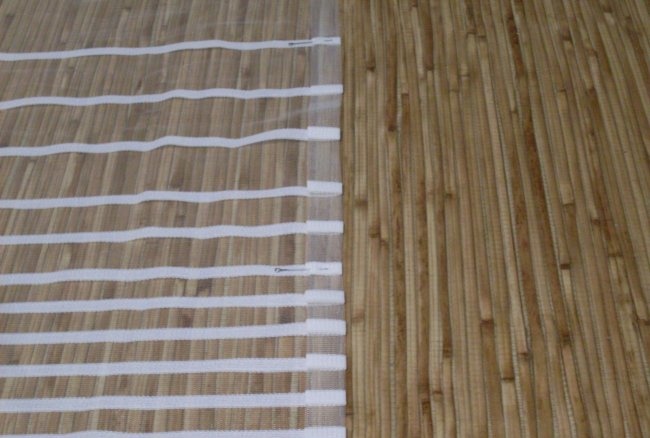

We sew tulle from mesh with our own hands

Quite often, different types of mesh are used as material for tulle. The material is very beautiful, but capricious, requiring special attention and approach in processing. However, this does not mean at all that only masters in a professional curtain salon can sew tulle from mesh. It is quite possible to cope with such a task on your own, in the comfort of your home. Simply carefully study the properties of your mesh and follow the instructions below.

First of all, the sides of the tulle are processed. As a rule, this is a regular hem seam with a closed cut, when finished, the width is from 2 to 3 cm (depending on the density of the fabric).

There are two types of meshes - soft plastic and hard. The first ones are quite difficult to hem, especially without preliminary wet-thermal preparation, the second ones are somewhat easier.

In any case, it is best to prepare the sides in advance, and only then machine stitch. To do this, you need to carefully, without stretching along the length, iron the side sections of the tulle onto the wrong side by 4-6 cm. Then the seam allowance needs to be folded inward by half the width.To prevent the fabric from twisting during sewing, the seam allowances must be secured with pins every 15-20 cm.

After this, you need to sew the sides of the tulle at a distance of 2 mm from the inner folded edge.

At the stage of machine stitching, the following difficulties may arise: the machine chews the edge of the fabric at the beginning of the stitch, the stitch loops, and skipping stitches occurs.

To prevent the machine from chewing the edge of the mesh, you need to sew without fastening; at the beginning of the stitch, you need to leave fairly long ends of the threads, by which you can slowly pull the fabric, helping its movement.

The stitch length should not be short. Then the sewing process will progress much easier and faster.

It is better to loosen the thread tension a little. Then the finished side seam will not tighten.

If the stitching starts to loop, or skipping stitches appear, you may need to use a knitting needle.

If this does not help, or does not help much, you need to use a zig-zag stitch instead of a straight stitch.

It is advisable, of course, before starting work to try sewing an unnecessary piece of tulle to make sure that the stitching will turn out beautiful and of high quality.

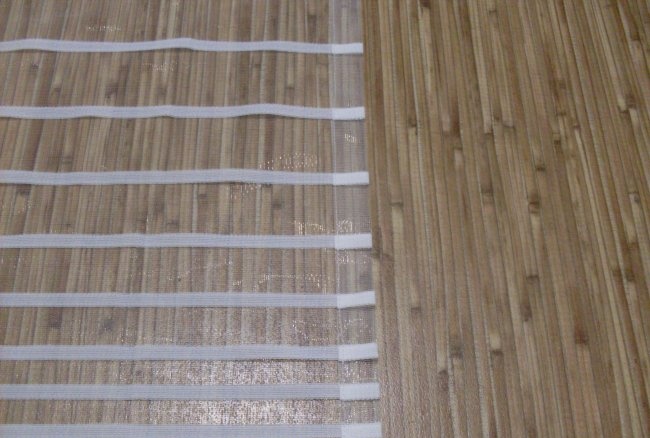

If the tulle has a pattern, such as stripes, you should be careful to ensure that it matches.

Then you need to process the bottom of the tulle.

The allowance for processing it must first be ironed towards the wrong side by 6 cm, and then again - by half the width.

Then the bottom of the tulle needs to be stitched.

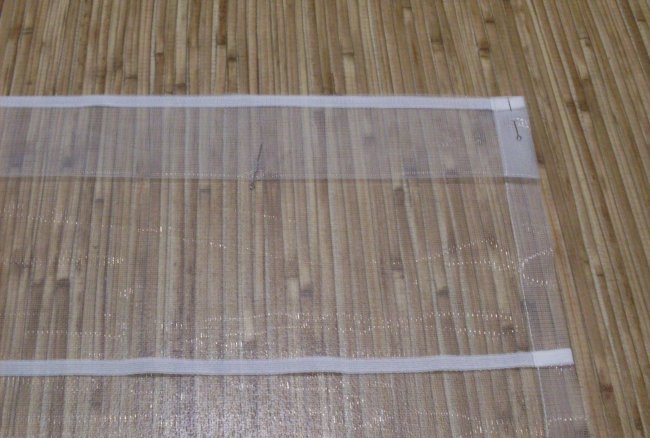

From the bottom of the tulle up you should set aside the desired length (for example, from the floor to the bottom of the hook), from this mark up you need to set aside two more widths of the extrafora (curtain braid) plus 2 cm. Everything else needs to be cut off.

The processing allowance must be ironed towards the wrong side of the fabric over the entire calculated width, and then in half.

Currently, extrafor is produced with 2, 3 or 4 holding threads, designed to tighten the tulle across the width to the required length of the cornice. If it has 4 threads, an additional stitch is usually placed in the middle between them. In other cases, it is enough to sew the extrafor with two lines, only along the edges.

First, the extrafor must be stitched along the upper edge, departing 1 cm from the top of the tulle. Then, to avoid twisting of the fabric during sewing, its lower edge is secured with pins.

Then they sew a line along the bottom edge of the curtain tape and remove the pins.

On one end edge, on the wrong side of the braid, the holding threads need to be tied together, and on the other, pulled out to the front side of the braid to make it convenient to pull the tulle together.

Finally, the tulle is pulled to the desired width, the threads are tied, wound into a small skein and hidden under the extrafor.

If necessary, the tulle is ironed in finished form.

Mesh tulle on figured extrafor is ready!

First of all, the sides of the tulle are processed. As a rule, this is a regular hem seam with a closed cut, when finished, the width is from 2 to 3 cm (depending on the density of the fabric).

There are two types of meshes - soft plastic and hard. The first ones are quite difficult to hem, especially without preliminary wet-thermal preparation, the second ones are somewhat easier.

In any case, it is best to prepare the sides in advance, and only then machine stitch. To do this, you need to carefully, without stretching along the length, iron the side sections of the tulle onto the wrong side by 4-6 cm. Then the seam allowance needs to be folded inward by half the width.To prevent the fabric from twisting during sewing, the seam allowances must be secured with pins every 15-20 cm.

After this, you need to sew the sides of the tulle at a distance of 2 mm from the inner folded edge.

At the stage of machine stitching, the following difficulties may arise: the machine chews the edge of the fabric at the beginning of the stitch, the stitch loops, and skipping stitches occurs.

To prevent the machine from chewing the edge of the mesh, you need to sew without fastening; at the beginning of the stitch, you need to leave fairly long ends of the threads, by which you can slowly pull the fabric, helping its movement.

The stitch length should not be short. Then the sewing process will progress much easier and faster.

It is better to loosen the thread tension a little. Then the finished side seam will not tighten.

If the stitching starts to loop, or skipping stitches appear, you may need to use a knitting needle.

If this does not help, or does not help much, you need to use a zig-zag stitch instead of a straight stitch.

It is advisable, of course, before starting work to try sewing an unnecessary piece of tulle to make sure that the stitching will turn out beautiful and of high quality.

If the tulle has a pattern, such as stripes, you should be careful to ensure that it matches.

Then you need to process the bottom of the tulle.

The allowance for processing it must first be ironed towards the wrong side by 6 cm, and then again - by half the width.

Then the bottom of the tulle needs to be stitched.

From the bottom of the tulle up you should set aside the desired length (for example, from the floor to the bottom of the hook), from this mark up you need to set aside two more widths of the extrafora (curtain braid) plus 2 cm. Everything else needs to be cut off.

The processing allowance must be ironed towards the wrong side of the fabric over the entire calculated width, and then in half.

Currently, extrafor is produced with 2, 3 or 4 holding threads, designed to tighten the tulle across the width to the required length of the cornice. If it has 4 threads, an additional stitch is usually placed in the middle between them. In other cases, it is enough to sew the extrafor with two lines, only along the edges.

First, the extrafor must be stitched along the upper edge, departing 1 cm from the top of the tulle. Then, to avoid twisting of the fabric during sewing, its lower edge is secured with pins.

Then they sew a line along the bottom edge of the curtain tape and remove the pins.

On one end edge, on the wrong side of the braid, the holding threads need to be tied together, and on the other, pulled out to the front side of the braid to make it convenient to pull the tulle together.

Finally, the tulle is pulled to the desired width, the threads are tied, wound into a small skein and hidden under the extrafor.

If necessary, the tulle is ironed in finished form.

Mesh tulle on figured extrafor is ready!

Similar master classes

Particularly interesting

Comments (0)