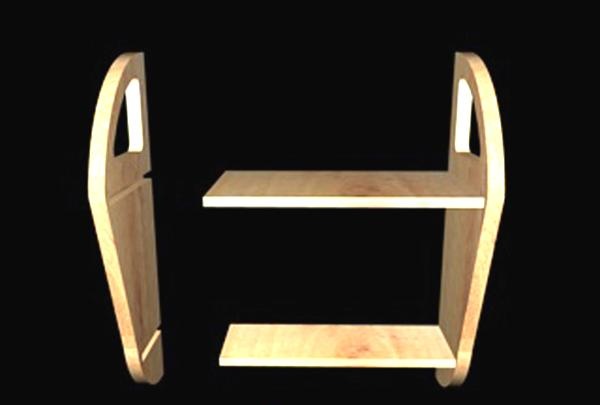

There are places in the kitchen where there is not enough space for a full shelf, but something similar would be nice. For example, there is usually not much space between the gas water heater and the stove, and there are also pipes running on top. Just for such inconvenient places, I suggest making a small shelf for useful little things - salt, spices, etc.

You will need:

- plywood 16 mm thick;

- thin boards or plywood 10 mm thick;

- pencil, ruler, compass;

- drill, drill bits;

- jigsaw;

- chisel 10 mm wide, hammer;

- a scraper made of a hacksaw blade or a shoe knife;

- PVA glue;

- plywood 3 mm thick;

- nails, screws;

- varnish, brush, sanding paper.

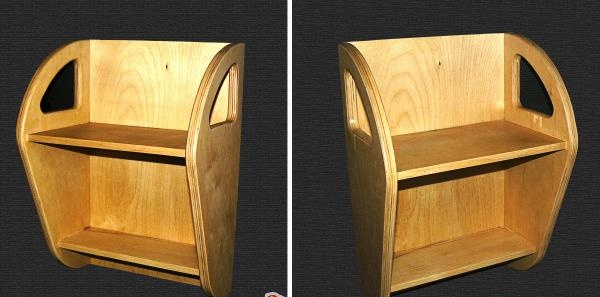

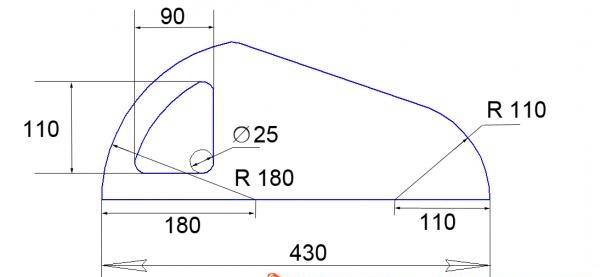

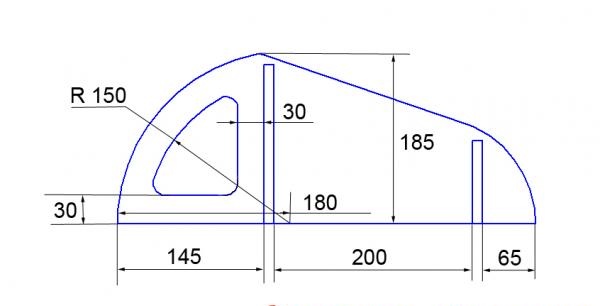

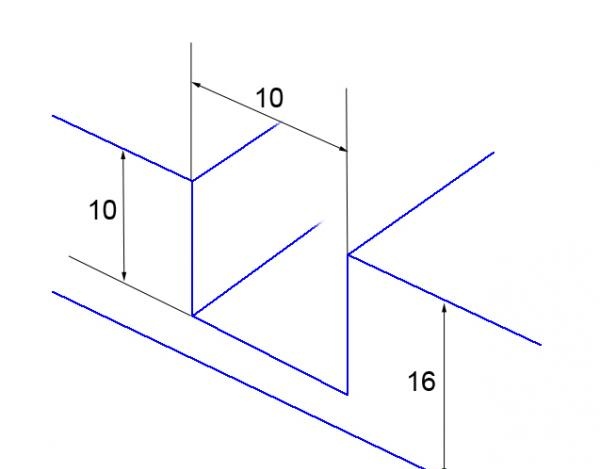

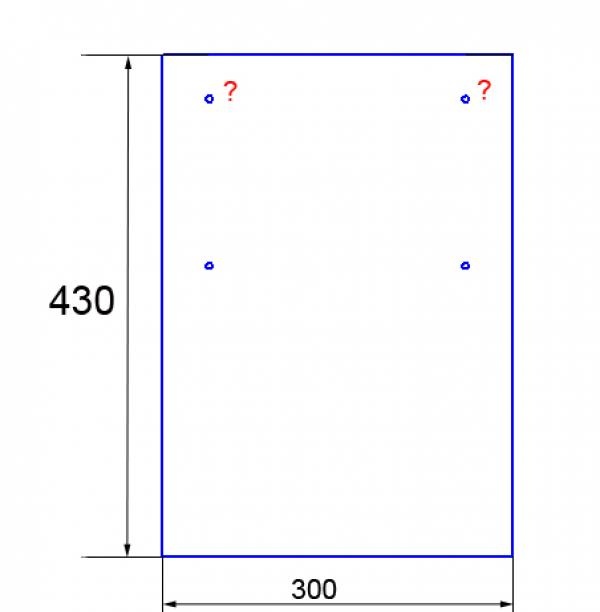

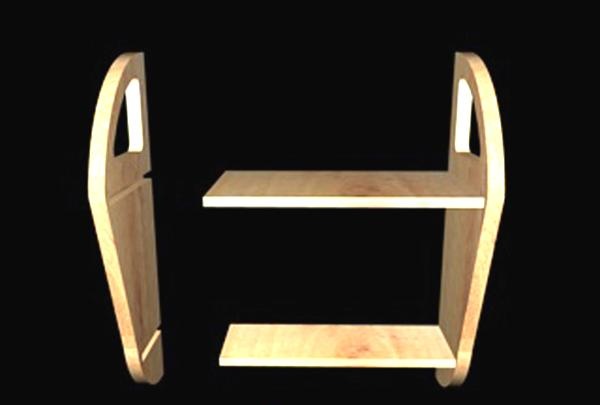

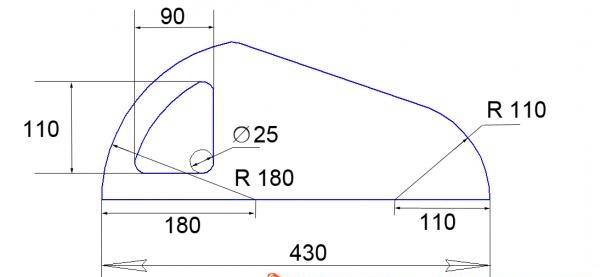

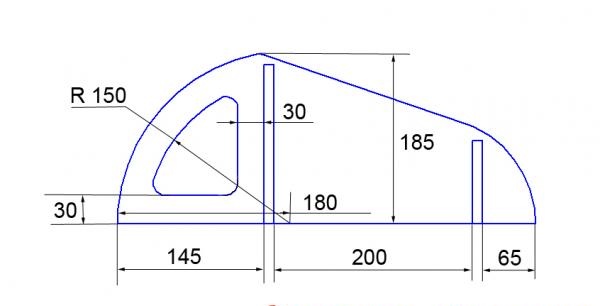

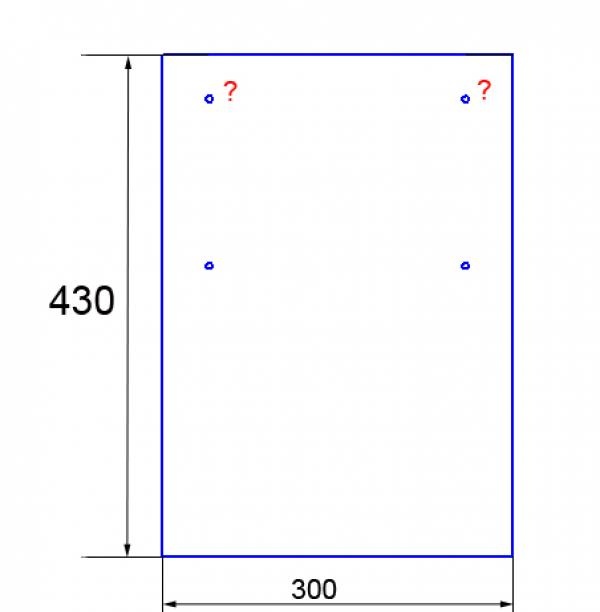

The shelf consists of two racks, two shelves of different widths, and a wall at the back. The racks have decorative cutouts. The racks are mirror-symmetrical, so the dimensions are indicated only for the right rack.

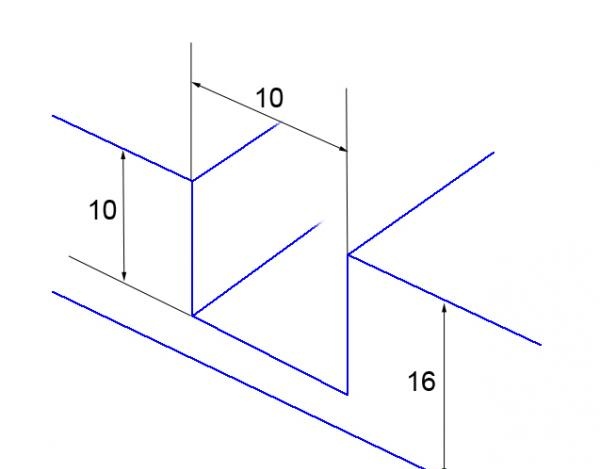

We mark it according to the drawing, drill out the decorative cutout in the corners with a feather drill, then cut it out with a jigsaw and a nail file for curved cuts. To install the shelves you need to make grooves. To ensure that the edges of the grooves are neat and even, use a shoe knife or scraper, using a metal ruler as a guide, to scratch the top layer of plywood along the border of the future groove.The scraper (tooth) is made from a piece of blade for a hacksaw for metal (Fig. 5). We do the rest of the sampling with a chisel. The grooves are 1 cm deep.

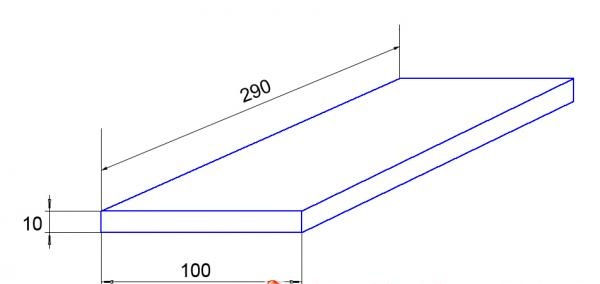

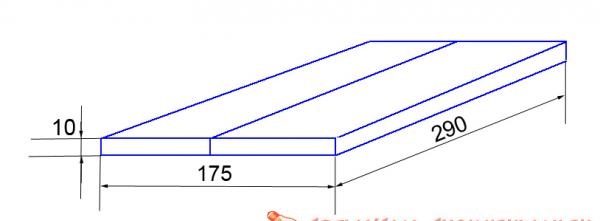

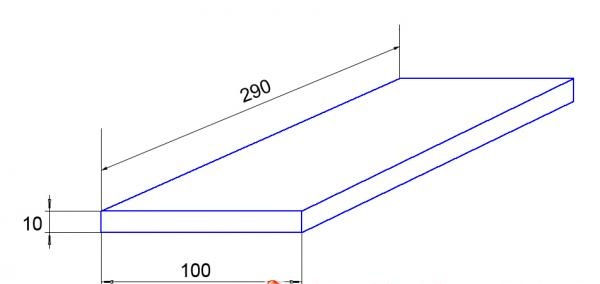

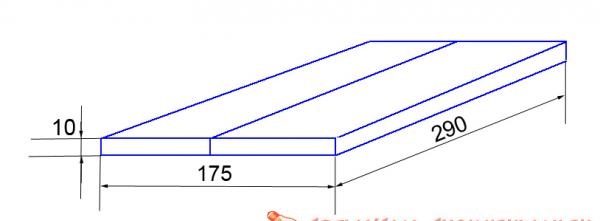

Rectangular shelves made of thin boards 1 cm thick or multilayer plywood also 1 cm thick.

If you don’t have a board of sufficient width, you can glue two narrower ones - apply glue to the ends, squeeze, place on a flat surface and press with a weight. After drying, cut with a jigsaw to the required size.

For the back wall we take three-layer plywood. We pre-drill holes for wall mounting. The holes can be either above the top shelf or below it.

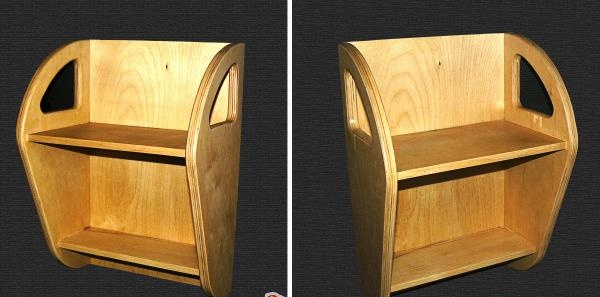

When all the parts are made, they need to be sanded. The outer parts of the racks and the decorative opening should be slightly rounded. If necessary, fill up chips and defects with putty of the appropriate color and clean them. For better adhesion (stickability), prime the grooves and ends of the shelves with a weak PVA solution. On a flat surface we assemble the structure using glue.

To prevent the shelf from sticking to the base, it is better to carry out assembly on a piece of polyethylene (at least a cut bag). After the glue has dried, if necessary, we clean the joints and varnish the entire shelf. We nail the prepared back wall with small nails or fasten it with small screws.

Once again we coat the entire structure with varnish. All. Can be mounted on the wall.

You will need:

- plywood 16 mm thick;

- thin boards or plywood 10 mm thick;

- pencil, ruler, compass;

- drill, drill bits;

- jigsaw;

- chisel 10 mm wide, hammer;

- a scraper made of a hacksaw blade or a shoe knife;

- PVA glue;

- plywood 3 mm thick;

- nails, screws;

- varnish, brush, sanding paper.

The shelf consists of two racks, two shelves of different widths, and a wall at the back. The racks have decorative cutouts. The racks are mirror-symmetrical, so the dimensions are indicated only for the right rack.

We mark it according to the drawing, drill out the decorative cutout in the corners with a feather drill, then cut it out with a jigsaw and a nail file for curved cuts. To install the shelves you need to make grooves. To ensure that the edges of the grooves are neat and even, use a shoe knife or scraper, using a metal ruler as a guide, to scratch the top layer of plywood along the border of the future groove.The scraper (tooth) is made from a piece of blade for a hacksaw for metal (Fig. 5). We do the rest of the sampling with a chisel. The grooves are 1 cm deep.

Rectangular shelves made of thin boards 1 cm thick or multilayer plywood also 1 cm thick.

If you don’t have a board of sufficient width, you can glue two narrower ones - apply glue to the ends, squeeze, place on a flat surface and press with a weight. After drying, cut with a jigsaw to the required size.

For the back wall we take three-layer plywood. We pre-drill holes for wall mounting. The holes can be either above the top shelf or below it.

When all the parts are made, they need to be sanded. The outer parts of the racks and the decorative opening should be slightly rounded. If necessary, fill up chips and defects with putty of the appropriate color and clean them. For better adhesion (stickability), prime the grooves and ends of the shelves with a weak PVA solution. On a flat surface we assemble the structure using glue.

To prevent the shelf from sticking to the base, it is better to carry out assembly on a piece of polyethylene (at least a cut bag). After the glue has dried, if necessary, we clean the joints and varnish the entire shelf. We nail the prepared back wall with small nails or fasten it with small screws.

Once again we coat the entire structure with varnish. All. Can be mounted on the wall.

Similar master classes

Particularly interesting

Comments (0)